In the realm of manufacturing and construction, the choice of molds significantly impacts the efficiency and quality of production. Among various mold types, the Electric Box Mold stands out for its versatility and innovative design, making it an essential tool for numerous projects. According to a report by the International Plastics Engineering Association, the global demand for advanced molding technologies, including electric box molds, is projected to grow by 6.5% annually, driven by the increasing need for precise and reliable components in the electrical and electronic sectors.

The Electric Box Mold facilitates the creation of high-quality plastic enclosures for electrical junctions, switches, and other components. Its design allows for improved thermal management and minimizes warping and defects, consolidating its position within the industry. A recent study from the Association for Manufacturing Technology highlights that utilizing specialized molds like the Electric Box Mold can lead to production efficiency improvements of up to 30%. This statistic not only highlights the effectiveness of these molds but also underscores their importance in meeting the growing demands for customization and rapid production cycles in today’s competitive market.

As we explore the top benefits of using Electric Box Molds, it becomes evident that these molds not only enhance production efficiency but also contribute to sustainability initiatives by reducing material waste and energy consumption during the manufacturing process. The evolution of Electric Box Molds heralds a new era in mold technology, reflecting the industry’s commitment to innovation and excellence.

Electric box molds offer a multitude of advantages that can significantly enhance project efficiency in various applications. One of the primary benefits is the precision they bring to the manufacturing process. With electric box molds, the consistency in size and shape is greatly improved, which minimizes the need for extensive post-processing work. This level of accuracy not only saves time during production but also ensures that the final product meets specific requirements and standards.

Another advantage of using electric box molds is the speed at which projects can be completed. These molds are typically designed for rapid production, allowing manufacturers to achieve high output rates without compromising quality. The quick turnaround times help project managers adhere to tight deadlines, ultimately boosting productivity. Moreover, the ease of use associated with electric box molds can lead to reduced labor costs, as fewer operators are needed to run the machinery efficiently. By integrating electric box molds into their workflow, teams can experience streamlined operations and focus more on innovating and improving other aspects of their projects.

The advancement of electric box molds has significantly transformed the mold design industry, providing enhanced precision and accuracy that are essential for modern manufacturing. Research indicates that utilizing electric box molds can lead to a 20-30% reduction in production errors. This improved precision is largely due to the advanced technologies integrated into the mold-making process, such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies facilitate intricate designs that adhere to exact specifications, minimizing material waste and optimizing productivity.

One of the key benefits of using electric box molds is their ability to maintain consistent quality throughout the production run. Studies have shown that consistent temperature control during the molding process results in uniform material properties, which is critical for the performance of the final product. This level of accuracy not only meets customer expectations but also reduces rework costs and increases overall project efficiency.

Tips: When designing molds, it is essential to invest time in the initial planning phase to maximize the capabilities of electric molds. Ensure that all specifications are detailed, as this will facilitate smoother project execution. Additionally, regularly updating your software tools can enhance the precision of your designs, allowing for more innovative product development.

This chart illustrates the top ten benefits of using electric box molds in various projects, highlighting their effectiveness across different categories. Each benefit is scored based on a scale of 100, showcasing how electric box molds can enhance project outcomes significantly.

When it comes to constructing electric boxes, choosing the right mold can significantly impact the overall cost-effectiveness of your projects. Electric box molds are designed to optimize production processes while ensuring high-quality outputs. By using these specialized molds, manufacturers can reduce material waste and minimize labor costs associated with assembly and finishing. Additionally, the durability of electric box molds leads to longer production runs, which means fewer replacements and repairs, ultimately translating into savings.

Tips for maximizing cost-effectiveness include selecting molds that are compatible with your production machinery to avoid unnecessary alterations and maintenance expenses. Ensure a thorough assessment of production volumes before investing in molds, as this will help determine the most economical mold type for your needs. Furthermore, regularly maintaining your molds not only extends their lifespan but also keeps production costs in check by preventing costly downtimes.

By integrating electric box molds into your manufacturing process, you can achieve significant cost savings while maintaining quality. Remember to consider factors such as the initial investment, production efficiency, and long-term benefits when evaluating your options. This strategic approach will help you leverage the financial advantages of using electric box molds effectively.

| Benefit | Description | Cost Impact |

|---|---|---|

| Durability | Electric box molds are built to withstand repeated use and adverse conditions. | Reduces replacement costs. |

| Precision | Allows for consistent quality in production. | Minimizes waste and rework costs. |

| Customization | Molds can be tailored to specific project requirements. | Increases project efficiency and lowers custom fabricating costs. |

| Ease of Use | Design simplifies the molding process for users. | Saves labor costs. |

| Efficiency | Faster production times lead to quicker project completion. | Increases revenue potential through faster turnaround. |

| Reduced Material Costs | Less waste due to precision manufacturing. | Lower overall material expenses. |

| Versatility | Suitable for various applications in different sectors. | Maximizes tool utilization and reduces investment risk. |

| Maintenance Savings | Less frequent repairs needed on molds. | Lower maintenance costs over time. |

| Sustainability | Promotes use of recyclable materials in production. | Can lead to tax credits or lower compliance costs. |

| Increased Safety | Reduced risk of accidents and injuries on job sites. | Potential savings on insurance and liability costs. |

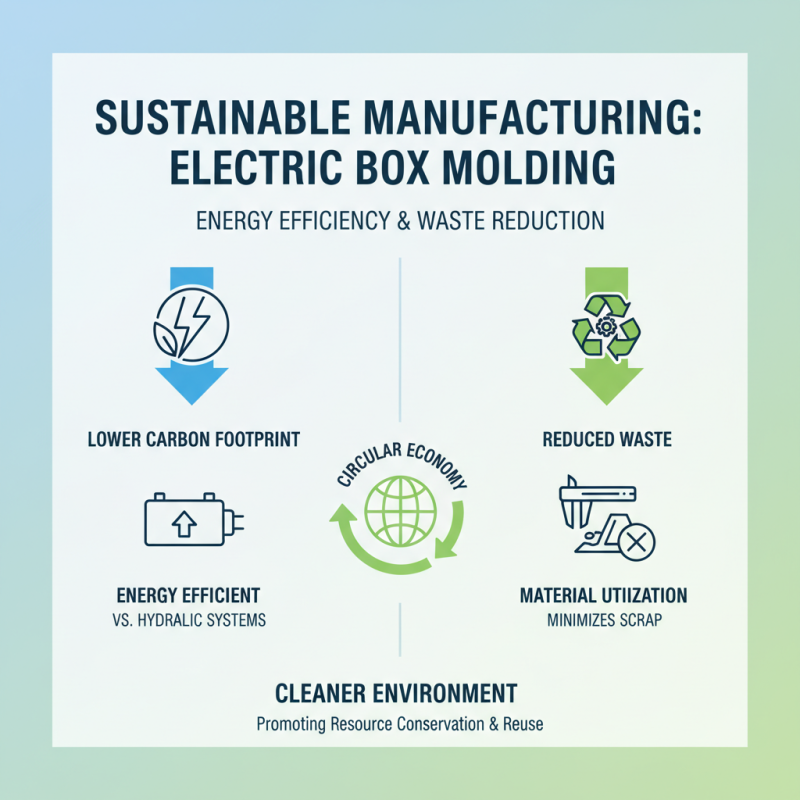

Electric box molding stands out as a sustainable option within manufacturing, primarily due to its energy efficiency and waste reduction capabilities. By utilizing electric molds, manufacturers can significantly decrease their carbon footprint compared to traditional hydraulic systems. The precision of electric molding also leads to better material utilization, minimizing scrap and waste during production. This shift not only contributes to a cleaner environment but promotes a circular economy where resources are conserved and reused effectively.

Tips: When considering electric box molds for your projects, aim to source materials that are recyclable or biodegradable, aligning your production processes with sustainable practices. Regular maintenance of your electric molding equipment can also enhance efficiency, further reducing energy consumption and operational waste.

Moreover, electric molding technology often employs cleaner processes that eliminate hazardous by-products associated with traditional molding methods. This results in a safer working environment for employees and communities alike. Adopting electric molding technologies not only meets industry standards for environmental responsibility but also appeals to consumers increasingly concerned about sustainability in products they purchase.

Tips: Evaluate the lifecycle impact of the materials you choose for your projects. Opt for suppliers who prioritize sustainable practices and can provide information on how their materials contribute to a lower environmental impact.

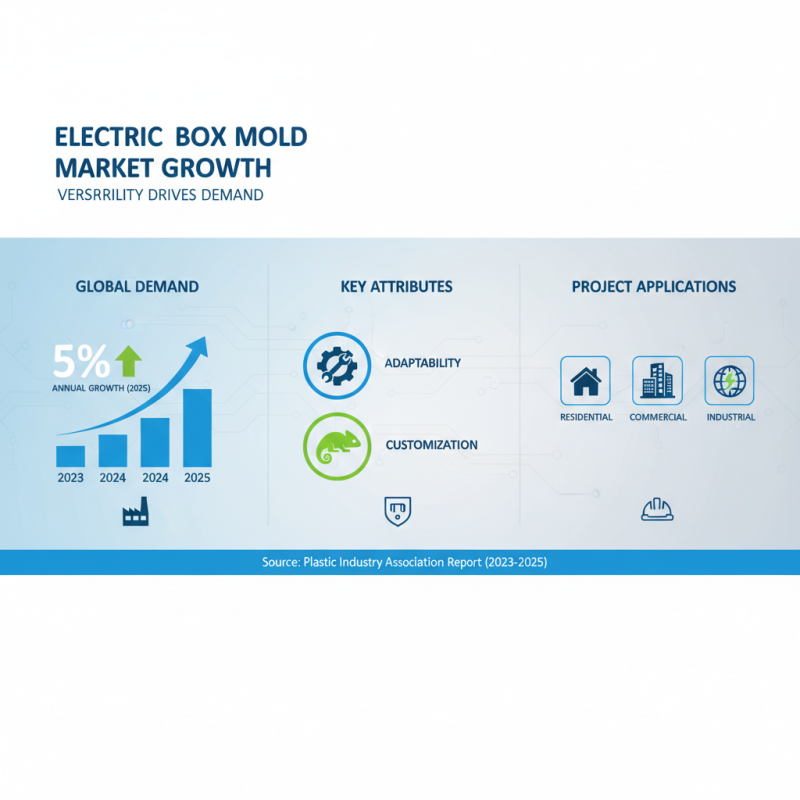

Electric box molds have gained substantial traction in the manufacturing and construction industries due to their impressive versatility and adaptability across various project applications. According to a recent report by the Plastic Industry Association, the demand for electrical enclosures and housing systems is projected to grow by 5% annually through 2025, reflecting the rising need for efficient and dependable electrical solutions. This growth underscores the ability of electric box molds to cater to a diverse range of project requirements, from residential infrastructure to large-scale commercial installations, offering custom solutions for different environments.

The adaptability of electric box molds also allows them to be utilized in various materials and finishes, accommodating projects that require specific properties such as weather resistance, thermal stability, or electrical insulation. For instance, research from the American Society of Mechanical Engineers highlights that utilizing engineered plastics in manufacturing these molds can significantly improve durability and longevity while reducing production costs by up to 20%. This makes electric box molds not only a practical choice for contractors and developers but also a cost-effective one, enabling them to efficiently meet project deadlines without compromising on quality or safety.