In the fast-paced automotive industry, choosing the right Automotive Connector Mold is crucial. The global automotive connectors market is projected to reach USD 29 billion by 2026, according to a recent report by MarketsandMarkets. This growth highlights the increasing complexity of vehicle electronics. Molds are vital in shaping reliable connectors that meet stringent quality standards.

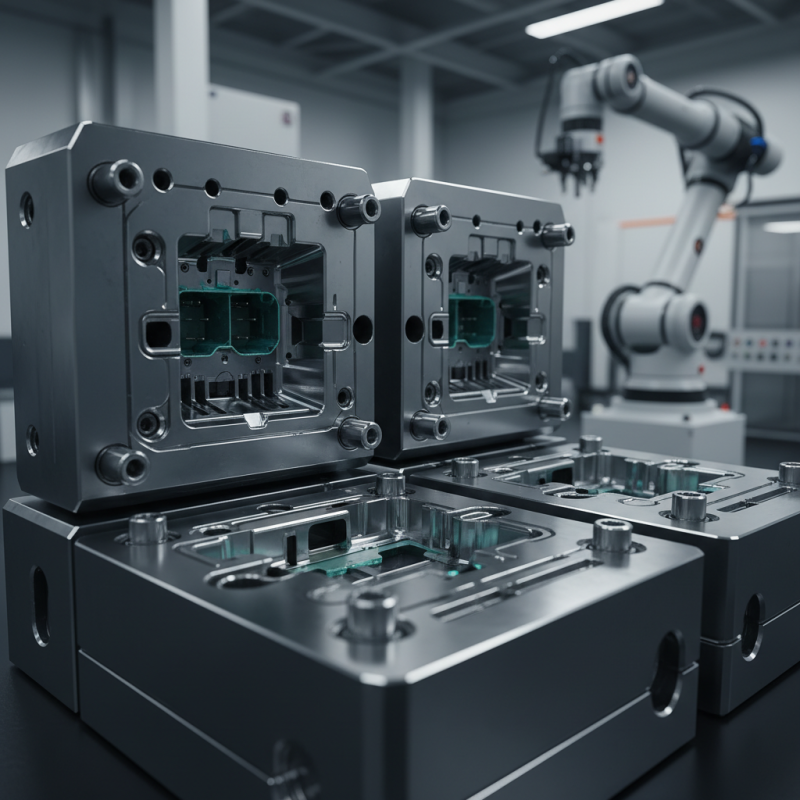

Automotive manufacturers face challenges in selecting the right mold. Factors such as material compatibility and design intricacies must be considered. For instance, using a high-precision mold can enhance connector performance, but it also demands a higher investment. Mistakes in this selection can lead to costly production delays and safety concerns. A reliable supplier is key to navigating this complex landscape.

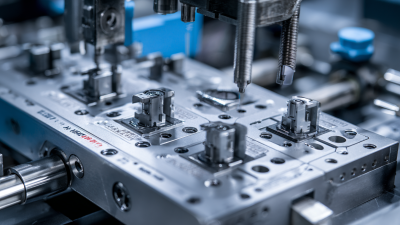

Understanding the impact of technology is essential. Advanced molding techniques, such as injection molding, can optimize production efficiency. However, not all molds are designed for the unique demands of automotive applications. This is where reflection on past choices can steer future decisions, ensuring that the selected Automotive Connector Mold aligns with industry advancements.

When selecting the right automotive connector mold, several key considerations stand out. Understanding the material used in the mold is crucial. Common options include thermoplastics and thermosets. Each has its unique properties that affect durability and temperature resistance. Assess the specific requirements of your project to make the best choice.

Tips: Consider production volume. High-volume needs often require different molds compared to low-volume projects. Think about the complexity of the design. Simple shapes are easier to produce than intricate ones.

Testing is vital. Prototype molds can help identify potential issues early.

Another important factor is the mold's design for ease of maintenance. Some molds may require frequent adjustments, leading to increased costs. Evaluate the ease of access to mold components. Poor accessibility can lead to longer downtimes. This can be a headache for production efficiency.

Tips: Collaborate with experienced designers. Their insights can save time and resources. Prepare for unexpected challenges. No project is without hurdles. Keeping an adaptable mindset is key. Consider all aspects thoroughly, and you’ll make informed decisions.

When selecting automotive connectors, understanding the types available is vital. Different connectors serve various functions, and their mold requirements vary significantly. For instance, standard connectors often require simpler molds, while high-performance connectors demand precision engineering. This is due to the need for durability and resistance to harsh conditions.

Tip: Assess the environmental conditions where the connectors will function. This will inform your choice.

Moreover, connector shapes can differ greatly. Some may need specialized features like locking mechanisms. Others could require additional sealing capabilities to protect against moisture and dirt. Understanding these specifications is crucial for effective mold design. Manufacturers must align mold creation with the specific connector’s performance attributes.

Tip: Collaborate with engineers to ensure the mold meets the specific needs of your connector type. This can save time and costs.

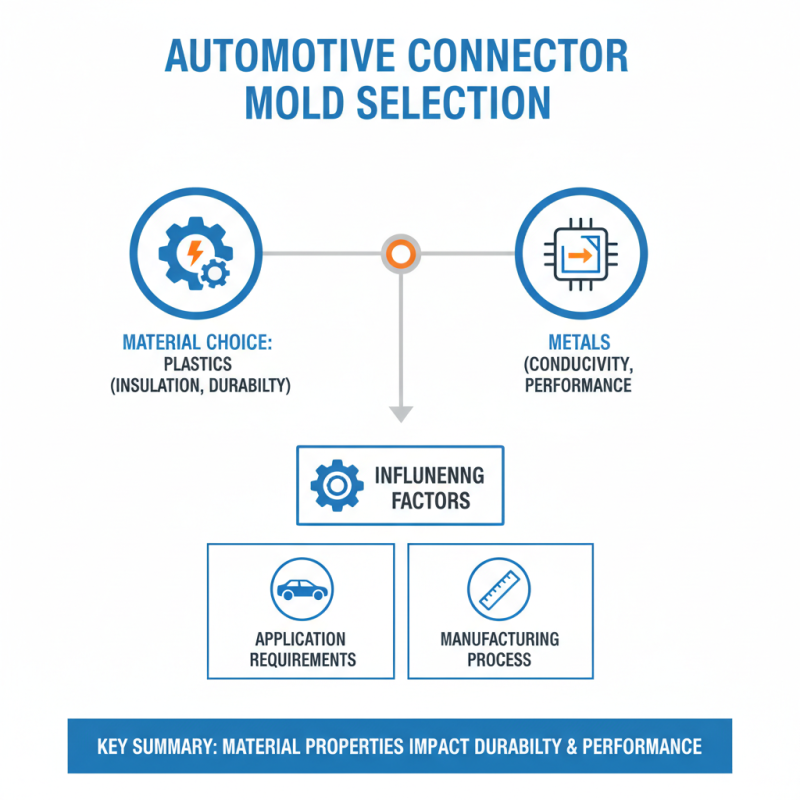

Consider also the material used for the connectors. Various plastics and metals have different melting points and cooling rates. This impacts the mold materials and design. Keep in mind, an ill-suited mold can lead to higher failure rates in the final products. Reflect on how well your chosen materials match your design requirements.

Choosing the right automotive connector mold can be challenging. Several factors influence this decision. First, you need to consider the material of the connectors. Different materials have unique properties. For example, plastics might offer insulation benefits, while metals provide better conductivity. This choice affects durability and performance.

Another critical factor is the application environment. Connectors in harsh conditions need to withstand temperature extremes and moisture. You may require molds that feature sealing options for added protection. The design of the connector also plays a crucial role. Complex shapes may need more precise molds, which can increase costs.

Additionally, production volume matters. High-volume runs allow for amortizing mold costs but may require rapid design changes. Sometimes a quick prototype is more efficient. Think about the long-term implications too. A cheap, quick solution isn’t always the best choice. Reflect on quality versus expense. Selecting the right mold needs careful thought and consideration.

When choosing an automotive connector mold, material compatibility is crucial. Different materials react uniquely under various conditions. This can affect the mold's lifespan and performance. For example, thermoplastics may offer flexibility but might not resist high temperatures well. In contrast, thermosetting plastics provide superior temperature resistance but can be more brittle.

**Tips:** Evaluate the environmental conditions where the connector will be used. Will it face extreme heat or moisture? Matching the right material to the function can prevent future issues. Compatibility also extends to the manufacturing process. Some materials may not mold well together, leading to defects and weak joints.

Testing is essential. Sometimes, materials that appear compatible might not perform as expected. Conduct trials before full production. Consider the entire lifecycle of the connector. A less durable material may mean more frequent replacements and higher long-term costs. Reflect on the decisions made during the selection process. Are they based on assumption or thorough research?

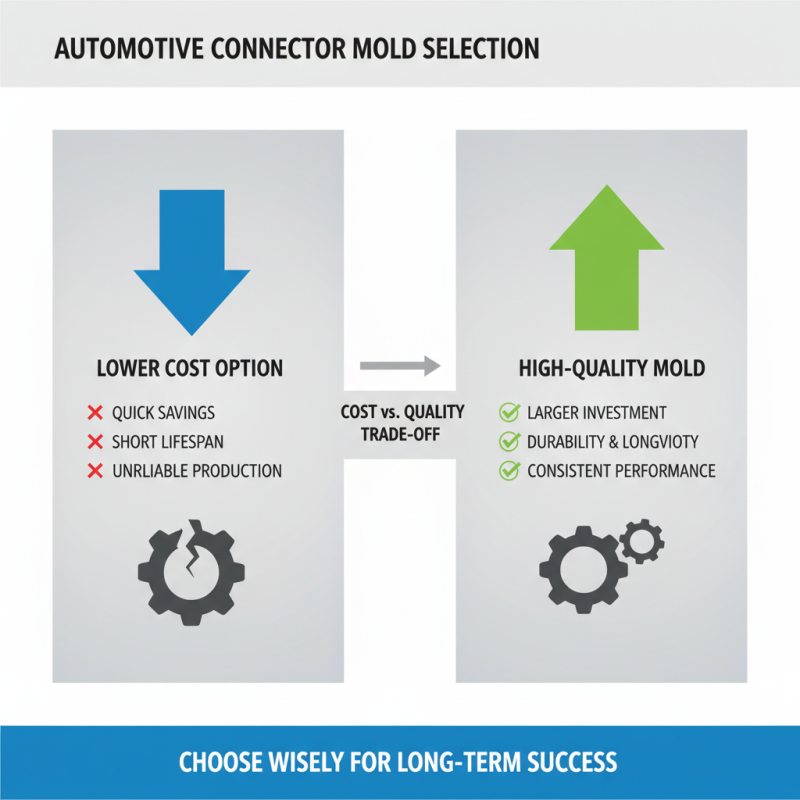

Choosing the right automotive connector mold requires careful consideration. Cost and quality are often in conflict. High-quality molds can be expensive, but they offer durability and reliability. A lower-cost option may seem attractive but could lead to issues later.

When deciding, think about the production volume. Large runs may justify a higher upfront cost. These molds provide better precision. However, for smaller projects, a budget-friendly option might suffice. Quality control should not be overlooked. Poor molds can lead to failures, resulting in costly recalls.

Reflect on the long-term impact of your choice. Sometimes, saving money initially leads to higher expenses down the road. Balancing these factors is crucial. Consider both immediate budget constraints and future reliability needs. Your goal should always be to select a mold that meets your project’s demands.