In the automotive industry, the precision and quality of components are crucial. One key element is the "Automotive Headlight Mold." This mold shapes the headlights that illuminate our roads. According to Alex Thompson, a mold expert at Global Automotive Solutions, "The right mold makes all the difference in headlight performance."

Creating an Automotive Headlight Mold involves advanced techniques and materials. Designers must consider factors such as light distribution and aesthetic appeal. Often, the process is not as seamless as it seems. There can be challenges in achieving the right specifications. Mistakes in the early stages can lead to costly revisions later.

Reflecting on production, the importance of detail stands out. Each mold requires precision to ensure optimal functionality. However, imperfections can occur. These flaws remind us that refining processes is essential for success. In the end, the Automotive Headlight Mold is more than just a shape; it’s a vital part of vehicle safety and efficiency.

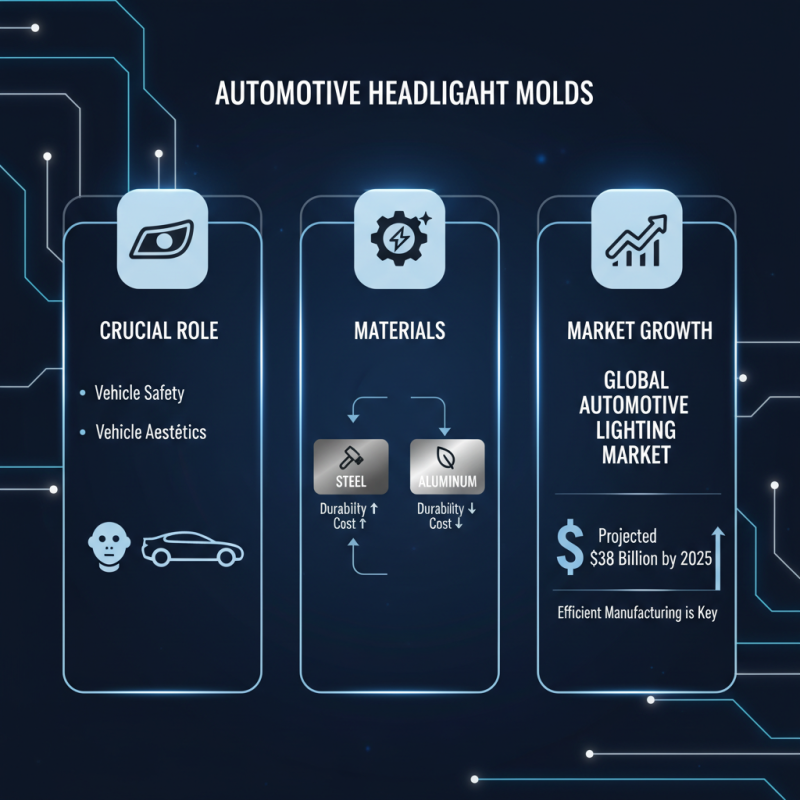

Automotive headlight molds play a crucial role in vehicle safety and aesthetics. These molds are typically made from high-quality steel or aluminum. The choice of material affects durability and cost. According to industry reports, the global automotive lighting market is projected to reach $38 billion by 2025. This growth emphasizes the importance of efficient manufacturing processes for headlight molds.

The creation of a headlight mold involves several steps. First, manufacturers design the mold using advanced software. This design phase is critical and often reveals potential flaws. It's essential to consider design specifications carefully. Any mistake here can lead to wasted resources and time. After approval, the actual mold is fabricated using CNC machines. These machines ensure precise dimensions, vital for fitting the headlight components perfectly.

Once the mold is crafted, it undergoes rigorous testing. Quality control checks help catch any imperfections that might affect performance. Continuous improvement is necessary, as even minor errors can lead to significant issues. Data indicates that nearly 17% of headlight units face quality challenges in production. Addressing these concerns early can save manufacturers from costly recalls. Ultimately, creating high-quality automotive headlight molds requires attention to detail and constant evaluation.

Automotive headlight molds play a crucial role in vehicle design. These molds create the outer shapes of headlights, which must meet both aesthetic and functional requirements. Designers often collaborate with engineers to ensure that the molds will produce headlights that are safe, durable, and visually appealing.

Creating these molds involves precision. Typically, they are made from steel or aluminum. The process starts with a detailed design. Advanced computer software helps visualize the final product. Once the design is approved, the mold is crafted through machining techniques. However, errors can occur during production. Sometimes, molds do not fit perfectly, requiring adjustments. This can delay the project and increase costs.

In vehicle design, headlights are more than just lights. They contribute to a vehicle's overall style. A well-designed headlight can enhance the look of a car. However, if the mold does not capture the intended design, the final product may disappoint. Designers often reflect on past projects to improve future designs, learning from mistakes to better inform their creative process.

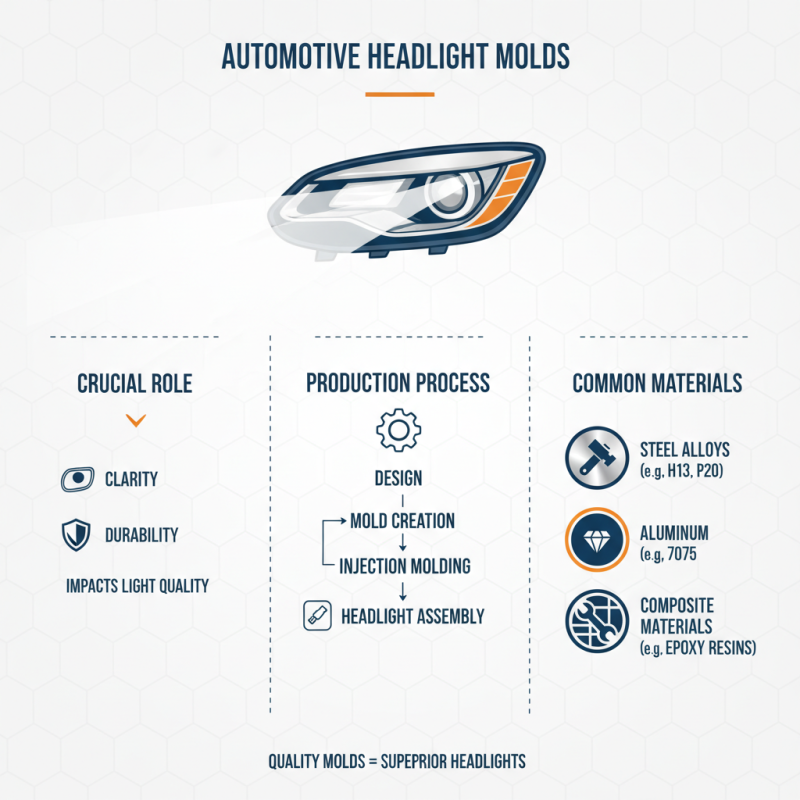

Automotive headlight molds play a crucial role in the production of vehicle headlights. The quality of these molds directly impacts the clarity and durability of the lights. Several materials are commonly used when manufacturing headlight molds.

Steel is often the primary choice due to its strength and durability. It can withstand high temperatures during the injection molding process. However, it is heavy and can be costly. Aluminum, on the other hand, is lighter and easier to work with. It provides good thermal conductivity but may not last as long under extreme conditions.

In addition to metals, epoxy resins are sometimes employed. They are lighter and can create complex shapes. Their surface finishes can be very smooth but may not be as robust as metal molds. Finding the right balance between these materials is vital. Each option has its flaws and strengths. Manufacturers must weigh their choices carefully.

The manufacturing process of automotive headlight molds is intricate. It begins with designing the mold, which requires precise measurements. Engineers use advanced software to create detailed models. These models are essential for ensuring proper fit and functionality.

Next, raw materials are selected based on durability and heat resistance. Common choices include aluminum and steel due to their strength. The chosen material is then heated and shaped using specialized machinery. This step demands attention to detail. Any errors in shaping can result in flawed molds.

Once the initial shaping is complete, the molds undergo a thorough quality check. Every imperfection must be identified. Flaws can lead to significant issues in production later on. After the inspection, final adjustments are made. This ensures the mold meets exact specifications. It's a challenging process, where continuous reflection on outcomes is vital for improvement.

Quality control in headlight mold production is critical. The process involves various testing phases to ensure durability and functionality. A study by the Automotive Industry Action Group reported that nearly 30% of defects in headlight molds can be traced back to inadequate quality checks. Each mold must withstand rigorous inspections, including pressure tests and thermal stability assessments. These tests reveal vulnerabilities that can lead to future failures.

The production involves using high-grade materials. Some of these materials have a tolerance level as fine as 0.01 mm. This precision is vital for achieving optimal lens clarity. However, many manufacturers struggle with achieving such accuracy consistently. Reports have shown that approximately 15% of produced molds fail to meet this standard. Addressing these shortcomings requires advanced technologies, such as 3D printing and computer simulation, to predict potential issues before they arise.

Quality control is not just about meeting specifications. It's also about understanding customer expectations. Many users expect bright, reliable headlights that enhance safety. Yet, a survey revealed that 25% of customers reported dissatisfaction due to poor mold quality. This feedback highlights the importance of continual improvement in production processes. Each defect or complaint offers a chance to refine techniques and upgrade materials used in manufacturing.

| Mold Type | Material | Manufacturing Technique | Quality Control Method | Testing Process |

|---|---|---|---|---|

| Injection Mold | Aluminum | CNC Machining | Dimensional Inspection | Pressure Testing |

| Blow Mold | Steel | 3D Printing | Visual Inspection | Impact Testing |

| Compression Mold | Composite Materials | Press Molding | Functional Testing | Thermal Testing |