In the rapidly evolving automotive industry, the demand for lightweight, durable components has led to an increased focus on sourcing high-quality Automotive Die-Casting Molds. According to industry reports, the global automotive die casting market is projected to reach $8.6 billion by 2025, growing at a CAGR of 6.2% from 2020. This growth is fueled by the rising need for efficient manufacturing processes that can produce parts with intricate designs at lower costs. As automakers strive to enhance vehicle performance and fuel efficiency while adhering to stringent regulatory standards, the quality of die-casting molds becomes paramount. Superior Automotive Die-Casting Molds not only ensure precision and durability but also significantly contribute to the overall success of high-volume production lines. This ultimate guide will provide insights into best practices for sourcing these critical components, focusing on key factors that influence mold performance and longevity.

Die casting has revolutionized the automotive industry by enabling manufacturers to produce complex parts with high precision and efficiency. There are several types of die casting processes, including hot chamber and cold chamber methods, each suitable for different application needs. According to a report by Grand View Research, the global die casting market size was valued at USD 12.33 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 5.5% from 2022 to 2030. This growth underscores the increasing reliance on die casting for producing lightweight, durable components.

When sourcing high-quality automotive die casting molds, it's important to consider the specific requirements of your production needs. For instance, aluminum die casting is favored for its lightweight and corrosion resistance, making it ideal for components such as engine blocks and transmission cases. On the other hand, zinc die casting is chosen for smaller, intricate parts like connectors and fasteners due to its excellent surface finish and dimensional accuracy.

Tip: When evaluating suppliers, request samples of previous projects to assess their capabilities. Additionally, consider suppliers that offer comprehensive post-processing services to further enhance the quality of the final product. It's vital to engage with manufacturers possessing expertise in the automotive sector to ensure the molds meet industry standards and specifications.

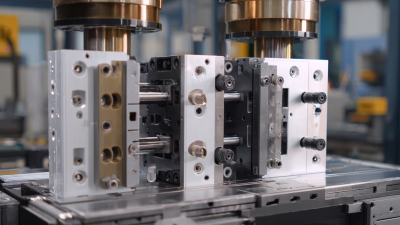

When selecting high-quality automotive die casting molds, several key factors come into play that can significantly impact the production process and final product quality.

First, the material of the mold is crucial. High-quality steel, often treated for durability, is preferred as it ensures longevity and minimizes wear over time, ultimately saving on replacement costs.

Additionally, the mold’s design needs to accommodate the specific requirements of the automotive components, including intricate shapes and tight tolerances that are essential in modern automotive engineering.

Another important consideration is the manufacturer’s experience and technology.

Advanced manufacturing techniques and expertise in die casting can lead to better precision and efficiency.

It’s vital to collaborate with suppliers who employ state-of-the-art equipment and methodologies, as this can enhance the overall performance of the molds.

Furthermore, post-production support and service attention should not be overlooked, ensuring any potential issues can be swiftly addressed to maintain production continuity.

In light of recent trends in the industry, such as new entrants pushing boundaries in design and production capabilities, these factors have never been more relevant as automakers strive to enhance their manufacturing processes to meet evolving market demands.

The selection of materials for automotive die casting molds significantly impacts their performance and longevity, especially in today's rapidly evolving automotive landscape. As electric vehicles become more mainstream, the need for molds that can withstand the thermal challenges posed by lithium-ion batteries is critical. High-quality materials not only improve mold durability but also play a crucial role in ensuring that components produced meet the stringent quality standards required for electric mobility.

Innovations in sustainable materials are equally relevant when sourcing automotive molds. The integration of advanced lightweight materials and composite materials can lead to more efficient production processes and enhance the overall performance of automotive components. For example, utilizing higher-strength alloys or advanced coatings can improve the thermal resistance and longevity of molds. By embracing these material advancements, manufacturers can better address the demands of modern automotive applications, ensuring optimal mold performance in the face of new challenges while also supporting sustainability goals in the industry.

When considering the investment in high-quality automotive die casting molds, conducting a cost-benefit analysis is paramount. The rapid expansion of the global casting and forging market, projected to grow from USD 187.38 billion in 2025 to USD 260 billion by 2033, underscores the importance of strategic investments in production capabilities. High-quality molds may require a higher initial investment, but they can lead to significant improvements in production efficiency, product quality, and overall output in the long run.

Moreover, as the metal casting market is expected to increase from USD 164.3 billion in 2024 to USD 247.4 billion by 2032, manufacturers must adapt to the growth and quality demands of the industry. Investing in durable and efficient die casting molds can not only streamline production processes but also enhance competitiveness in an ever-evolving market. As trends like megacasting gain traction, companies that prioritize high-quality tooling are likely to stay ahead of the competition, ensuring that their production capabilities align with current technological advances and market trends.

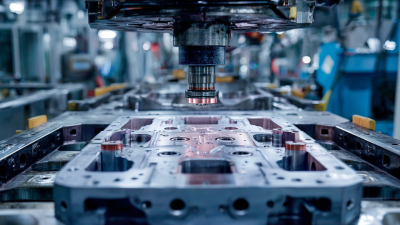

The automotive industry is currently experiencing a transformative shift fueled by emerging trends in die casting technology. Innovations such as the use of advanced alloys and the integration of automation in die casting processes are enhancing production efficiency and mold quality. Manufacturers are increasingly adopting these technologies to create more robust components that meet the evolving needs of modern vehicles, particularly as electric vehicles gain traction in the market.

Another significant trend is the focus on sustainability. The introduction of eco-friendly materials and processes reduces waste and energy consumption, aligning with global efforts to minimize environmental impact. Techniques like precision cooling and improved mold designs not only enhance product quality but also lead to lower energy usage during production. By leveraging these advancements, automotive manufacturers can produce lightweight yet durable parts that contribute to overall vehicle performance while adhering to sustainability goals.