As we look ahead to 2026, the landscape of Advanced Mold Technology is evolving rapidly. Experts in the field are recognizing the potential of innovative techniques. John Smith, a leading figure in mold technology, once stated, "The future of manufacturing lies in smart mold innovations." This perspective underscores the significance of advancements in this sector.

New materials and processes are transforming how molds are designed and produced. Companies are focusing on creating molds that not only enhance efficiency but also reduce waste. For instance, 3D printing technology is becoming more prevalent, allowing for rapid prototypes and complex designs. This shift is a game-changer for industries relying on precise mold applications.

However, challenges remain. Many manufacturers struggle to keep pace with technological advancements. Adopting new techniques can be costly and time-consuming. As we advance, the need for training and adaptation becomes crucial. The evolution of Advanced Mold Technology may promise a brighter future, but it also demands thoughtful consideration of its implications on the industry.

In 2026, advanced mold technology is set to revolutionize various industries. Innovations in this field are driven by the need for efficiency and sustainability. Recent data shows that the global market for advanced molding reached $4.5 billion in 2025, with an annual growth rate of 7.2%. This trend highlights the importance of enhancing manufacturing processes.

A notable innovation is the use of biodegradable materials in mold making. These materials reduce environmental impact while maintaining performance. However, challenges remain in sourcing these materials efficiently. Industry reports suggest that only 30% of mold makers are currently utilizing sustainable practices. This indicates a significant gap in adoption that requires attention.

Moreover, smart technology integration is gaining traction. Incorporating IoT devices enables real-time monitoring and data analysis. This fosters predictive maintenance, reducing downtime. Still, the technology can be costly, making it inaccessible for smaller businesses. Reports indicate that in 2025, just 25% of small manufacturers leveraged smart mold technology, highlighting potential hurdles ahead. These innovations promise a more efficient future, but industries must address these challenges to fully realize their benefits.

The landscape of mold technology is evolving rapidly. One significant trend is the push for sustainability. Companies are looking to reduce their environmental footprint. This includes using eco-friendly materials and processes. Many manufacturers are experimenting with biodegradable plastics. These innovations are beneficial but come with challenges. Not all biodegradable materials perform well in diverse conditions.

Another trend is the rise of automation in mold production. Robotic systems enhance efficiency and precision. They minimize human error but require significant upfront investment. Adopting automation can be daunting for smaller businesses. As they strive to remain competitive, some may hesitate to make this leap.

In addition to these trends, data analytics is shaping mold technology. Analyzing production processes helps identify inefficiencies. Yet, reliance on data can be a double-edged sword. Not every company possesses the skills for advanced data interpretation. This gap can create disparities in the industry. Embracing these developments is crucial, but companies must reflect on their readiness to adapt.

This chart displays the adoption rates of key trends influencing the development of mold technology as of 2026. Innovations such as 3D printing and automation are significantly shaping the industry landscape.

Sustainable practices in advanced mold manufacturing are gaining momentum. As industries push for eco-friendly solutions, manufacturers are seeking innovative approaches. These include using biodegradable materials and energy-efficient technologies. By prioritizing sustainability, companies can reduce waste and lessen environmental impact.

One noticeable trend is the adoption of 3D printing in mold-making. This technique minimizes material use and cuts down on production time. However, challenges remain. Not all materials are suitable for 3D printing. Some traditional methods still offer better durability. Manufacturers must weigh the pros and cons carefully.

Recycling is another area worth exploring. Reusing scrap materials can lead to significant cost savings. Yet, the process isn’t always straightforward. It requires careful sorting and processing. Maintaining quality is crucial, and sometimes standards slip. Constant reflection and adaptation are necessary to ensure sustainability efforts succeed.

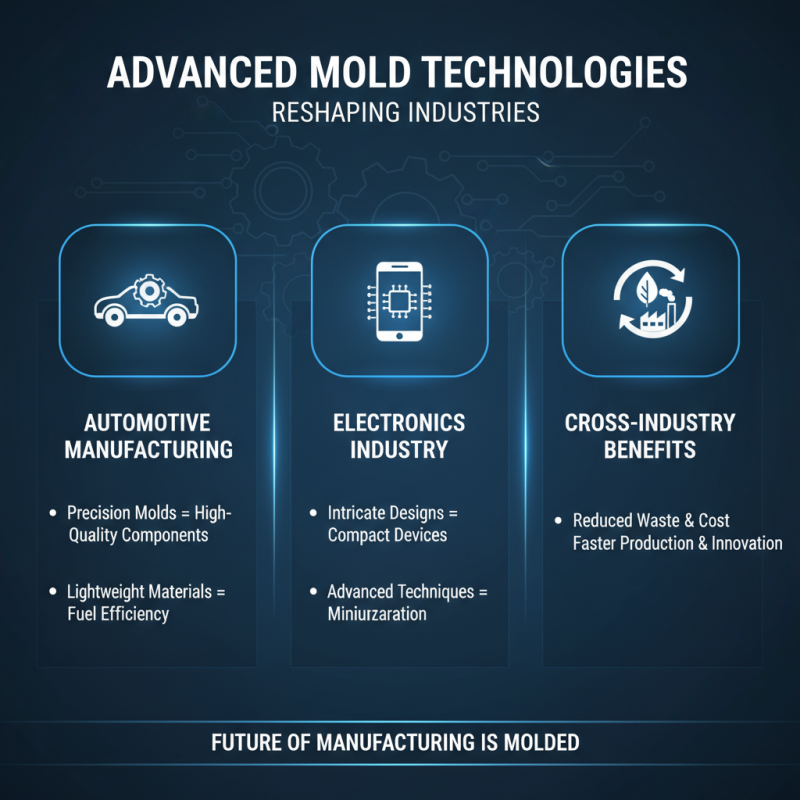

Advanced mold technologies are reshaping various industries. In automotive manufacturing, precision molds are critical. They ensure high-quality components with less waste. The use of lightweight materials improves fuel efficiency. This trend is also evident in electronics, where molds allow for intricate designs. Compact devices become possible with advanced molding techniques.

Tips: Focus on material selection. Using the right polymers can enhance durability. Experiment with different temperatures, as it affects the final product’s quality.

In the medical field, molds are crucial for creating custom devices. They enable tailored solutions for patients. Rapid prototyping speeds up the development process. Despite the advancements, challenges remain. Cost efficiency and scalability are often concerns. Reflection on these issues can lead to better strategies.

Tips: Keep testing prototypes. Small changes can yield significant improvements. Collaborating with experts enhances the overall design process.

Mold technology is evolving rapidly as we approach 2026. Innovations are sprouting up, and the future looks promising. Expect more automation in molding processes. This will reduce human error and increase efficiency. Smart sensors will play a key role. They will monitor conditions in real-time and adjust settings automatically.

Tips: Consider investing in training for your team. Understanding new technologies can boost productivity significantly. Regular workshops can help.

Moreover, sustainable practices are gaining traction. Eco-friendly materials are on the rise. As industries push for greener solutions, mold technology must adapt. Biodegradable resins could become mainstream. However, finding the right balance between sustainability and performance is challenging.

Tips: Always evaluate the trade-offs in material choices. Sometimes, less is more when it comes to innovation.

Looking beyond 2026, artificial intelligence could revolutionize mold design. AI can analyze vast datasets to improve product quality. Yet, this may bring complexities that need careful management. Be prepared for this shift in your operations.