In the automotive industry, the choice of materials can greatly impact a vehicle's performance. Automotive Panel Mold is a crucial component in manufacturing parts that must endure stress and environmental factors. Selecting the right mold can be complex. Quality and durability often clash with cost-effectiveness.

A strong Automotive Panel Mold ensures that panels can withstand the rigors of daily use. However, not every mold delivers the same benefits. Some may lack the sturdiness needed for high-performance vehicles. This inconsistency raises questions about manufacturing standards.

It's important to consider various options available for Automotive Panel Molds. While some may excel in longevity, they might not be ideal for every application. Reflections on performance versus durability are necessary. Balancing quality with economic factors can be challenging yet essential in production. The right choice can enhance safety while maintaining aesthetic appeal.

When considering automotive panel molds, the choice of materials significantly impacts quality and durability. Common materials include thermoplastics, steel, and aluminum. Each material has unique properties suitable for different applications. For example, thermoplastics like ABS are known for their lightweight nature and resistance to impact. They are often used in interior panels. Steel provides exceptional strength and durability but can increase the overall weight of the vehicle. Aluminum offers a balance of strength and lightweight characteristics, making it a popular choice for many manufacturers.

Research indicates that 80% of automotive manufacturers prioritize durability in their panel mold materials. A report from a leading industry analyst shows that the demand for lightweight materials is growing by 15% annually. This trend directly impacts fuel efficiency and performance. Many manufacturers aim for a perfect blend of weight reduction and structural integrity.

Tips: Regular testing of mold durability is crucial. Consider investing in advanced technology for accurate assessments. Also, keep in mind the environmental impact of your chosen materials. Opt for recyclable options when possible. Selecting the right material isn't just about cost. Reflect on performance over time and how it affects vehicle longevity.

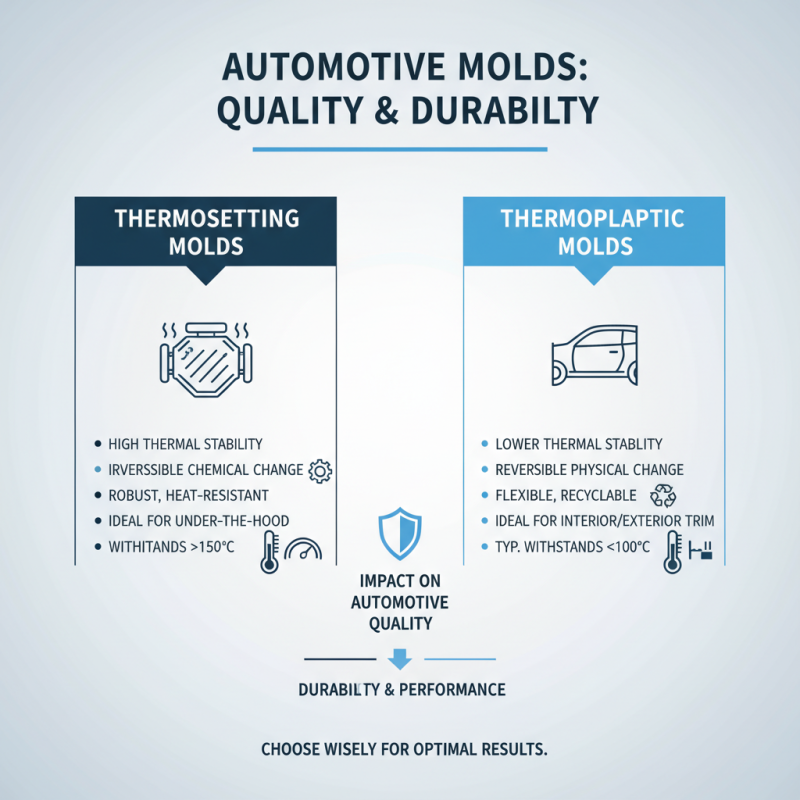

In automotive applications, choosing between thermosetting and thermoplastic molds significantly impacts quality and durability. Thermosetting molds, known for their high thermal stability, undergo a chemical change when heated. This process helps create robust and heat-resistant components, ideal for various automotive parts. According to industry reports, thermosetting materials can withstand temperatures exceeding 150 degrees Celsius, making them suitable for under-the-hood applications.

Conversely, thermoplastic molds offer flexibility and reusability. They can be easily molded, remolded, and reshaped without undergoing structural changes. This material is often favored for production runs with lower volumes due to its cost-effectiveness. However, thermoplastics typically do not perform as well under high heat, limiting their use in some automotive applications. Data suggests that thermoplastics account for approximately 35% of the automotive molding market, reflecting their popularity but also signaling possible performance trade-offs in specific environments.

Choosing the right mold type involves careful consideration of application requirements. While thermosetting molds excel in durability, they may present challenges in production time. In contrast, thermoplastics provide quick turnaround but face limitations in heat resistance. It's crucial to weigh these factors for optimal performance and longevity in automotive components.

The design of automotive molds plays a crucial role in the quality of panels. A well-crafted mold directly influences the surface finish, structural integrity, and overall performance of automotive components. According to a recent industry report, nearly 30% of panel failures can be traced back to poor mold design. It’s evident that the impact of mold precision cannot be overstated.

When considering mold designs, factors like temperature control and material selection are vital. Studies indicate that improper thermal regulation during the molding process can lead to warping. This can affect not just aesthetics but functionality as well. For instance, an inadequately designed mold might produce panels with inconsistent thickness, compromising strength. Manufacturers must recognize these pitfalls to improve longevity.

Mold efficiency also affects production costs and timelines. Inadequate design may cause delays due to frequent maintenance and adjustments. Interestingly, some reports suggest that investing in advanced mold technologies can reduce cycle times by up to 15%. Yet, many companies hesitate, fearing upfront costs. Balancing innovation with practical implementation remains a significant challenge in the automotive industry.

This chart illustrates the various factors impacting the quality and performance of automotive panels, measured by a quality score. High mold precision and material quality significantly contribute to overall panel durability.

Durability is critical in automotive mold production. The mold’s lifespan directly affects the final product's quality. Various industry reports highlight that nearly 40% of automotive components fail durability tests during production. Therefore, adhering to established testing standards is crucial for manufacturers.

Key standards to consider include ASTM D6000 and ISO 9001. ASTM D6000 focuses on materials' mechanical properties, ensuring they withstand stress. ISO 9001 emphasizes a consistent quality management system. These standards help in identifying potential weak points in molds early in the process.

Tips: Consider the environmental factors that affect durability. Temperature changes can weaken materials, leading to unexpected failures. Regularly review testing protocols to adapt to new technologies. Lastly, embrace continuous improvement methods for mold design. Each revision can yield better performance and reliability for automotive applications.

When analyzing costs for automotive panel molds, one must find a balance. High-quality materials often come with higher prices. However, cheaper options may lead to issues down the line. For instance, low-quality molds can cause defects in panels. These defects might require costly rework or replacements later.

It's essential to evaluate not just the initial cost but also the long-term value. Sometimes, investing more upfront can result in savings. Good-quality molds yield consistent results, reducing waste. On the other hand, chasing the lowest price can have hidden costs. They may lead to production delays or customer dissatisfaction.

Consider the life cycle of the mold. A well-made mold may last longer, producing more panels. It makes sense to weigh the upfront cost against potential future expenses. Quality molds often mean fewer defects and less downtime. Therefore, careful planning and a thoughtful budget approach are critical.