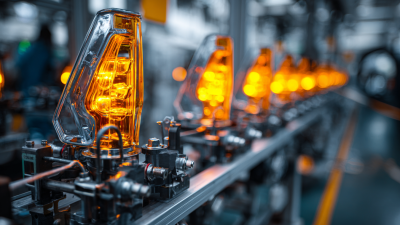

In the rapidly evolving landscape of modern manufacturing, the significance of Automotive Parts Molds has become increasingly pronounced. According to a recent report by MarketsandMarkets, the automotive mold market is projected to reach USD 43.46 billion by 2025, growing at a CAGR of 5.3% from 2020 to 2025. This growth underscores the critical role that high-quality molds play not only in enhancing production efficiency but also in ensuring the precision and quality of automotive components.

With the automotive industry embracing advanced technologies such as 3D printing and automation, adapting to these innovations while maintaining mold integrity is essential. This blog will delve into the importance of Automotive Parts Molds in modern manufacturing processes, offering tips and insights on optimizing mold design and production to meet the ever-increasing demand for quality and efficiency in the automotive sector.

In the realm of automotive manufacturing, the efficiency of production heavily relies on the quality and design of the molds used for creating automotive parts. Molds serve as the vital blueprint that shapes not only the function but also the performance of the final product. By investing in high-quality molds, manufacturers can streamline the production process, reducing both time and costs while improving part accuracy and durability.

**Tip:** When selecting molds, consider those made from high-grade materials like steel or aluminum, which offer greater longevity and can withstand the rigorous demands of high-volume production environments. Additionally, advanced mold design software can help optimize the mold configurations, leading to enhanced flow and reduced cycle times.

The role of molds extends beyond just shaping parts; they also contribute significantly to consistency and quality assurance. Well-designed molds minimize defects and variations, ensuring that each component meets stringent safety and performance standards. This reliability is crucial in the automotive industry, where even minor discrepancies can lead to severe consequences.

**Tip:** Regular maintenance and inspection of molds are essential practices to sustain their performance. Implementing a proactive maintenance schedule can preemptively address wear and tear, thereby prolonging the lifespan of the molds and maintaining overall production efficiency.

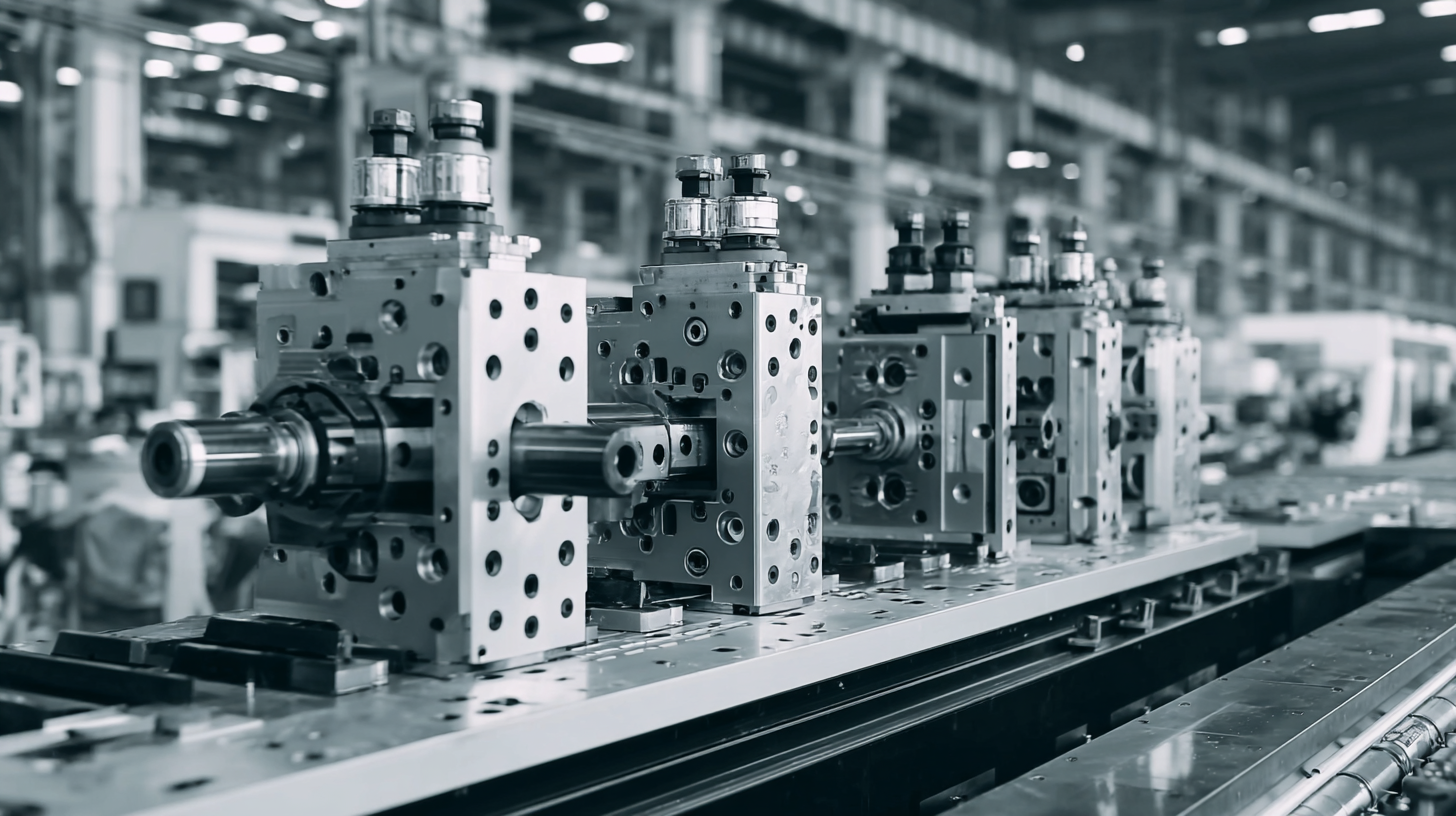

When it comes to automotive parts manufacturing, the significance of using high-quality molds cannot be overstated. The efficiency, precision, and durability of automotive components largely depend on the materials used in the molds. Key materials, each with distinct properties, play a crucial role in determining the performance and longevity of the molds. Steel is a favorite due to its strength and resistance to wear, making it ideal for high-volume production. Its ability to withstand high temperatures also ensures stability during the injection molding process.

In addition to steel, aluminum molds have gained popularity for their lightweight characteristics and faster heat dissipation. This not only accelerates the production process but also allows for more complex designs. Another emerging material is thermoplastics, which offer flexibility and ease of manufacturing. While they may not match the longevity of metal molds, their lower cost and quicker turnaround times make them an attractive option for certain projects. Choosing the right material for automotive parts molds is essential for optimizing production efficiency and ensuring the quality of the final products.

| Material Type | Common Uses | Advantages | Disadvantages |

|---|---|---|---|

| Steel | Engine components, structural parts | High strength, durability | Corrosion potential, heavier weight |

| Aluminum | Transmission housings, wheels | Lightweight, good thermal conductivity | Less strength than steel, more expensive |

| Plastics | Interior trim, bumpers | Corrosion resistance, flexible design | Less rigidity, potential for UV degradation |

| Composites | Body panels, reinforcement structures | High strength-to-weight ratio, design flexibility | Cost of production, complex manufacturing process |

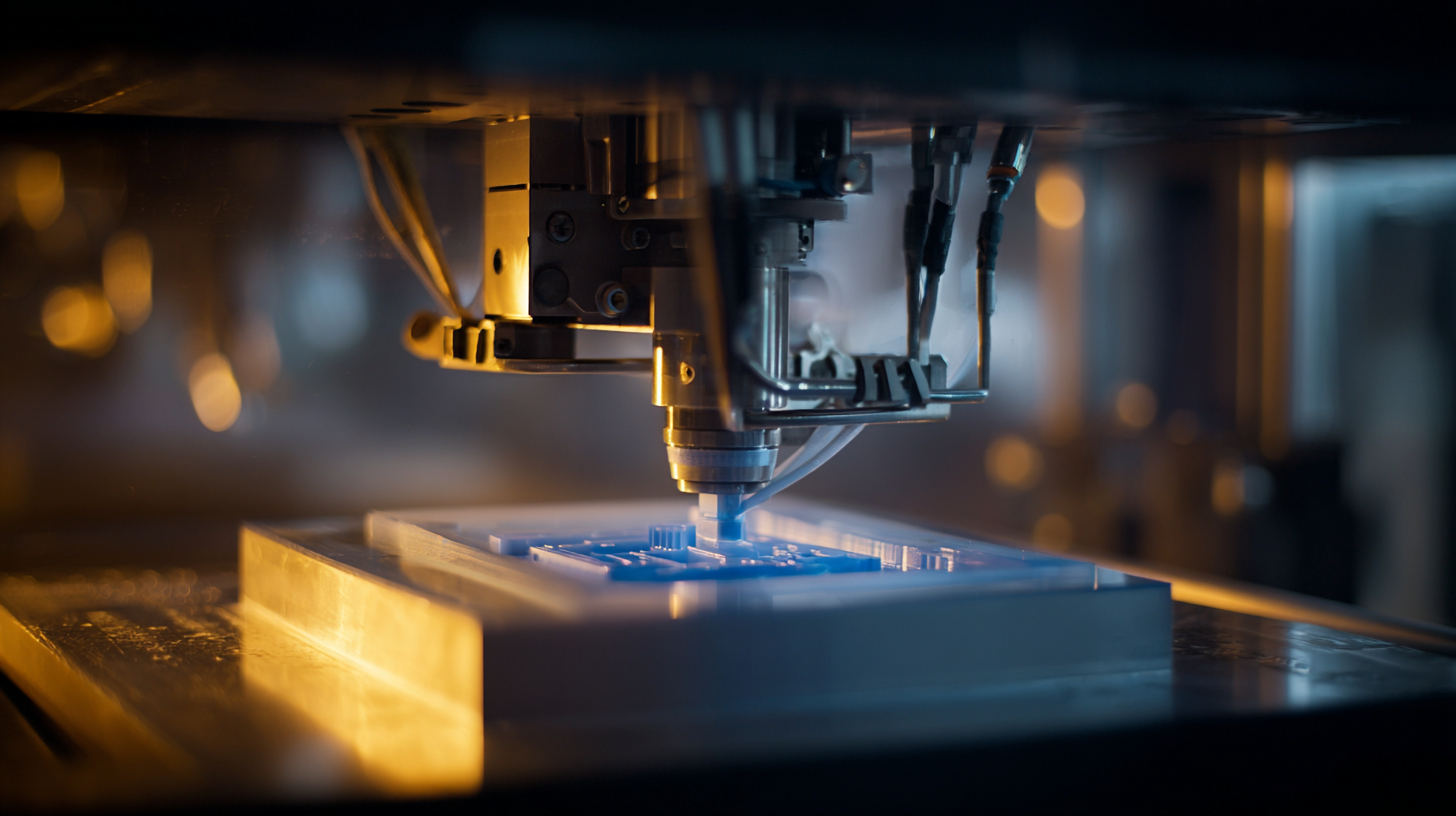

In the rapidly evolving automotive industry, innovative technologies are increasingly transforming the molding processes that are fundamental to manufacturing vehicle parts. These advancements are not only focused on enhancing efficiency but also on addressing the growing need for sustainability. For instance, the development of lightweight composite structures represents a significant shift towards materials that reduce vehicle weight, contributing to improved fuel efficiency and decreased emissions.

In the rapidly evolving automotive industry, innovative technologies are increasingly transforming the molding processes that are fundamental to manufacturing vehicle parts. These advancements are not only focused on enhancing efficiency but also on addressing the growing need for sustainability. For instance, the development of lightweight composite structures represents a significant shift towards materials that reduce vehicle weight, contributing to improved fuel efficiency and decreased emissions.

The integration of such lightweight materials into the manufacturing process underscores a commitment to environmental responsibility while still meeting the demands of modern vehicle performance.

Moreover, new techniques in in-mold coating technology are revolutionizing the way automotive parts are finished. By combining the processes of molding and painting into a single step, manufacturers can streamline production, reduce waste, and minimize the environmental footprint of their operations. These innovations exemplify how the automotive sector is leveraging cutting-edge technologies to align with sustainable development goals, creating a future where efficiency and eco-friendliness coexist within the manufacturing landscape. As the industry continues to evolve, the importance of automotive parts molds equipped with these advanced technologies cannot be overstated.

In the realm of modern manufacturing processes, the significance of quality control and testing for automotive parts molds cannot be overstated. As automotive industries increasingly focus on sustainability, the recycling of plastic auto parts is gaining attention, highlighting the need for rigorous quality assurance testing to ensure the performance and reliability of recycled materials. Effective testing methods are essential to maintain the industry standards, especially as recycled resins often exhibit variability compared to prime materials.

Manufacturers must invest in advanced metrology services and testing techniques that provide precise data, ensuring that every component meets stringent safety and performance criteria.

Moreover, innovations in mold service technology, such as tool separators that streamline the maintenance process, also play a crucial role in quality assurance. By minimizing downtime during mold servicing, these tools enhance the efficiency of the testing phase, leading to faster product development cycles without compromising quality. This synergy between rapid mold maintenance and thorough testing practices paves the way for the integration of in-mold assembly techniques and the use of all-electric machinery, further emphasizing the industry’s commitment to

quality and sustainability.

The automotive manufacturing industry is on the brink of a significant transformation, driven by key trends in sustainability and automation, particularly in the realm of parts molding. As the focus shifts towards eco-friendly materials, polymers such as polyethylene (PE) and polypropylene (PP) are becoming increasingly popular due to their lightweight properties, cost-effectiveness, and recyclability. These materials can be easily manipulated through various processes like injection molding and blow molding, which optimize production efficiency while minimizing waste—a crucial aspect of sustainable manufacturing.

In addition to material advancements, the adoption of automation technologies in automotive parts molding is reshaping the manufacturing landscape. Automated systems enhance precision and speed, addressing labor shortages and reducing production costs. Liquid Injection Molding (LIM) and Liquid Silicone Rubber (LSR) are becoming vital in this transition, catering to higher demands for complex and durable automotive components. The expected growth in the LIM and LSR markets, from $148.41 million in 2023 to $159.5 million in 2024, underscores the increasing reliance on advanced manufacturing techniques that are not only efficient but also environmentally conscious. These combined efforts pave the way for a more sustainable and automated future in automotive manufacturing.