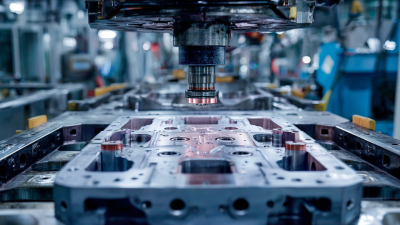

In the rapidly evolving landscape of the automotive industry, the significance of Automotive Parts Molds has never been more profound. As vehicles become increasingly sophisticated, the molds that shape their components must also evolve to meet rigorous performance and safety standards. Renowned expert Dr. Emily Carter, a leading figure in automotive manufacturing innovations, emphasizes the crucial role of advanced molding technologies:

"The future of Automotive Parts Molds lies in our ability to integrate smart design and advanced materials that not only enhance performance but also streamline production processes."

The convergence of digital technologies and manufacturing is reshaping how we approach mold design and production. Innovations such as 3D printing and computer-aided design (CAD) are enabling manufacturers to create more complex and efficient molds, leading to improved durability and reduced lead times. As Dr. Carter notes,

The convergence of digital technologies and manufacturing is reshaping how we approach mold design and production. Innovations such as 3D printing and computer-aided design (CAD) are enabling manufacturers to create more complex and efficient molds, leading to improved durability and reduced lead times. As Dr. Carter notes,

"Integrating digital solutions into the mold-making process will redefine how we produce automotive components, ultimately enhancing the overall vehicle performance."By exploring the future of Automotive Parts Molds, we can uncover the potential for enhanced performance, sustainability, and efficiency in the automotive sector. As we delve into the innovations that lie ahead, it becomes clear that the journey towards excellence in molding technology is not just a possibility but an imperative for the industry's future.

The automotive industry is on the brink of a transformative era, driven by innovations in automotive parts molds that promise enhanced performance and sustainability. A notable trend is the increasing adoption of nonwoven materials, which cater to the industry's demand for lighter and eco-friendly components. Reports indicate that this shift is not just a fleeting trend; it is part of a broader movement towards advanced materials that meet rigorous automotive standards while minimizing environmental impact.

Simultaneously, advancements in digital twin technology are reshaping the automotive landscape. By enabling manufacturers to simulate changes in production schedules and efficiencies associated with new car models, digital twins are enhancing the precision of manufacturing processes. According to market projections, the integration of these digital solutions is expected to significantly streamline operations, improving not only production timelines but also overall product quality.

Furthermore, the growth of the advanced packaging market, projected to reach USD 70.7 billion, highlights an increased focus on sustainable solutions across the automotive supply chain. Innovations in packaging are essential to reducing waste and optimizing logistics, further reinforcing the industry's commitment to sustainability. As the automotive parts mold segment evolves, these trends will be pivotal in shaping future production methodologies and enhancing vehicle performance.

The digital transformation sweeping through the automotive mold manufacturing industry is indeed a game changer. According to a report by McKinsey, companies that integrate advanced digital technologies into manufacturing processes can achieve productivity improvements of up to 30%. The adoption of smart manufacturing technologies, such as IoT and AI-driven analytics, enables manufacturers to optimize their operations, predict maintenance needs, and significantly reduce downtime. This shift is not just about automation but also about harnessing data to enhance decision-making processes.

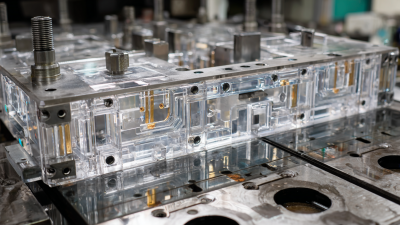

Incorporating digital tools can lead to more efficient designs, reducing the time it takes to create molds and allowing for rapid prototyping. A study from PwC highlights that early adopters of these technologies are not only increasing their output but also enhancing the quality of their products. For instance, improved simulation software allows engineers to test mold designs virtually, minimizing costly mistakes before they even occur.

**Tips:** To embrace digital transformation successfully, start by investing in training for your workforce to ensure they are equipped to handle new technologies. Additionally, consider forming partnerships with tech firms specializing in industrial solutions; this can accelerate your capability to innovate and respond to market demands. Lastly, regular assessments of your digital tools and processes can help identify areas for continuous improvement, maintaining your edge in a highly competitive landscape.

The automotive industry is undergoing a transformative phase, with innovative molding technologies playing a pivotal role in enhancing the performance of automotive parts. According to a report by MarketsandMarkets, the global automotive parts molds market is expected to reach $14.5 billion by 2026, growing at a CAGR of 4.1%. This growth is largely driven by the increasing demand for lightweight materials that improve fuel efficiency and reduce emissions, pushing manufacturers to adopt advanced molding processes such as injection and blow molding.

Key technologies shaping the future of automotive parts molds include 3D printing and advanced composite materials. A study by Smithers Pira indicates that the additive manufacturing market for automotive applications is projected to reach $3.5 billion by 2025, highlighting the industry's shift towards more flexible and cost-effective production methods. Moreover, the integration of smart technologies, such as IoT and AI, into mold production processes facilitates better design optimization and predictive maintenance. This not only strengthens the efficiency of the manufacturing cycle but also ensures higher precision and lower defect rates in final products, which are critical for meeting stringent automotive standards.

In the evolving landscape of automotive manufacturing, sustainability in mold design is becoming increasingly crucial. The India automotive plastics market is projected to reach a staggering US$ 4,210.8 billion by 2032, largely driven by the demand for lightweight materials that enhance vehicle performance while minimizing environmental impact. Innovations in automotive parts molds must prioritize materials that offer both efficiency and sustainability, reflecting a broader trend towards greener manufacturing processes.

Moreover, the integration of advanced materials such as high-performance polyamides is set to boost the industry significantly, with market estimates predicting growth from USD 2.08 billion in 2024 to USD 2.72 billion by 2029. This shift is indicative of an industry-wide commitment to balancing performance with environmental responsibility, emphasizing the importance of recyclability and circularity in manufacturing. As the automotive sector continues to embrace these advancements, the interplay between technological innovations and sustainable practices will be vital for achieving long-term success.

| Innovation Type | Material Used | Performance Enhancement | Sustainability Aspect | Impact on Cost |

|---|---|---|---|---|

| 3D Printed Molds | Polymer Composites | Increased Design Flexibility | Reduced Waste | Moderate Increase |

| Bio-Based Materials | PLA and Other Biopolymers | Enhanced Biodegradability | Lower Carbon Footprint | Higher Initial Costs |

| Smart Molds | Advanced Thermoplastics | Real-time Monitoring | Efficient Resource Use | Variable |

| Lightweight Alloys | Aluminum and Magnesium Alloys | Improved Fuel Efficiency | Recyclable Materials | Moderate |

| Nanotechnology | Nano-coatings | Enhanced Durability | Reduced Material Usage | Higher Production Costs |

In the rapidly evolving automotive industry, the integration of data analytics into mold production processes is revolutionizing the way manufacturers optimize efficiency and performance. By utilizing sophisticated data analysis techniques, companies can glean valuable insights from the vast amounts of information generated during the molding process. This enables them to identify inefficiencies, predict maintenance needs, and streamline operations, ultimately leading to a significant reduction in production time and costs.

Moreover, the adoption of predictive analytics allows manufacturers to simulate various molding scenarios, ensuring that the final design meets the high performance standards required in the automotive sector. By analyzing historical data related to mold performance and defects, teams can make informed decisions on material selection and process parameters. This proactive approach not only enhances the quality of automotive parts but also fosters innovation in mold design, creating opportunities for developing highly specialized molds tailored to evolving market demands. As the industry embraces these technological advancements, the future of automotive parts molds appears not only more efficient but also more responsive to the dynamic needs of the market.