The landscape of manufacturing is undergoing a significant transformation, driven in large part by the innovations in Electric Tool Mold technologies. As industries seek to enhance efficiency, reduce production costs, and maintain high-quality standards, Electric Tool Mold advancements are at the forefront of this evolution. These tools are not only integral to producing precision components but also play a crucial role in the development of more sustainable manufacturing processes. Recent trends indicate a shift towards automation and smart mold systems that leverage data analytics, which further streamline production workflows.

This introduction sets the stage for an in-depth exploration of how these innovations are reshaping the future of manufacturing, highlighting key insights and trends that are influencing the industry today. The impact of Electric Tool Mold innovations will be pivotal in addressing current challenges while paving the way for a more efficient and sustainable manufacturing landscape.

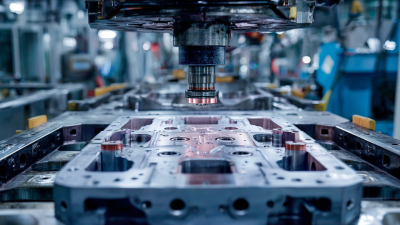

The advancement of electric tool mold innovations is significantly transforming the manufacturing landscape, particularly through the utilization of advanced materials. These materials, such as high-performance polymers and composites, offer enhanced thermal resistance and durability, making them ideal for high-volume production environments. By leveraging these sophisticated materials, manufacturers can produce molds that withstand increased wear and tear while maintaining precision and integrity throughout their lifecycle.

Moreover, the integration of innovative materials in electric tool molds leads to improved energy efficiency during the manufacturing process. Lightweight materials reduce the overall weight of the molds, facilitating faster cycle times and minimizing energy consumption during operations. Additionally, the use of materials with superior thermal conductivity ensures that heat is evenly distributed, reducing hotspots and extending the lifespan of the molds. These improvements not only streamline production but also contribute to sustainability initiatives by lowering the carbon footprint associated with manufacturing activities.

The rapid advancement of smart manufacturing technologies is significantly enhancing the performance of electric tool molds, leading to a new era of data-driven production. By integrating IoT sensors and artificial intelligence into the manufacturing process, companies can gather real-time data on tool mold performance, allowing for precise adjustments and optimizations. This data-driven approach not only increases efficiency but also minimizes downtime, as potential issues can be detected and addressed proactively.

Furthermore, the integration of smart technologies enables manufacturers to analyze production patterns and workflow dynamics more effectively. Predictive analytics plays a crucial role by forecasting maintenance needs and resource requirements, which can lead to more sustainable practices and reduced operational costs. As these tools evolve, the synergy between advanced technology and electric tool mold manufacturing will foster innovation, create competitive advantages, and ultimately shape the future landscape of efficient manufacturing.

The advent of 3D printing technology is revolutionizing the development of electric tool molds, significantly enhancing the efficiency of manufacturing processes. Traditionally, creating molds for electric tools involved long lead times and high costs due to the complexity of designs and the labor-intensive nature of the production. However, 3D printing allows manufacturers to rapidly produce high-quality prototypes and intricate mold designs, drastically reducing the time it takes to bring a product from concept to production.

Furthermore, the integration of additive manufacturing in mold development not only shortens lead times but also enables greater design flexibility. Engineers can easily modify mold designs in real-time, optimizing them for performance and functionality without the need for extensive retooling. This adaptability not only streamlines production but also fosters innovation, leading to the creation of more advanced electric tools that meet evolving market demands. As 3D printing continues to advance, its impact on electric tool mold development is expected to grow, paving the way for a more efficient and innovative manufacturing landscape.

| Dimension | Data |

|---|---|

| Average Lead Time Reduction | 30-50% |

| Adoption Rate of 3D Printing in Tool Molds | 75% |

| Cost Reduction in Mold Production | 20-40% |

| Percentage of Manufacturers Using Hybrid Processes | 60% |

| Increase in Design Flexibility | 85% |

| Future Projections for Market Growth | 15% CAGR by 2028 |

The electric tool mold industry is experiencing a significant shift towards sustainability, driven by a growing awareness of environmental impacts. Manufacturers are increasingly adopting practices that reduce waste and energy consumption throughout the production process. Innovations in mold design, such as the integration of lightweight materials and advanced manufacturing techniques, play a crucial role in minimizing raw material usage. These improvements not only enhance the efficiency of the molds but also contribute to lower energy demands during their production and operation.

Furthermore, the adoption of energy-efficient technologies is transforming how electric tool molds are created and utilized. For instance, utilizing renewable energy sources in manufacturing facilities helps to significantly lower carbon footprints. Additionally, the strategic use of recyclable materials in mold production supports a circular economy, where resources are reused and recycled, ultimately leading to a decrease in overall waste. As the industry continues to prioritize sustainability, these trends are expected to shape the future of electric tool molds, making them more efficient and environmentally friendly.

The future landscape of electric tool mold technologies appears promising with significant growth projections. The electric vehicle battery box market is expected to reach $2,533.07 million by 2024 and surge to $18,767.62 million by 2032, showcasing a robust CAGR of 29.7%. This trend indicates a growing demand for efficient manufacturing processes in tandem with advancements in electric tool mold innovations.

Moreover, the global automotive tool molds market is set to expand from $41.32 billion in 2024 to $60.88 billion by 2033, growing at a CAGR of approximately 4.4%. This growth is driven by technological advancements and increased investments in specialized steel and tooling solutions, further illustrating the necessity for manufacturers to adapt to these changes.

Tips: Consider exploring how automated processes in tool manufacturing can enhance efficiency and reduce lead times. Investing in innovative materials and technologies could also provide competitive advantages in this rapidly evolving market. Emphasizing sustainability in manufacturing practices will not only meet consumer demands but also strengthen your brand's image.