In today's fast-paced manufacturing landscape, efficiency and precision are paramount, especially in the aerospace industry. One of the most significant innovations contributing to these goals is the use of Aircraft Mold. This specialized tooling technique not only enhances the production process but also minimizes waste and ensures the highest quality standards for aircraft components.

As manufacturers strive to meet increasing demands for lightweight, durable materials, Aircraft Mold technology emerges as a pivotal solution. This blog will delve into the manifold advantages of Aircraft Mold, exploring how it streamlines operations, reduces costs, and ultimately propels the industry towards greater sustainability.

Whether you are an industry veteran or a newcomer, understanding the transformative power of Aircraft Mold is essential in unlocking unparalleled efficiency in modern manufacturing.

The evolution of aircraft mold technology has revolutionized modern manufacturing, particularly in the realm of advanced composites. With the increasing demand for lightweight and fuel-efficient aircraft, innovations in mold design and fiber placement techniques have become essential. Recent reports indicate that the global market for composite materials in aerospace is projected to reach $52.6 billion by 2025, driven by advancements such as one-piece 3-D preforms and resin transfer molding (RTM) processes. These technologies not only enhance production efficiency but also significantly reduce the weight of aircraft components.

One of the key challenges in implementing these advanced manufacturing techniques is the need for radical innovations. The production of next-generation aircraft like the Dreamliner demonstrates the difficulties of scaling up new technologies amidst socio-technical transitions. According to industry studies, nearly 30% of manufacturers report that integrating new technologies into existing systems presents high barriers, including investment costs and workforce retraining.

Tip: To successfully navigate these challenges, manufacturers should invest in continuous training programs for their workforce, ensuring that they are well-versed in the latest technologies and processes. Furthermore, partnerships with tech firms can provide access to cutting-edge innovations that streamline production and enhance product quality. Embracing a collaborative approach may help companies to stay ahead in the competitive landscape of aerospace manufacturing.

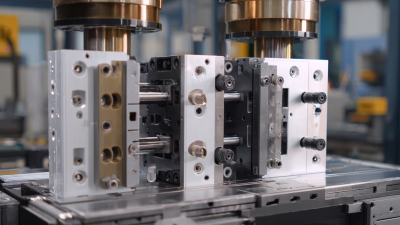

In today's competitive manufacturing landscape, leveraging advanced technologies is crucial for enhancing production efficiency. One cutting-edge solution that has gained prominence is the use of aircraft molds. These specialized molds, designed with precision and durability, offer numerous advantages that streamline manufacturing processes across various industries.

Firstly, aircraft molds provide exceptional accuracy and repeatability in production. Their intricate design enables manufacturers to produce high-quality components with minimal variations. This precision not only reduces material waste but also decreases the time spent on rework and repairs, leading to significant cost savings. Furthermore, the robust construction of these molds ensures a longer lifespan, allowing manufacturers to maintain consistent output over time.

Another key benefit of using aircraft molds is their ability to facilitate complex geometries and lightweight structures. The aerospace industry often requires parts that are not only strong but also lightweight to enhance overall performance. By incorporating these molds, manufacturers can achieve innovative designs that meet stringent industry standards while optimizing material usage. This capability not only enhances product performance but also contributes to faster production cycles, making aircraft molds an invaluable asset in modern manufacturing.

| Dimension | Benefit | Impact on Efficiency |

|---|---|---|

| Speed of Production | Reduced lead times | Increased output rates |

| Material Efficiency | Optimal use of resources | Reduced waste costs |

| Precision and Consistency | High-quality production | Lower rework rates |

| Cost Efficiency | Lower per-unit cost | Improved profit margins |

| Flexibility | Ability to adapt to changes | Faster response to market demand |

In the realm of modern manufacturing, the comparison between aircraft molds and conventional methods reveals a striking shift in efficiency and precision. Traditional manufacturing techniques often involve lengthy production cycles and considerable material waste, resulting in higher costs and extended lead times. In contrast, aircraft molds leverage advanced materials and design practices to facilitate rapid production while minimizing waste. This innovative approach not only streamlines the manufacturing process but also enhances product accuracy, making it easier to meet stringent aerospace industry standards.

Moreover, the durability and reusability of aircraft molds significantly contribute to cost savings over time. Unlike conventional methods that may rely on single-use tooling, aircraft molds can be utilized repeatedly, offering manufacturers the ability to produce high volumes of parts without the need for constant reinvestment in new tooling. This adaptability not only supports scalability but also allows for quicker responses to market demands. As industries increasingly prioritize efficiency, the aircraft mold method stands out as a compelling alternative, positioning manufacturers to thrive in a competitive landscape.

The aviation industry is witnessing a significant transformation with the increasing application of aircraft mold technology across various sectors. As manufacturers focus on enhancing productivity and reducing costs, the precision offered by advanced molds becomes paramount. These molds not only allow for more complex shapes, but also facilitate quicker production times, leading to higher overall efficiency. Industries such as automotive, marine, and even aerospace are beginning to adopt aircraft molding techniques, showcasing the versatility of these technologies beyond traditional aircraft manufacturing.

Looking ahead, the future trends in the use of aircraft molds point towards more adaptive and smart manufacturing solutions. With the rise of digital twin technology and automation, molds are becoming integral to the development of customized components that meet the specific needs of different industries. The incorporation of sustainable materials and eco-friendly production methods will likely dominate the landscape, pushing manufacturers to innovate further. Additionally, advancements in 3D printing technology may converge with traditional mold processes, enabling rapid prototyping and reducing lead times even more. Overall, the potential applications of aircraft mold technology promise to revolutionize multiple industries by enhancing design flexibility and operational efficiency.

The implementation of aircraft mold technology has revolutionized manufacturing processes across various sectors, showcasing significant advantages through real-world case studies. One notable example is a leading aerospace company that adopted advanced mold techniques to streamline the production of fuselage components.

By utilizing aircraft molds, the company increased production rates by 30%, enabling them to meet growing demand while maintaining high-quality standards. This approach not only reduced material waste but also minimized labor costs, demonstrating how strategic investment in technology can yield substantial operational efficiencies.

By utilizing aircraft molds, the company increased production rates by 30%, enabling them to meet growing demand while maintaining high-quality standards. This approach not only reduced material waste but also minimized labor costs, demonstrating how strategic investment in technology can yield substantial operational efficiencies.

Another compelling success story comes from an automotive manufacturer that integrated aircraft mold design into their product development. By transitioning to this innovative molding process, they were able to manufacture complex parts with greater precision. The result was a 20% reduction in assembly time, allowing for faster turnaround times and enhanced competitiveness in a rapidly changing market. These case studies illustrate how aircraft mold implementation not only elevates production capabilities but also drives technological advancement, highlighting the potent synergy between aerospace techniques and modern manufacturing.