In the rapidly evolving landscape of modern industry, the adoption of Automation Equipment Molds has emerged as a critical driver of efficiency and productivity. According to a recent report by MarketsandMarkets, the global automation market is projected to reach $295 billion by 2025, highlighting a significant shift towards automated processes across various sectors. This trend is fueled by the need for enhanced precision, reduced production times, and lower operational costs, making automation equipment molds indispensable for manufacturers. These molds enable seamless integration of innovative technologies such as robotics, artificial intelligence, and data analytics, which are vital for staying competitive in an increasingly automated world. As industries strive for optimal performance and sustainability, understanding the five essential types of automation equipment molds can provide valuable insights into the transformation of manufacturing processes.

The rise of automation in manufacturing has dramatically shifted the dynamics of global industry. As companies strive for greater efficiency and productivity, the adoption of advanced automated equipment has become essential. This trend not only accelerates production processes but also enhances precision, reducing human error and operational costs. Industries ranging from automotive to electronics are leveraging automation to streamline workflows, resulting in shorter lead times and improved product quality.

Furthermore, the integration of innovative molds into automation systems is revolutionizing manufacturing landscapes. These molds are designed with smart technology that allows for real-time adjustments and monitoring, elevating the manufacturing standard to unprecedented heights. The ability to mold components seamlessly, while minimizing waste and maximizing resource utilization, speaks to the tremendous potential of automation in a sustainable future. As we witness this transformation, it is clear that the modernization of manufacturing through automation is not just a trend, but a fundamental shift that will define the industry's trajectory for years to come.

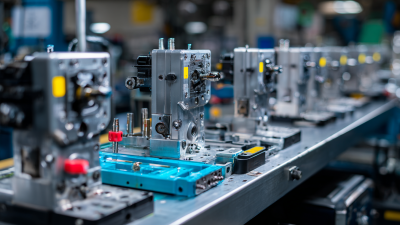

In the age of Industry 4.0, automation equipment molds are at the forefront of industrial innovation, serving as the backbone of modern manufacturing. These essential molds not only optimize production processes but also enhance precision and consistency in results. With smart technologies being integrated into machinery, businesses can achieve unprecedented efficiency, reducing waste and downtime substantially. The ability to adjust to various production needs quickly allows manufacturers to remain competitive in an ever-evolving market.

Tip: When choosing automation equipment molds for your operations, consider investing in flexible mold designs that can easily adapt to different products. This adaptability can save time and resources, enabling your facility to switch between production lines seamlessly.

Furthermore, the development of intelligent molds equipped with sensors and IoT capabilities allows for real-time monitoring and predictive maintenance. This technological advancement empowers manufacturing plants to proactively address issues before they lead to costly disruptions. As a result, businesses can optimize their supply chains and improve product quality simultaneously.

Tip: Incorporate data analytics tools to analyze the performance of your automation equipment molds. By understanding usage patterns and maintenance needs, you can make data-driven decisions that enhance productivity and longevity.

The landscape of modern industry is shifting dramatically with the integration of automation, particularly in molding processes. Automated molding not only enhances efficiency but also significantly reduces production costs. With machines that can operate continuously with minimal human intervention, companies are able to scale their operations without the typical overhead expenses associated with manual processes. This evolution in manufacturing emphasizes precision and consistency, leading to higher-quality products.

Tips for implementing automated molding systems include starting with thorough research to understand the specific needs of your production line. Assessing the type of materials used and the desired output can guide you in selecting the right equipment. Additionally, consider training programs for your staff to ensure they are well-versed in operating and maintaining these advanced systems, maximizing the return on investment.

Another important tip is to invest in predictive maintenance technologies that can foresee potential equipment failures. This proactive approach minimizes downtime and keeps production flowing smoothly. By prioritizing these strategies, businesses can harness the full potential of automated molding processes, driving both efficiency and cost-effectiveness in their operations.

| Mold Type | Material Used | Production Speed (units/hour) | Cost Reduction (%) | Impact on Waste Reduction (%) |

|---|---|---|---|---|

| Injection Molds | Thermoplastics | 1200 | 30 | 25 |

| Blow Molds | HDPE | 900 | 25 | 20 |

| Compression Molds | Rubber | 600 | 20 | 15 |

| Die Casting Molds | Aluminum | 800 | 35 | 22 |

| Thermoforming Molds | PVC | 750 | 28 | 18 |

In the rapidly evolving industrial landscape, automation equipment is proving to be a crucial element in shaping performance metrics through data-driven insights. As we approach 2024, emerging trends highlight the significant impact of technologies such as AI, IoT, and machine learning on operational efficiency. Reports indicate that businesses leveraging automation technologies can witness a reduction in operational costs by up to 30%, while simultaneously improving productivity by nearly 20%. This highlights the transformative role of automation in streamlining processes across various sectors.

Moreover, the integration of data analytics into decision-making processes is becoming paramount. A recent study emphasizes that companies utilizing data-driven decision support systems are able to optimize their planning and control mechanisms, leading to a 25% increase in project delivery efficiency. Such systems, often built on expert knowledge databases, empower organizations to make informed decisions, thereby enhancing overall performance metrics. As industries further embrace automation, the emphasis on data-driven insights will fundamentally reshape how performance is measured and improved in modern industrial practices.

As the future of automation continues to unfold, industrial equipment molds are set to play a pivotal role in transforming manufacturing processes. One of the most notable trends is the integration of smart technology into molds, facilitating real-time data collection and analysis. This advancement enables manufacturers to optimize production efficiency and reduce waste, ensuring that operations are not only cost-effective but also environmentally friendly. With the rise of the Internet of Things (IoT), molds equipped with sensors allow for predictive maintenance, minimizing downtime and enhancing productivity.

Another significant trend in industrial equipment molds is the shift towards customization and flexibility. Traditional molds often limit manufacturers to a one-size-fits-all approach, but the increasing demand for personalized products has prompted the development of modular molds. These adaptable molds can be easily reconfigured, allowing manufacturers to respond swiftly to changes in market demands. Furthermore, advancements in 3D printing technology are revolutionizing mold production, enabling rapid prototyping and reducing lead times. This evolution signifies a fundamental change in the industry, pushing boundaries and encouraging innovation in automation.