In today's rapidly evolving global market, the demand for high-quality manufacturing solutions has never been greater. As buyers worldwide seek reliable and efficient tools for their production needs, the electric box mold emerges as a critical component in various industries. This blog will explore the best electric box mold options available while also highlighting alternatives that can provide the same level of functionality without compromising quality.

In the dynamic landscape of the electric box mold industry, global buyers are increasingly seeking innovative alternatives that not only meet their specifications but also enhance operational efficiency. According to a recent report by Allied Market Research, the global electric box mold market is projected to reach $1.2 billion by 2027, growing at a CAGR of 5.4% from 2020 to 2027. This significant growth is driven by the rising demand for energy-efficient products and the transition towards smart electrical systems.

Innovative materials and design methodologies are taking center stage in the development of electric box molds. For instance, the adoption of advanced polymers and composite materials has proven beneficial in enhancing durability and reducing weight, making products more versatile for various applications. A study from MarketsandMarkets highlights that the use of 3D printing technologies in mold manufacturing allows for rapid prototyping and greater customization, catering to specific market needs. As manufacturers continue to explore these cutting-edge solutions, global buyers are well-positioned to benefit from an evolving product lineup that aligns with sustainability and efficiency goals in the electric sector.

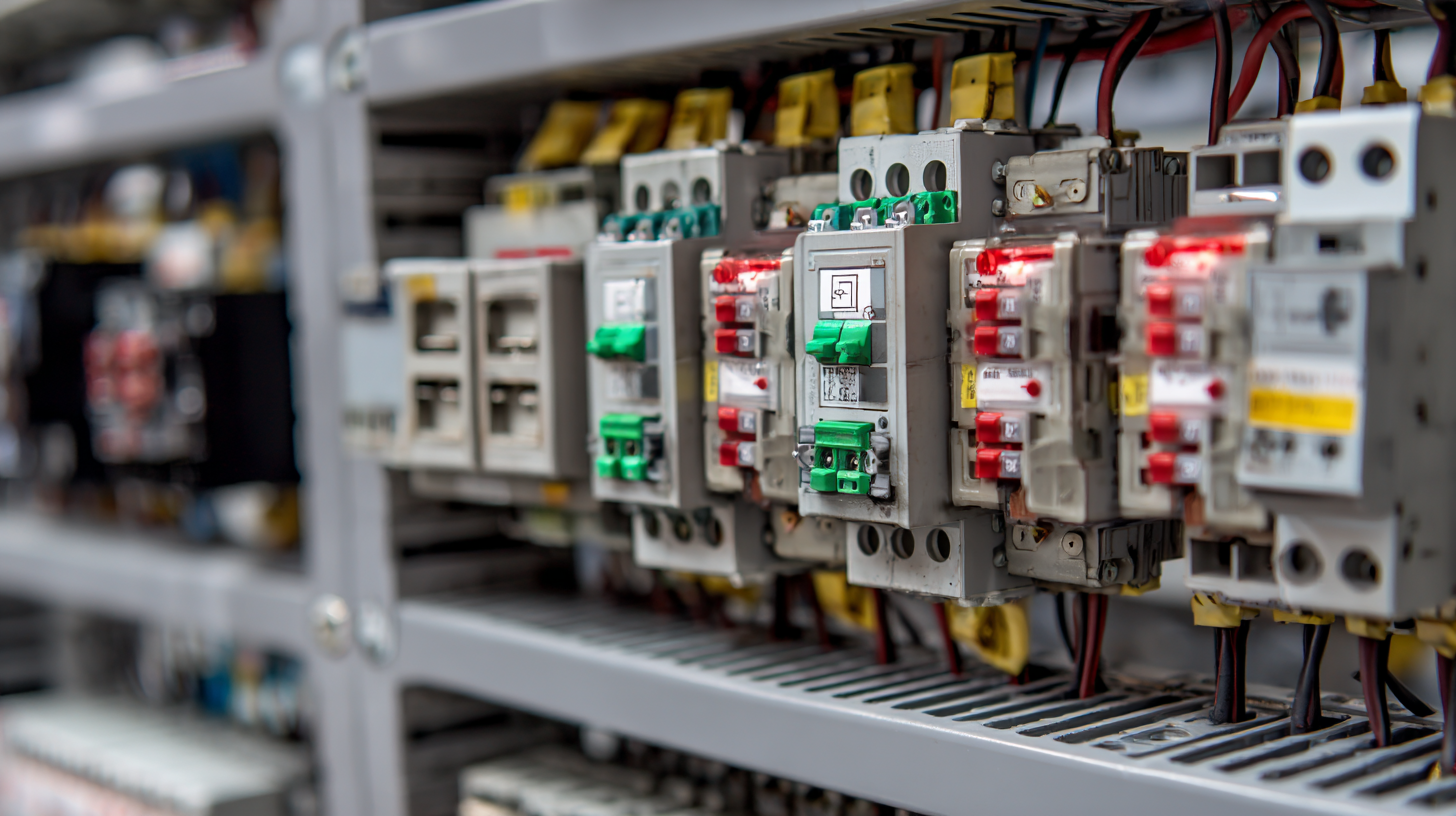

When selecting electric box molds, several critical factors come into play to ensure a reliable and effective choice for global buyers. First and foremost, material quality is paramount. The durability and resistance of the mold material to thermal and electrical stress can significantly impact the final product’s longevity. Buyers should opt for molds made from high-grade materials like reinforced plastics or metals, which can withstand harsh environments and repetitive use.

Another important consideration is the design and compatibility of the molds with existing manufacturing processes. It is essential to evaluate how well the mold design aligns with the specific requirements of the production line. Factors such as ease of use, maintenance, and the speed of the production cycle can hugely influence overall efficiency. Additionally, suppliers with a proven track record in providing customizable molds can offer a significant edge, allowing manufacturers to adapt the molds to their unique specifications.

Lastly, understanding the cost-effectiveness of electric box molds can lead to substantial savings in the long run. It's crucial to analyze not only the initial purchase price but also the potential for long-term durability and efficiency that can reduce operational costs. Weighing these factors will help global buyers make informed decisions, ensuring they choose the best electric box molds for their needs.

The growing awareness of environmental sustainability is reshaping the manufacturing landscape, particularly in the production of electric box molds. Traditional materials often used in these molds, such as plastic and metal, can contribute significantly to environmental degradation and pollution. In contrast, alternatives like bioplastics and recycled materials not only reduce waste but also lower carbon footprints during production. By embracing these innovative materials, manufacturers can play a crucial role in the global shift toward eco-friendliness.

Furthermore, the adoption of alternative electric box mold materials presents numerous environmental benefits. For instance, bioplastics derived from renewable resources biodegrade more easily than conventional plastics, thereby minimizing long-term waste in landfills. Similarly, recycled materials decrease the demand for virgin resources, reducing the energy and raw material consumption associated with production. These options not only enhance sustainability but also resonate with consumers who increasingly prioritize environmentally responsible products. As global buyers seek ways to align their purchases with eco-friendly values, the exploration of these alternatives becomes not just an ethical choice but a market necessity that could define the future of electric box mold manufacturing.

| Material Type | Thermal Stability | Environmental Impact | Recyclability | Cost Effectiveness |

|---|---|---|---|---|

| Bamboo Fiber | High | Low | Yes | Moderate |

| Recycled PVC | Medium | Moderate | Yes | Low |

| Biodegradable Polymers | High | Very Low | Yes | High |

| Natural Rubber | High | Low | Yes | Moderate |

| PLA (Polylactic Acid) | Medium | Low | Yes | Low |

In the competitive landscape of manufacturing, many international buyers are seeking cost-effective electric box mold solutions without compromising quality. According to a report by MarketsandMarkets, the global market for electric box molds is expected to grow at a CAGR of 4.3% from 2021 to 2026, driving the need for affordable yet reliable options. Manufacturers can leverage innovations in design and materials to reduce costs and enhance productivity, making such solutions increasingly attractive to global clients.

When considering alternatives, it is essential to focus on local suppliers who can offer shorter lead times and reduced shipping costs. Additionally, buyers should explore multi-cavity molds, which allow for the production of multiple parts in a single cycle, thus lowering the manufacturing cost per unit. One effective tip is to engage with suppliers who utilize advanced technologies, such as 3D printing, to produce prototypes quickly. This approach not only accelerates the design process but also allows for testing and modifications before full-scale production, ultimately saving time and resources.

Moreover, forming partnerships with manufacturers who prioritize sustainability can yield significant long-term savings. In fact, a study by McKinsey & Company noted that companies committed to sustainable manufacturing practices can achieve cost reductions of up to 30%. By investing in eco-friendly molds and production methods, buyers can not only reduce costs but also meet the growing demand for environmentally responsible products in the global market.

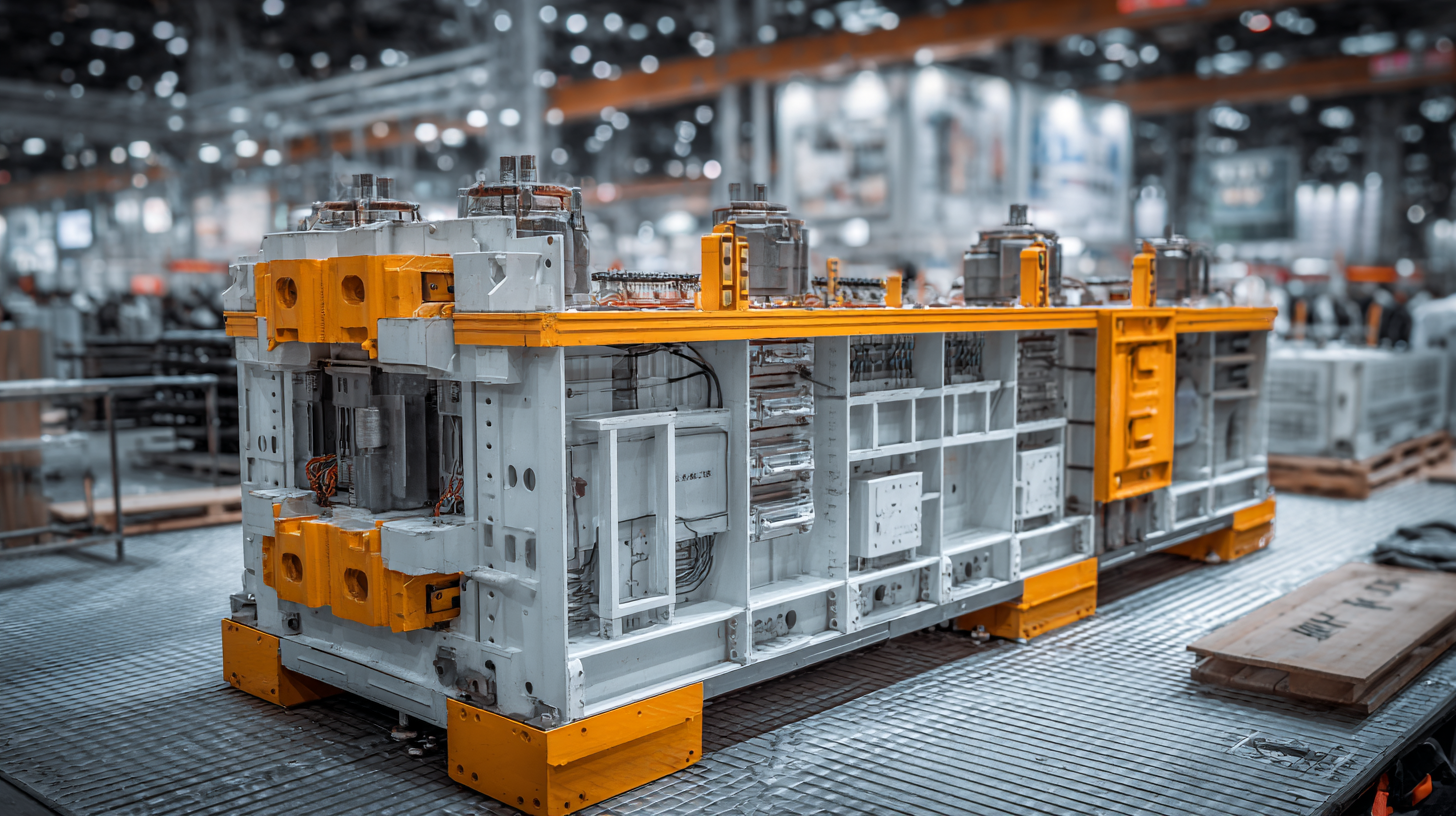

When considering the optimal choice for electric box molds, traditional molds have long been the go-to option due to their established reliability and performance. However, recent innovations have introduced alternative materials and designs that warrant closer examination. Traditional molds often use metals that can endure high temperatures and maintain shape under pressure, but they may not be as cost-effective or environmentally friendly. The heavy use of metal also complicates transportation and handling, making them less appealing for global buyers aiming for sustainability.

On the other hand, alternative electric box molds made from advanced composite materials or biodegradable plastics are gaining traction. These alternatives often provide similar levels of durability and thermal resistance while reducing weight and manufacturing costs. Moreover, they tend to be more adaptable to different production needs, allowing for custom designs that traditional molds may struggle to accommodate. The comparative performance of these options is crucial for buyers who are balancing factors like cost, environmental impact, and production flexibility—in an era where sustainability is increasingly prioritized on the global market.