As the electric vehicle (EV) market continues to expand, the demand for high-quality Electric Vehicle Molds has surged. According to a recent market report, the global electric vehicle mold market is expected to grow at a CAGR of 15% over the next five years. This growth highlights the essential role that molds play in producing efficient and environmentally friendly vehicles. Prominent experts, including Dr. Emily Chen, a leader in automotive manufacturing, state, “The choice of Electric Vehicle Mold can significantly impact the production process and overall vehicle performance.”

Selecting the right Electric Vehicle Mold can be challenging. Factors such as material compatibility, design flexibility, and production volume must be carefully considered. Companies often face tough decisions that reflect their unique needs and capabilities. With varying levels of expertise and resources, not all manufacturers can achieve optimal results. Some may overlook the importance of specialized molds, leading to inefficiencies in production.

In a rapidly evolving industry, staying informed is crucial. The right Electric Vehicle Mold can enhance production efficiency and reduce costs. However, manufacturers must also be aware of potential pitfalls. An unsuitable mold might lead to defects or increased production time. Thus, a thoughtful approach is necessary to navigate these complexities and make informed choices.

When selecting the right electric vehicle mold, it's crucial to understand the different types and their functions. Mold types range from simple to complex. Each serves a specific purpose depending on the vehicle's design and requirements. For example, injection molds create precise components using high pressures. This method ensures accuracy but can be costly.

Compression molds, on the other hand, are easier to manage. They may produce less detailed parts but require less investment. Understanding these distinctions helps avoid costly mistakes. Consider your production needs and how many parts you require. If you only need a few, simpler molds may suffice.

Material choice also affects mold selection. Aluminum molds offer lightweight options, whereas steel molds tend to be more durable. However, the latter can take longer to produce, making project timelines a critical factor. Sometimes, it's necessary to weigh the benefits against budget constraints. Uncertainty can be frustrating, and mistakes will happen along the way. But with careful planning, you can find the right mold that fits your electric vehicle project.

This chart illustrates the various types of electric vehicle molds and their corresponding functions, showcasing the distribution of each mold type used in the manufacturing process.

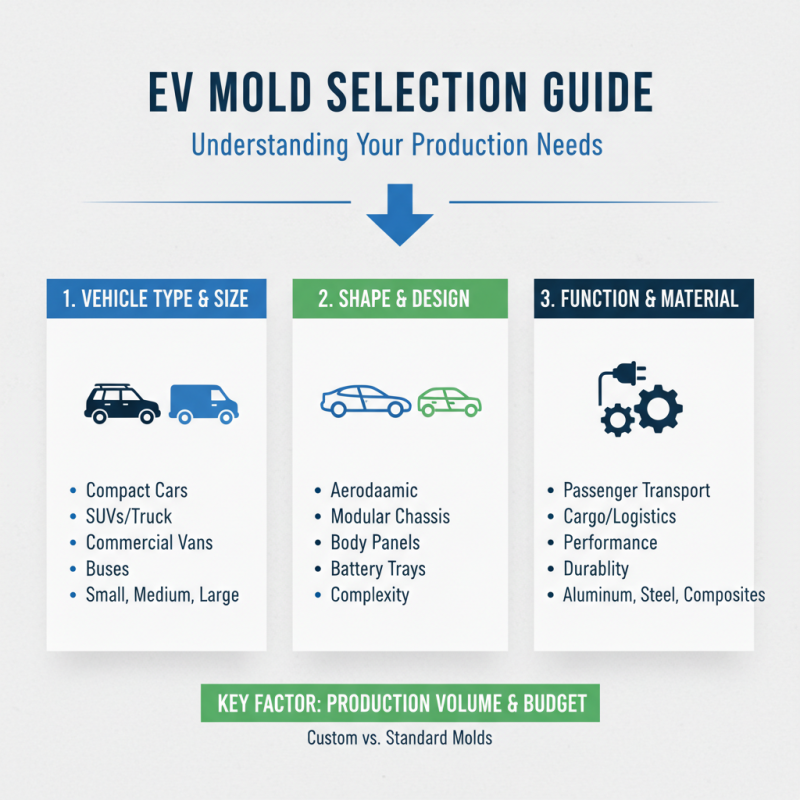

Choosing the right electric vehicle mold starts with understanding your specific production needs. What type of vehicle are you planning to produce? Consider the size, shape, and function of your electric vehicle. Each of these factors plays a role in mold selection.

When evaluating your requirements, think about the materials you will use. Will they be lightweight or more durable? This decision will influence the kind of mold needed. Assess the volume of production as well. A high-volume facility may require a different type of mold than a smaller workshop.

**Tips:** Consider consulting with experts in mold design. They can offer insights tailored to your needs. Also, don't forget to factor in maintenance costs. Molds need regular upkeep, which can add to the budget.

Be mindful that specific requirements may change over time. Flexibility can be crucial as technology evolves. It’s essential to keep an open mind during the selection process. Enhancements in electric vehicle design could mean adjusting your initial choices as you proceed.

When selecting materials for electric vehicle molds, consider their durability and weight. The right material influences efficiency and performance. Thermoplastics are popular due to their lightweight nature. They can withstand high temperatures and pressures, making them ideal for various applications. On the other hand, thermosetting plastics offer excellent thermal resistance and stability. They can be perfect for components that face extreme conditions.

Tips: Always evaluate the environmental impact of your chosen materials. Some options are more sustainable than others. Also, think about the long-term cost benefits. While some materials may have a higher upfront cost, they save money over time.

It's essential to reflect on the specific requirements of your project. Every vehicle part may need different properties. For instance, shock resistance is vital for certain molds. Remember, not every material will meet all needs. Balancing performance and cost can lead to tough decisions. A clear understanding of your product helps in making informed choices. Aim for a versatile approach that can adapt to changes in design and technology.

Choosing the right electric vehicle mold can be complex. Design intricacies play a crucial role in the selection process. Features like thickness, shape, and layering matter significantly. A mold must accommodate the vehicle's specific design. It should also ensure precision and efficiency in manufacturing. A slight miscalculation can lead to costly errors.

When considering mold selection, it's essential to think about the production volume. High volume may require different mold characteristics compared to low volume. Materials used in molds also affect durability and effectiveness. The cooling channels within a mold must be designed well. Poorly designed cooling can lead to defects. Reflecting on these aspects helps ensure optimal results.

Keep in mind that there is no "one size fits all" solution. Each electric vehicle project brings its own set of challenges. Sometimes, prototypes reveal unexpected issues. These moments are opportunities for reflection and improvement. Balancing design requirements and realistic capabilities is key. Make adjustments based on testing outcomes to achieve the best product.

| Dimension | Description | Considerations | Feature Importance |

|---|---|---|---|

| Material Type | Selection of aluminum, steel, or composite materials based on required strength and weight | Corrosion resistance, manufacturing process compatibility | High |

| Complexity of Design | Intricate shapes and features required for electric vehicle components | CAD modeling capabilities, manufacturing technology | Very High |

| Cooling Systems | Incorporation of cooling channels for temperature management of molds | Design efficiency, maintenance considerations | High |

| Production Volume | Molds designed based on anticipated production runs | Cost vs. benefit analysis for low vs. high volume | Medium |

| Repair and Maintenance | Ease of access for repairs or modifications to the mold | Long-term operational costs | High |

When considering the acquisition of electric vehicle molds, budgeting is crucial. The initial cost of molds can vary widely. Factors such as complexity and material impact the price significantly. Setting a budget helps narrow down options and prevents overspending.

Tips: Evaluate the total cost of ownership. Don't just focus on the upfront price. Consider maintenance and potential repair expenses. Research different materials before deciding. Some may be more cost-effective in the long run.

Additionally, it's vital to consider production volume. High volumes might justify investing in more advanced molds. Lower volumes could mean simpler molds suffice. This choice directly affects your budget. Analyze your production needs carefully.

Tips: Seek quotes from multiple suppliers. Prices can differ drastically. Establish clear specifications to avoid unexpected costs. Be prepared for additional fees, such as shipping and handling. Always leave room for adjustments in your budget.