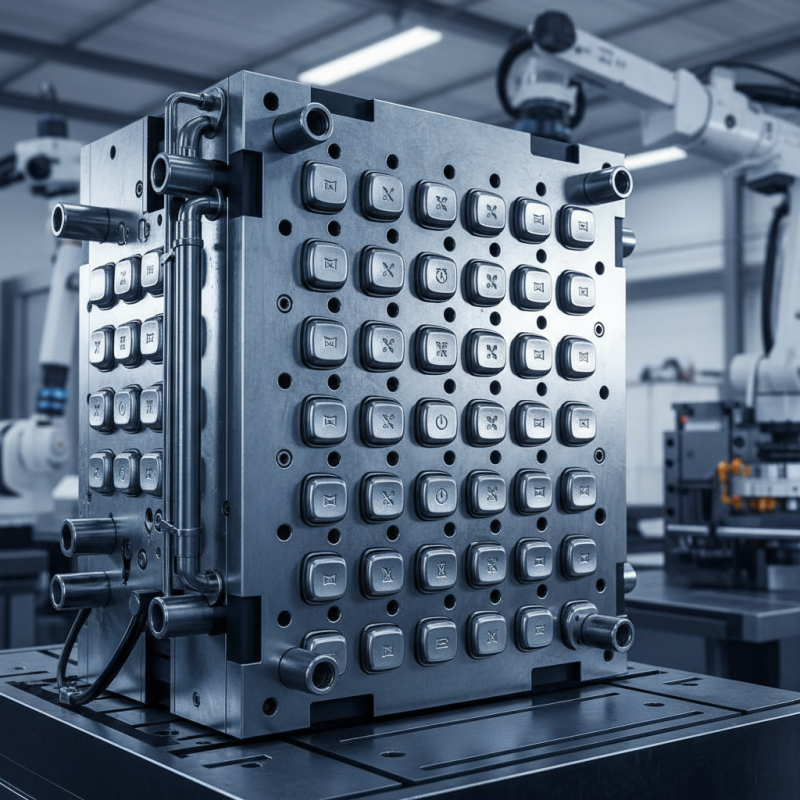

In the rapidly evolving automotive industry, the selection of the right Automotive Button Mold is critical for manufacturers aiming to enhance both efficiency and product quality. According to industry expert Dr. Emily Stratton, a leading authority on automotive manufacturing processes, “Choosing the right mold not only impacts the production timeline but also plays a vital role in the overall functionality and aesthetic appeal of the final product.” This insight emphasizes the significance of careful consideration in sourcing molds that meet specific production requirements.

As the demand for custom and innovative automotive components grows, understanding the intricate details of Automotive Button Mold selection becomes imperative. Manufacturers must evaluate factors such as material compatibility, mold design precision, and production scalability. By aligning their production needs with the most suitable mold options, companies can achieve a competitive edge in the marketplace while ensuring high-quality outputs that satisfy consumer expectations. Thus, the process of selecting an Automotive Button Mold should be approached with a strategic mindset, recognizing its profound impact on the entire manufacturing workflow.

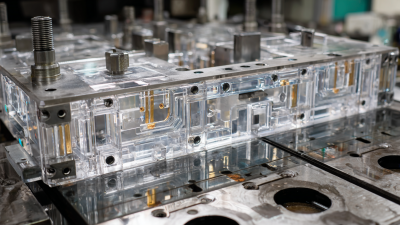

Automotive button molds play a crucial role in the production of various components in the automotive industry. These molds are designed to produce buttons that meet specific dimensions, aesthetics, and functional requirements. Understanding the basics of automotive button molds begins with familiarizing oneself with the types of materials used in their construction. Common materials include aluminum and steel, each offering distinct advantages in terms of durability, thermal conductivity, and cost-effectiveness. The choice of material can significantly impact the quality and performance of the finished product.

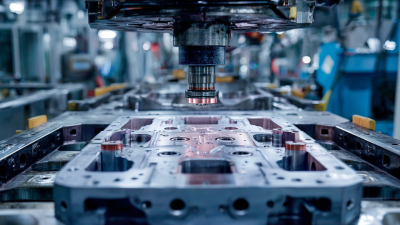

Another essential aspect is the design of the mold itself. A well-designed mold not only ensures precise shaping of the button but also facilitates efficient production processes. Factors such as cavity layout, cooling channels, and ejection systems are vital for optimizing production efficiency and reducing cycle time. Additionally, the design should accommodate potential variations in manufacturing, allowing for quick adjustments and repairs. By understanding these foundational elements, manufacturers can make informed decisions when selecting molds that align with their production needs, ultimately leading to enhanced product quality and operational efficiency.

When selecting the best automotive button mold, it's essential to consider several key factors that can significantly impact your production efficiency and product quality. One crucial element is the material selection for the mold. Different materials offer varying degrees of durability, thermal stability, and cost-efficiency. For instance, steel molds may provide longer lifespans and better precision for high-volume production, while aluminum molds could be advantageous for lower-volume runs due to their lower initial costs.

Another important factor is the design of the mold itself. A well-engineered mold can enhance the injection process and reduce cycle times. This is critical as industries, including automotive, strive for greater efficiency. According to market insights, the button mushroom cultivation market is projected to grow from $3.5 billion in 2024 to $5.2 billion by 2033, with a CAGR of 4.5%. This growth underscores the importance of efficient production strategies across various sectors, emphasizing the need for high-quality molds.

Tips: Always evaluate the mold manufacturer's experience and customer feedback to gauge reliability and support. Additionally, consider the technological capabilities of the mold, such as cooling systems and automated features, which can significantly optimize the production line. Lastly, don't overlook the importance of after-sales service and maintenance support, as they are vital for ensuring long-term operational success.

When selecting an automotive button mold, evaluating material options is crucial for meeting production needs. The choice of material not only influences the durability and functionality of the buttons but also affects the overall aesthetic and user experience. Common materials used include thermoplastics, silicone, and polyurethane, each offering distinct advantages. For instance, thermoplastics are favored for their lightweight properties and resistance to wear, making them ideal for high-production environments. In contrast, silicone provides superior elasticity and temperature resistance, which can be beneficial for buttons requiring a soft touch.

Additionally, the decision should consider factors such as the anticipated operational environment and user interaction. Materials should enhance tactile feedback while also being able to withstand exposure to harsh automotive conditions. Innovations in material science continue to expand the options available, with new blends and composites being developed to optimize performance. As automotive design evolves, staying informed about the latest material advancements will help manufacturers select the most suitable options for their specific application.

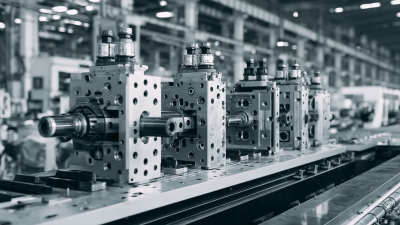

When selecting an automotive button mold, assessing production volume is crucial to ensure efficiency and cost-effectiveness. High production volumes may necessitate more robust molds designed to withstand the wear and tear of continuous operation. For manufacturers expecting to produce thousands or even millions of units, investing in a high-quality, durable mold becomes essential. It's important to evaluate the cycle time associated with the mold, as faster cycle times can significantly reduce overall production costs. Additionally, considering automation possibilities can enhance productivity, allowing for simultaneous operations that further meet volume demands.

Customization needs are another critical factor in the selection process. Automotive buttons often require specific designs, functionalities, and finishes that align with consumer preferences and brand identity. Custom molds can accommodate these specialized requirements, but they also come with increased design and production complexities. Manufacturers should balance the desire for customization with the practical aspects of maintaining efficiency in production. Partnering with a mold supplier that offers flexible design capabilities and rapid prototyping can help streamline this process, ensuring that the final product meets both design specifications and production timelines.

When selecting the best automotive button mold for production, cost analysis plays a critical role in balancing quality and budgetary constraints. Understanding the total cost of ownership, which includes initial tooling costs, maintenance, and expected lifespan of the mold, is essential. Manufacturers should consider both the short-term expenses and long-term investments to determine the most economical option for their specific production needs.

Additionally, evaluating the cost of materials used in the mold will significantly impact the overall budget. High-quality materials may incur higher upfront costs, but they often lead to improved durability and consistency in production runs. It is crucial to assess whether the enhanced performance justifies the additional expenditures. By conducting a thorough cost-benefit analysis, manufacturers can make informed decisions that align with their production requirements and financial objectives, ultimately ensuring the efficiency and competitiveness of their operations.