The automotive industry is rapidly evolving, driven by innovations in manufacturing processes and technologies. According to a report by MarketsandMarkets, the global automotive mold market is projected to reach USD 8.74 billion by 2025, with a significant portion attributed to advancements in Automotive Panel Mold solutions. These innovations not only enhance production efficiency but also improve the quality and design flexibility of automotive components. As manufacturers strive to meet increasing market demands and sustainability goals, the integration of digital technologies such as Industry 4.0, artificial intelligence, and additive manufacturing is transforming the landscape of automotive panel mold production.

This blog explores diverse examples of these groundbreaking innovations and their impact on global manufacturing, emphasizing how they are reshaping the future of the automotive sector.

The automotive industry is undergoing a dynamic transformation, significantly driven by innovative materials that are shaping the future of automotive panel molds. Traditional materials like steel and aluminum are increasingly being supplemented or replaced by advanced composites, thermoplastics, and bio-based materials. These alternatives not only reduce weight, enhancing vehicle efficiency but also provide better design flexibility and sustainability. For instance, thermoplastic materials can be easily molded and reshaped, allowing for rapid prototyping and reduced production times, which ultimately translates to cost savings.

Moreover, the incorporation of smart materials is revolutionizing panel mold designs, enabling features that were previously unimaginable. These materials can respond to environmental changes or mechanical stress, offering enhanced durability and functionality. Innovations such as self-healing plastics and lightweight foam cores are paving the way for stronger yet lighter automotive panels that meet stringent safety and environmental standards. As manufacturers embrace these advancements, we can expect a future where automotive panels are not only more efficient in production but also contribute to the overall performance and longevity of vehicles.

Sustainable manufacturing practices in automotive panel production are gaining significant traction as the industry turns towards greener solutions. A major challenge in achieving sustainability targets remains the lack of capital investment. This creates a barrier for many companies attempting to implement innovative manufacturing processes that meet environmental standards. However, advancements in flexible manufacturing systems are making it easier for manufacturers to adapt their production lines to accommodate various vehicle types, including internal combustion engines, hybrids, and fully electric models. This flexibility not only optimizes resource use but also reduces waste, which is crucial for sustainable operations.

Recent initiatives demonstrate a growing commitment within the automotive sector to prioritize eco-friendly practices. For instance, innovations in lightweight body structures using new-generation materials contribute significantly to lowering vehicles' overall environmental impact. Furthermore, leading players are establishing factories powered by renewable energy sources and employing advanced technologies for water reuse and carbon footprint reduction. These steps illustrate the industry's shift toward sustainable automotive panel production, promising a future where environmental stewardship is at the forefront of manufacturing practices.

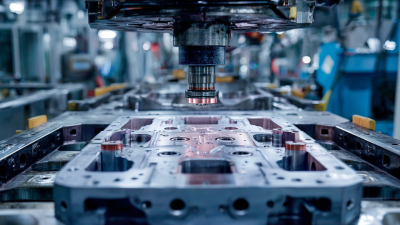

In the fast-paced world of automotive manufacturing, the integration of cutting-edge technologies has revolutionized mold design, enhancing efficiency and precision. Advanced techniques such as 3D printing and computer-aided design (CAD) have reshaped traditional methods, enabling manufacturers to create intricate mold geometries that were once deemed impossible. These innovations allow for rapid prototyping, drastically reducing lead times and allowing companies to respond more swiftly to market demands.

Moreover, smart technologies like the Internet of Things (IoT) and artificial intelligence (AI) are optimizing production processes by enabling real-time monitoring and predictive maintenance. IoT devices embedded within mold machinery provide crucial data analytics, allowing manufacturers to identify potential issues before they escalate into costly downtimes. AI algorithms enhance mold design by analyzing performance data to suggest improvements, thus ensuring that the molds remain at the forefront of efficiency and quality.

As these groundbreaking technologies continue to evolve, they are not just transforming the way automotive molds are designed and produced but are also setting new standards for global manufacturing practices. The marriage of innovation and manufacturing will undoubtedly lead to a future where efficiency and quality are paramount.

The global automotive industry is rapidly evolving, with a significant focus on the customization and integration of panel molds. As manufacturers strive to meet increasing consumer demands for personalization, innovative approaches to mold design and production have emerged. This trend is driven by advancements in materials and manufacturing technologies, allowing for more complex and tailored mold solutions. By leveraging techniques like additive manufacturing and simulation software, automotive companies can create molds that not only enhance vehicle aesthetics but also improve aerodynamics and fuel efficiency.

The global automotive industry is rapidly evolving, with a significant focus on the customization and integration of panel molds. As manufacturers strive to meet increasing consumer demands for personalization, innovative approaches to mold design and production have emerged. This trend is driven by advancements in materials and manufacturing technologies, allowing for more complex and tailored mold solutions. By leveraging techniques like additive manufacturing and simulation software, automotive companies can create molds that not only enhance vehicle aesthetics but also improve aerodynamics and fuel efficiency.

Moreover, sustainability has become a paramount consideration in the customization of automotive panel molds. Manufacturers are increasingly integrating eco-friendly materials and processes, reducing waste and lowering carbon footprints. This shift is not just beneficial for the environment; it also aligns with the preferences of modern consumers who are more environmentally conscious. The seamless integration of advanced technologies with sustainable practices positions automotive mold manufacturers to not only adapt to current market demands but also to lead the charge toward greener manufacturing solutions. As this dynamic market continues to grow, the drive for innovative automotive panel mold customization will redefine the standards of global manufacturing.

The automotive industry is rapidly evolving, and one of the most significant advancements in automotive manufacturing is the application of advanced simulation techniques in mold development. These technologies enable engineers to visualize and optimize the design of molds before physical production begins. By integrating simulation software into the workflow, manufacturers can predict potential issues such as material flow, temperature distribution, and stress points within the mold, reducing both time and costs associated with prototyping.

Moreover, these simulation techniques facilitate the exploration of diverse mold designs, enabling manufacturers to innovate and enhance productivity. With the capability to simulate various scenarios, engineers can refine designs for complex geometries and lightweight materials that are increasingly common in the automotive sector. This not only accelerates the development cycle but also ensures the production of high-quality automotive panels that meet stringent safety and performance standards. By embracing these advanced methodologies, manufacturers are well-equipped to adapt to the ever-changing demands of the global market, ultimately leading to more efficient automotive production lines.

| Mold Type | Material Used | Simulation Technique | Production Efficiency (%) | Cost Reduction (%) |

|---|---|---|---|---|

| Injection Mold | Steel | Finite Element Analysis | 30 | 15 |

| Compression Mold | Aluminum | Computational Fluid Dynamics | 25 | 10 |

| Blow Mold | Polypropylene | Moldflow Simulation | 28 | 12 |

| Rotational Mold | HDPE | Thermal Simulation | 20 | 8 |

| Die Cast Mold | Zinc Alloy | Dynamic Simulation | 35 | 18 |