The automotive industry is experiencing a paradigm shift, driven by advancements in manufacturing technologies and increasing demand for efficiency. According to a report by Allied Market Research, the global automotive parts molds market is projected to reach $11.5 billion by 2027, growing at a CAGR of 5.8% from 2020. This growth underscores the necessity for innovative strategies to optimize the production efficiency of automotive parts molds, which are integral to the manufacturing of critical components. By implementing cutting-edge techniques such as additive manufacturing, real-time data analytics, and lean manufacturing principles, companies can significantly reduce lead times, minimize waste, and enhance overall productivity. As the industry continues to embrace automation and smart manufacturing, understanding and applying these innovative strategies will be crucial for staying competitive and meeting the evolving demands of the market.

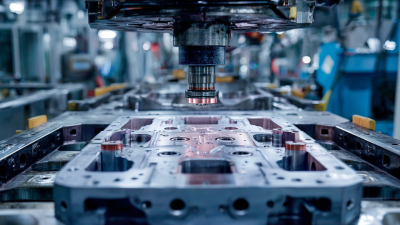

The automotive industry is evolving rapidly, with innovative technologies transforming the landscape of parts mold design. Advanced simulation software, for instance, is enabling engineers to visualize the injection molding process and predict potential defects before production begins. According to a report by the Plastics Industry Association, utilizing simulation tools can reduce mold design time by up to 30%, leading to even faster time-to-market for new automotive components.

Tips: When designing molds, consider adopting generative design technologies, which leverage AI to create optimized shapes and structures that minimize material usage and maximize strength. This approach not only enhances production efficiency but also contributes to sustainable practices—an essential factor in modern automotive manufacturing.

Another significant innovation is the incorporation of 3D printing in mold production, which allows for rapid prototyping and iterative improvements. A study from the Society of Manufacturing Engineers highlights that 3D printing can cut mold development time by up to 50%, greatly enhancing overall productivity. As these technologies advance, they pave the way for a more agile and responsive automotive parts production process, catering to the increasing demand for customized solutions.

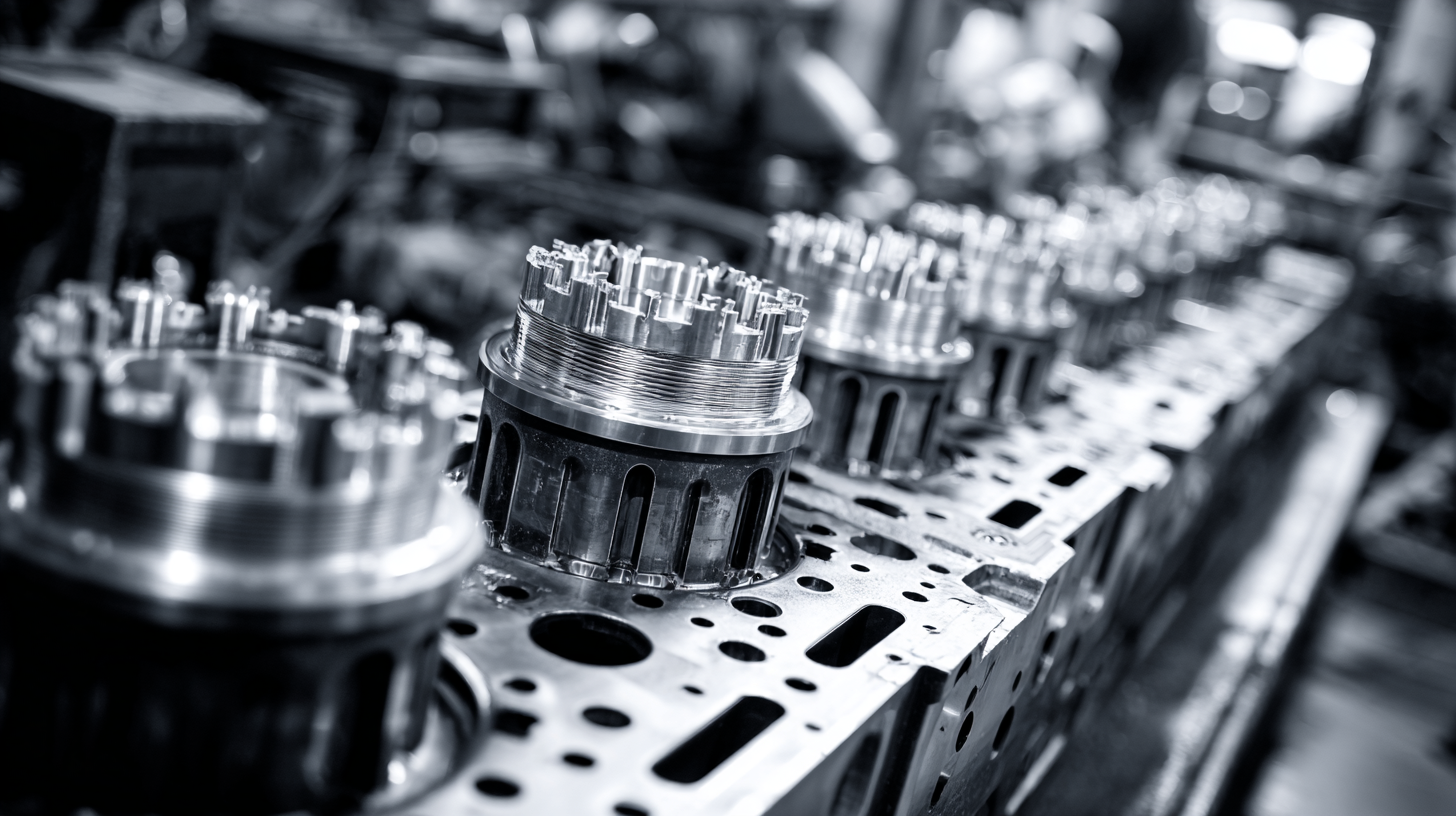

In the pursuit of enhanced efficiency in automotive parts mold production, automation techniques play a pivotal role. The integration of advanced robotics and machine learning algorithms into the production line allows for real-time monitoring and adjustment of processes, resulting in reduced cycle times and improved product consistency. Automated systems can handle repetitive tasks, such as material loading and unloading, with precision and speed, minimizing human error and allowing operators to focus on more strategic tasks.

Furthermore, the implementation of Industry 4.0 principles enables manufacturers to leverage data analytics for predictive maintenance and inventory management. Sensors embedded in machinery provide continuous feedback, which helps in anticipating potential equipment failures before they occur and optimizing maintenance schedules. This proactive approach not only curtails downtime but also ensures that production lines operate at peak performance. By streamlining these processes, automotive manufacturers can significantly enhance their production capabilities and respond more agilely to market demands.

This bar chart demonstrates the production efficiency of automotive parts molds across various automation techniques, illustrating the impact of each strategy on the overall efficiency.

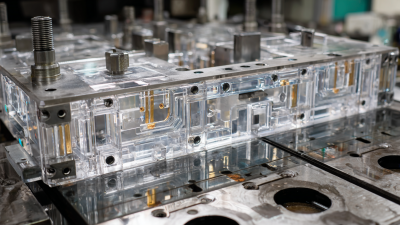

The optimization of automotive parts molds production efficiency heavily relies on enhancing mold durability and performance through advanced materials. Recent trends in the injection molding market highlight the importance of innovative materials and processes in achieving these enhancements. For instance, studies have shown that incorporating carbon fiber reinforced thermoplastics (CFRTs) can lead to significant improvements in the performance and longevity of molds, enabling manufacturers to meet stringent production demands while ensuring structural integrity. These high-performance materials not only contribute to lightweight designs but also ensure superior strength and durability under various manufacturing conditions.

Furthermore, advancements in mold design, such as the application of Bayesian optimization techniques, allow for a more precise parametrization of rib structures within components. This methodology enhances the structural stiffness of parts like tailgates while maintaining compliance with manufacturing constraints inherent in injection molding processes. By leveraging such innovative engineering strategies and materials, the automotive industry can achieve a remarkable balance between efficiency, performance, and sustainability in mold production, leading to a transformative impact on the overall manufacturing landscape.

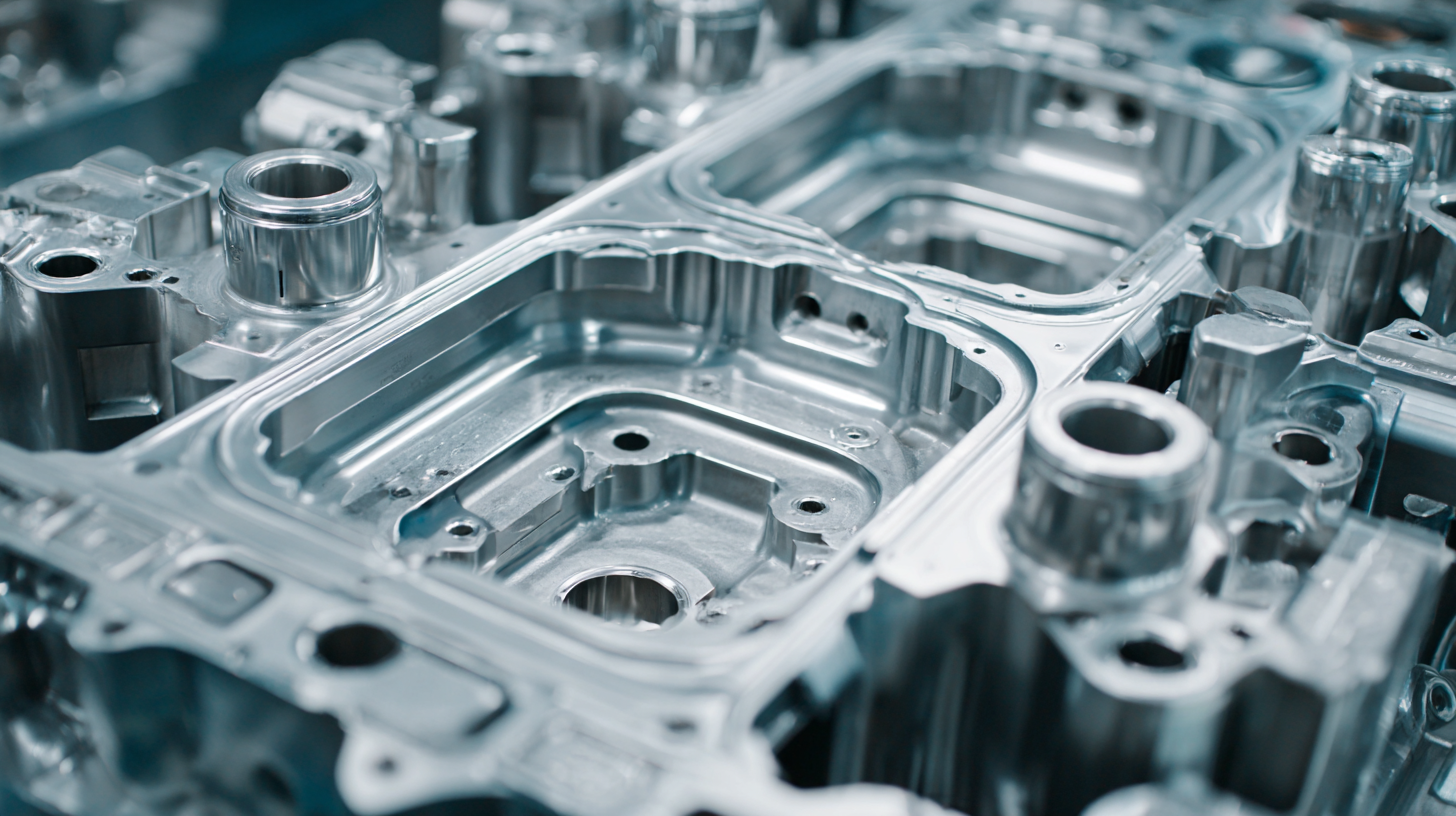

Implementing Lean Manufacturing Principles in mold production is crucial for optimizing automotive parts molds. Lean manufacturing focuses on eliminating waste and improving efficiency, which can significantly enhance the production process of molds. By analyzing every step of the mold production workflow, manufacturers can identify non-value-added activities and streamline operations. This includes reducing excessive inventory, minimizing wait times between processes, and enhancing communication among various teams involved in production.

One effective strategy is the adoption of value stream mapping, which helps in visualizing the flow of materials and information through various processes. This tool enables manufacturers to pinpoint bottlenecks and areas where delays occur, allowing for targeted improvements. Additionally, adopting just-in-time (JIT) inventory practices can dramatically cut down on storage costs and waste associated with overproduction. Empowering employees through training on lean principles fosters a culture of continuous improvement, ensuring that the team remains engaged and proactive in seeking efficiencies.

Data analytics is revolutionizing the automotive parts mold production industry, offering powerful insights that drive continuous improvement in efficiency. By leveraging data from production processes, manufacturers can identify bottlenecks, optimize workflows, and increase yield. According to a recent report by the Boston Consulting Group, companies utilizing advanced analytics in manufacturing can boost their production efficiency by up to 20%. This capability not only enhances operational performance but also significantly reduces costs associated with downtime and waste.

**Tips:** Regularly collect data on machine performance and production cycles to create benchmarks that can help identify areas for improvement. Additionally, employing predictive analytics can foresee potential failures, allowing for proactive maintenance that maximizes uptime.

Incorporating data analytics into the production strategy also facilitates improved decision-making. For instance, real-time analytics can help engineers evaluate mold performance and make necessary adjustments on the fly. A survey by Deloitte found that organizations that embraced data-driven decision-making were 5 times more likely to make faster decisions than their competitors. Utilizing these analytics fosters an environment of ongoing improvement, leading to sustainable efficiency gains and a competitive edge in the automotive sector.

**Tips:** Establish a cross-functional team to review analytics insights regularly. This collaborative approach not only enhances data interpretation but also encourages innovative ideas for process improvement.