In recent years, the mold market has experienced significant transformations, driven by shifts in consumer preferences, technological advancements, and regulatory changes. According to the latest report from MarketsandMarkets, the global mold market is projected to reach $XX billion by 2025, growing at a CAGR of XX% from 2020 to 2025. This growth underscores the importance of understanding current market dynamics and the necessity for businesses to adapt to evolving trends. The **Analysis of Mold Market Trends** reveals key insights into alternative solutions that are gaining traction, from sustainable materials to innovative manufacturing techniques. As industries increasingly prioritize eco-friendliness and efficiency, exploring these trends becomes crucial for stakeholders aiming to stay competitive. This blog will delve into these alternative solutions, highlighting the pivotal trends shaping the future of the mold market.

The mold market is experiencing significant transformations, driven by evolving consumer needs and advancements in technology. According to a recent report by Grand View Research, the global mold market size was valued at approximately $7.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is largely attributed to increased demand from various sectors, including automotive, consumer products, and healthcare, which seek innovative and efficient manufacturing processes.

One key trend shaping the current landscape is the shift towards sustainable mold-making practices. As industries strive to reduce their carbon footprint, manufacturers are exploring eco-friendly materials and processes. A study by MarketsandMarkets highlighted that the use of biodegradable and recyclable raw materials in mold production is projected to witness a significant rise, with an estimated increase of 30% by 2025. Additionally, there’s a growing emphasis on the adoption of digital tools and automation, allowing for enhanced precision and efficiency in mold design and production, ultimately contributing to cost reduction and improved turnaround times.

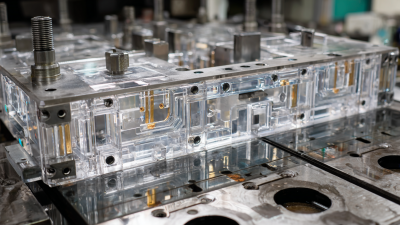

Emerging alternative solutions in mold manufacturing are reshaping the industry, especially with the introduction of digital metal sheet forming technology. This innovative approach, highlighted by notable developments at the recent IMTS exhibition, offers a cost-effective method for metal forming that can significantly improve production efficiency. Companies are increasingly seeking to adopt digital solutions that streamline their operations, reduce waste, and enhance precision in mold creation.

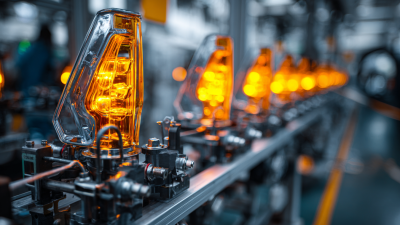

Moreover, as the mold market evolves, manufacturers must stay attuned to key trends affecting their practices. For instance, incorporating in-mold electronics is revolutionizing product design by enabling the creation of touch-sensitive surfaces directly within the mold. This reduces the need for additional components and cuts costs, making it an appealing option for producers looking to innovate while maintaining budget efficiency.

**Tips for Manufacturers**: Embrace digital technologies to automate processes and reduce labor costs. Stay ahead of the curve by investing in research and development for in-mold electronics to enhance product offerings. Finally, consider sustainable alternatives in material selection to meet increasing environmental regulations and consumer demand for eco-friendly products.

The mold production industry is undergoing significant transformation driven by several key trends. One of the foremost trends is the adoption of advanced materials, such as thermoplastics and composite formulations, which enhance durability and reduce production times. These materials not only improve the performance of molds but also contribute to sustainability efforts by minimizing waste and energy consumption during manufacturing processes.

Another trend is the integration of digital technologies into mold production techniques. The use of 3D printing has revolutionized prototyping and the creation of complex mold geometries that were previously unattainable with traditional methods. Additionally, the implementation of industry 4.0 principles, including smart manufacturing and IoT connectivity, enables real-time monitoring and data-driven decision-making, leading to enhanced efficiency and quality control.

Lastly, the growing emphasis on customization in consumer products demands more flexible and responsive mold production strategies. Manufacturers are increasingly focusing on short-run production capabilities and rapid changeover of molds to cater to varying consumer needs. This shift not only supports innovation but also allows for a more agile response to market changes, ensuring that businesses remain competitive in a fast-evolving landscape.

This chart illustrates the growth of various production techniques in the mold market over the past five years, highlighting key trends driving change.

The increasing focus on sustainability in the mold market is driving a significant shift toward the use of sustainable materials in mold design. These materials, often derived from renewable resources or designed to minimize environmental impact, offer numerous benefits that appeal to both manufacturers and consumers. By incorporating sustainable materials, companies can reduce their carbon footprint while also enhancing the lifecycle and durability of their products, leading to decreased waste over time.

In addition to environmental advantages, the adoption of sustainable materials in mold design aligns with the growing consumer demand for eco-friendly products. Today's consumers are more informed and concerned about the ecological impacts of their purchases, which influences their buying decisions. Businesses that prioritize sustainability not only meet these consumer preferences but also position themselves as leaders in a competitive market. This strategic move can foster brand loyalty and potentially open up new markets that prioritize sustainability, further embedding environmental responsibility into the core business model.

The mold industry is currently undergoing a significant transformation, driven by inventions that are reshaping the landscape. According to a recent report by MarketsandMarkets, the global mold market is projected to grow from $37.5 billion in 2022 to $51.7 billion by 2027, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth is largely attributed to advancements in materials technology, including the increased use of lightweight and durable materials for mold manufacturing. Notably, the adoption of 3D printing technology in mold production is allowing for more complex designs and reduced lead times, thereby enhancing efficiency and cost-effectiveness.

Moreover, the rising emphasis on sustainability is steering the industry towards eco-friendly mold solutions. A study by Grand View Research highlights that the use of biodegradable materials in mold production is expected to rise significantly, with the sustainable segment anticipated to generate over $10 billion in revenue by 2026. Innovations in processes are also emerging, such as the integration of smart technologies that enable real-time monitoring and predictive maintenance of mold equipment. These innovations not only optimize production but also help manufacturers reduce waste and improve overall operational efficiency, aligning with the global trend towards greener manufacturing practices.