Choosing the right Automotive Die-Casting Molds can greatly impact production efficiency and product quality. These molds are essential for creating complex automotive parts. Their design must align with specific needs and requirements. A well-designed mold will ensure durability and precision. Yet, not all options are ideal for every situation.

Consider the details. Factors like material, cooling channels, and mold complexity play a role. Each element contributes to performance and longevity. Molds can be expensive. Investing wisely is crucial. Sometimes, a less costly option may yield better results in specific applications.

Reflect on past experiences. Not every selection has led to success. Learning from mistakes can help you choose more effectively in the future. Understanding the nuances of Automotive Die-Casting Molds allows for better decision-making. With careful consideration, the perfect mold can be found.

Die-casting molds play a crucial role in the automotive industry. These molds come in various types and materials, each offering unique advantages. Aluminum molds remain popular due to their lightweight and excellent thermal conductivity. According to a 2022 industry report, aluminum molds accounted for over 45% of the die-casting market. Meanwhile, magnesium molds are gaining traction due to their lower density and superior strength.

Understanding the different types of molds is essential. Cold chamber and hot chamber molds serve different functions. Cold chamber die-casting is preferred for high melting point metals. In contrast, hot chamber die-casting is suitable for metals with lower melting points. Choosing the right type can significantly impact production efficiency, a factor highlighted in the same report, which noted that choosing inappropriate molds could reduce production speed by up to 30%.

Material choices also matter. Steel molds, though costlier, are durable and resist wear over time. However, their initial investment is high, which might not always justify the cost for smaller runs. Industry data indicates that poor choices can lead to increased maintenance and slowing production lines. This dilemma requires careful consideration. Balancing cost and performance is key to making informed decisions.

Choosing the right automotive die-casting molds requires careful consideration.

One crucial factor is the material used for the molds. Different materials can affect durability and heat resistance. Steel molds, for example, offer longevity but might require a higher initial investment. In contrast, aluminum molds are lighter and easier to work with, yet they may wear out faster. Balancing cost and performance is essential.

Another important aspect is the mold design.

A well-designed mold can enhance the casting process and reduce defects. Pay attention to the intricacies of the design. Complex shapes may necessitate advanced techniques, which can increase production time and expenses. Don’t overlook how cooling channels are integrated; they directly impact cycle times and overall quality.

Consider the supplier's capabilities as well.

Not all manufacturers will have the same experience or technology to produce high-quality molds. It might be tempting to choose the lowest cost option, but think about the long-term implications. Poor-quality molds can lead to more defects and increased costs over time. Reflect on your specific needs and choose wisely.

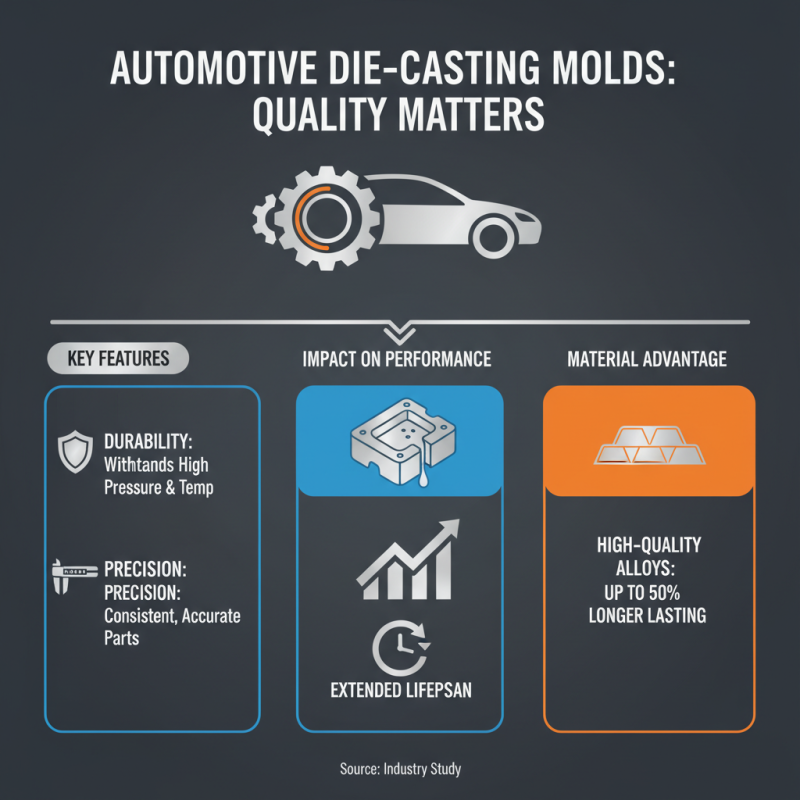

When choosing automotive die-casting molds, assessing mold quality is crucial. Key features significantly impact performance. Look for durability and precision. These characteristics ensure molds withstand high pressure and temperature. A study indicates that molds made from high-quality alloys can last up to 50% longer than standard options.

Another important aspect is the design complexity. Sophisticated designs may enhance performance. However, they can also lead to higher production costs. Consider your budget and specific needs carefully. Are you prepared for initial investments? A detailed cost-benefit analysis is essential.

Tips: Always check for surface finish quality. A rough surface can lead to defects. Don't ignore maintenance requirements either. Molds that require excessive upkeep might not be the best option. Engaging with experienced professionals during the selection process can save time and money in the long run.

When selecting automotive die-casting molds, balancing cost and quality is crucial. The alloy used in die-casting can impact both durability and functionality. High-quality molds made from premium materials may cost more initially. However, they often yield better results over time. A recent study indicates that poor-quality molds can increase production costs by up to 30% due to defects and rework.

Tip: Evaluate your production volume. Higher volumes often justify investing in better molds. This reduces the likelihood of defects and long-term costs.

Consider the specific requirements of your project. Each automotive component may demand different tolerances and material properties. Some molds may seem affordable but lead to higher scrap rates or longer lead times. Remember, a cheaper mold can lead to costly setbacks.

Tip: Perform thorough research on materials and designs. Invest in prototypes to test the molds before full-scale production. Quality assurance measures can save money in the long run. Evaluate all aspects carefully. Sometimes, the immediate savings are not worth the potential future costs.

| Mold Type | Material | Cost ($) | Quality Rating (1-10) | Lead Time (Weeks) |

|---|---|---|---|---|

| Low Pressure Die-Casting | Aluminum Alloy | 3,000 | 8 | 6 |

| High Pressure Die-Casting | Zinc Alloy | 5,000 | 9 | 4 |

| Sand Casting | Cast Iron | 2,000 | 7 | 8 |

| Investment Casting | Stainless Steel | 6,500 | 10 | 12 |

| Die Casting | Magnesium Alloy | 4,500 | 8 | 5 |

As we approach 2026, the automotive industry is witnessing significant changes in die-casting molds. These molds are essential for producing lightweight, durable parts. Recent reports indicate that the automotive die-casting market is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth is driven by the rising demand for electric vehicles and stringent regulations on emissions.

A shift towards advanced materials is evident. Aluminum and magnesium alloys are increasingly preferred due to their excellent strength-to-weight ratios. Industry data suggest that these materials enhance the energy efficiency of vehicles. However, the transition isn't without challenges. The sourcing of these materials may lead to increased costs and sustainability concerns. Furthermore, recycling and ensuring consistent quality remain pressing issues.

Technological advancements play a crucial role as well. Innovations such as 3D printing for mold design are emerging. These approaches can reduce lead times and waste. Yet, not all manufacturers have adapted to these technologies. Many still rely on traditional methods. This hesitance may hinder competitiveness in a rapidly evolving market. The need for skilled workers in adopting these advanced processes cannot be overlooked.