Choosing the right Automation Equipment Molds is crucial for efficient production. These molds significantly impact your workflow, quality, and costs. Companies face many options when selecting molds. Each choice carries unique benefits and challenges.

Understanding your specific needs is essential. Are you focusing on durability, precision, or perhaps speed? Molds should align with your production goals. Yet, the range of choices can be overwhelming. Some molds excel in one area but fall short in another. It's vital to assess these trade-offs carefully.

Additionally, don't overlook the importance of supplier reliability. A good supplier can provide insights into the best molds. They can also offer support during the selection process. Remember, the right mold can enhance productivity but a poor choice can lead to complications. Take the time for thorough research. The consequences of a hasty decision can be significant. Investing effort into this decision will pay off in the long run.

When selecting automation equipment molds, understanding their basics is crucial. These molds serve as the backbone for many automated processes. They create consistent parts quickly and efficiently. However, the right choice can be challenging.

Different projects require different molds. Material type, size, and complexity are essential factors. Selecting the wrong mold can lead to production delays. It's often easy to overlook specific details, leading to inefficiencies later. The mold must fit seamlessly into the automation system. A mismatch can result in wasted resources and time.

Consider the longevity of the mold. Some are designed for short runs, while others can handle long-term use. The initial choice might seem right, but wear and tear can reveal flaws. Regularly assess your production needs. Adaptability in mold selection is key. Automation is meant to simplify processes, but when the wrong mold is used, it complicates everything.

When selecting automation equipment molds, understanding your specific needs is crucial. Every production process is unique. Identifying the exact requirements will guide you toward the right mold. Consider factors like the type of materials you'll work with. Different materials need different mold designs. This can change the quality of the final product.

Think about the volume of production too. High-volume production requires durable molds. They should withstand constant use without wear. A well-designed mold can adapt to varied production runs. Assessing the speed of your processes is also essential. Fast production may necessitate a different mold type than slower processes.

It’s important to engage with your team when defining your needs. Input from operators can highlight potential issues. This can lead to better decisions about functionality. However, be ready to reflect on your choices. Sometimes, initial requirements evolve as the project progresses. Stay flexible to adjustments. This adaptability can lead to improved outcomes in the long run.

Choosing the right materials for mold production is vital for automation equipment. Material compatibility affects the durability and effectiveness of molds. Recent industry reports indicate that up to 30% of mold failures can be attributed to improper material selection. This highlights the importance of evaluating material properties carefully.

Different materials have distinct thermal and chemical resistances. For example, some polymers may degrade at elevated temperatures while metals could corrode under certain conditions. Understanding these limitations is key to maximizing mold lifespan. Manufacturers need to run compatibility tests before large-scale production. These tests can prevent costly errors, allowing teams to focus on efficiency and quality.

Companies often underestimate the impact of environmental factors. Humidity and temperature can affect material performance unpredictably. Ignoring these variables may lead to incomplete insights during the mold design process. Teams should consider these factors rigorously and seek continuous improvement in their material selection processes.

This chart illustrates the evaluation of material compatibility for different types of automation equipment molds. The data represents the compatibility ratings of various materials used in mold production, which is crucial for ensuring the longevity and effectiveness of the molds in different environments.

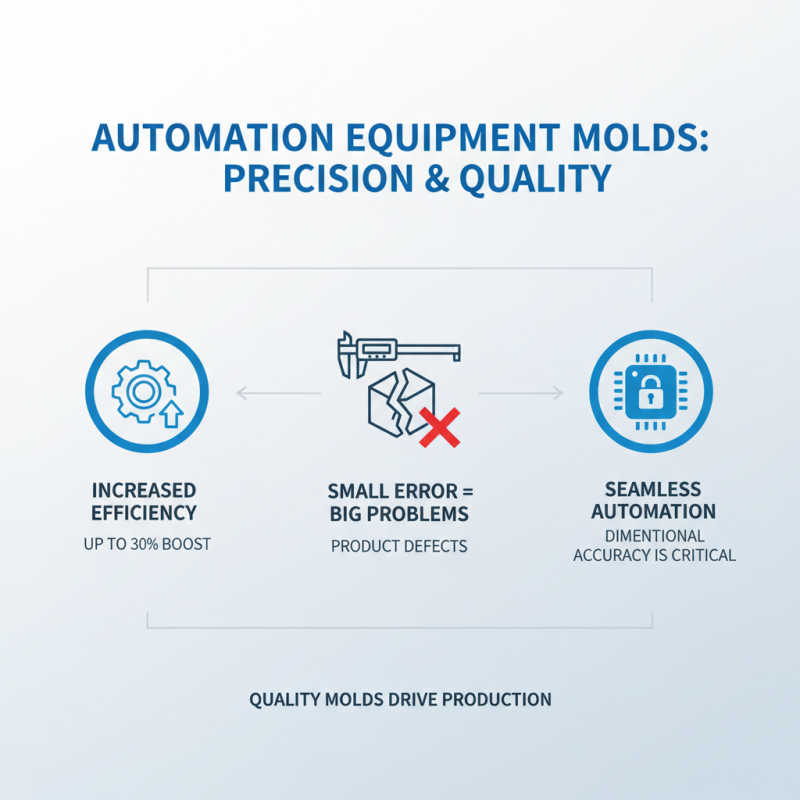

When selecting automation equipment molds, precision and quality are paramount. High-quality molds can boost production efficiency by up to 30%. A small error can lead to significant issues in mass production. For instance, inaccuracies in mold design may lead to product defects, impacting the final output. Precision in the mold's dimensions is critical for seamless automation.

Materials used for molds also play a vital role. Steel molds, while more expensive, offer durability and precision, often lasting five times longer than plastic alternatives. According to industry reports, investing in high-quality materials can reduce maintenance costs by 25% annually. However, not all manufacturers prioritize these aspects. Some opt for cheaper materials to cut costs, which can be a gamble in the long run.

Additional factors include mold design complexity. Intricate designs may allow for more innovative products but can complicate production. It's essential to strike a balance between design and manufacturability. Overly complex molds may lead to increased lead times and higher costs. Regularly evaluating these criteria helps ensure that production goals align with quality standards.

Choosing the right automation equipment molds requires a careful balance between cost and performance. According to a recent industry report, about 70% of manufacturers prioritize cost over quality. This approach often leads to increased maintenance expenses and lower production efficiency in the long run. While it may seem cheaper upfront, low-cost molds can significantly underperform, leading to higher rejection rates.

Performance is crucial. Molds that deliver consistently high-quality parts reduce waste and downtime. A study presented by the Society of Manufacturing Engineers shows that high-quality molds can improve production efficiency by as much as 30%. However, investing in these molds requires a larger initial outlay. It's a challenge to find molds that strike this balance. Companies must assess their specific production needs.

Additionally, not all molds exhibit the same durability. For instance, a standard steel mold might last 10,000 cycles, while advanced materials can endure up to 50,000 cycles. This discrepancy can affect overall productivity. It's vital to reflect on the long-term benefits against short-term costs. Skimping on quality often leads to unexpected frustrations and budget overruns. Factoring in maintenance and replacement costs is essential for making informed choices.

| Mold Type | Material | Cost (per unit) | Durability (cycles) | Lead Time (weeks) | Performance Rating (1-10) |

|---|---|---|---|---|---|

| Injection Mold | Steel | $5,000 | 500,000 | 8 | 9 |

| Blow Mold | Aluminum | $3,000 | 300,000 | 6 | 8 |

| Compression Mold | Plastic | $2,500 | 200,000 | 4 | 7 |

| Die Cast Mold | Zinc | $4,000 | 400,000 | 7 | 9 |

| 3D Printed Mold | Resin | $1,500 | 50,000 | 2 | 6 |