In today's competitive manufacturing landscape, leveraging Advanced Mold Technology has become essential for companies aiming to enhance global sourcing efficiency. According to a recent report by MarketsandMarkets, the global mold market is projected to reach USD 10.5 billion by 2025, driven by rising demand for innovative production solutions. Studies indicate that employing advanced molding techniques can reduce production time by up to 30% while significantly lowering costs through optimized resource allocation. As industries increasingly demand precision and speed, implementing advanced technologies in mold design and production is no longer optional; it is a critical component for sustaining competitive advantage. This data-driven guide seeks to provide insights into effectively harnessing Advanced Mold Technology to streamline sourcing processes, ensuring that businesses not only stay relevant but also lead in an evolving marketplace.

Advanced mold technology is reshaping the landscape of global sourcing efficiency by providing innovative solutions that enhance production capabilities. By integrating lightweight materials, such as high-strength steels and advanced composites, manufacturers can significantly reduce the overall weight of products while improving structural integrity. This not only leads to decreased material costs but also promotes sustainability efforts as companies strive to meet eco-friendly standards. The use of advanced molds in conjunction with these materials allows for intricate designs and optimized production processes, helping businesses stay competitive in a rapidly evolving market.

The evolution of mold technology also impacts the production of high-tech applications, from automotive components to advanced semiconductors. Enhanced printing techniques and innovative manufacturing methodologies pave the way for complex designs that were previously challenging to achieve. As the plastic injection molding market expands, understanding the implications of these technological advancements is crucial for companies looking to maximize their sourcing efficiency. By leveraging these cutting-edge technologies, organizations can streamline operations and ultimately drive growth in a sustainability-conscious world, making informed decisions based on data-driven insights.

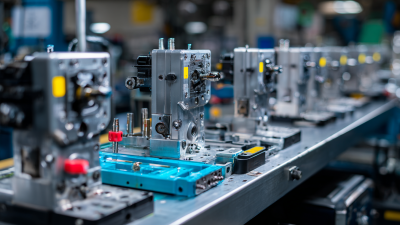

Advanced mold technology has revolutionized global supply chains, offering numerous benefits that enhance efficiency and productivity. One of the key advantages is the precision it brings to manufacturing processes. With advanced molds, companies can achieve higher tolerances and better surface finishes, reducing the need for post-processing and rework. This not only minimizes production time but also cuts costs, allowing organizations to allocate resources more effectively.

Additionally, the durability and longevity of advanced molds play a crucial role in supply chain optimization. By using advanced materials and engineering techniques, these molds can withstand a greater number of production cycles without the risk of failure. This reliability ensures consistent quality in product output, fostering stronger relationships with suppliers and customers alike. Ultimately, the integration of advanced mold technology into sourcing strategies enables companies to streamline operations and respond more agilely to market demands, solidifying their competitive edge in the global marketplace.

Advanced molding techniques play a crucial role in enhancing product quality and consistency in manufacturing. By utilizing cutting-edge technologies such as injection molding, 3D printing, and micro-molding, companies can produce components that meet stringent quality standards while significantly reducing defects. These methods allow for precise control over material properties and dimensions, enabling the production of intricate designs that were previously unattainable. As a result, manufacturers can offer products that not only fulfill customer expectations but also stand out in a competitive marketplace.

Moreover, the implementation of advanced mold technology fosters a more efficient sourcing process. By leveraging data analytics and design simulation, businesses can identify optimal material selections and production methods early in the design phase. This proactive approach minimizes rework and waste, ensuring a streamlined supply chain that enhances overall operational efficiency. As companies increasingly switch to these innovative techniques, the benefits extend beyond product quality—driving sustainability and cost savings that are vital in today’s global economy. Thus, adopting advanced molding techniques is not just an investment in technology; it is a strategic move towards achieving excellence in product delivery and market responsiveness.

In the realm of global sourcing, data-driven decision making stands as a cornerstone for optimizing operations. Mold technology analytics offers profound insights that can significantly enhance sourcing efficiency. By leveraging real-time data from mold processes, businesses can identify patterns, forecast demand, and streamline production cycles. This analytical approach not only reduces waste but also ensures that resources are allocated where they are most needed, driving cost-effectiveness in an increasingly competitive market.

Furthermore, harnessing advanced mold technologies allows organizations to monitor performance metrics closely. By analyzing data points such as cycle times, defect rates, and machine efficiency, companies can make informed decisions that lead to enhanced product quality and faster time-to-market. Such insights empower sourcing teams to negotiate better with suppliers and make strategic choices that align with long-term business objectives. The integration of analytics into mold technology thus transforms traditional sourcing strategies into a proactive, data-centric model that fosters continuous improvement and innovation.

In today's competitive global marketplace, companies are constantly seeking ways to reduce costs while maintaining product quality. One effective strategy is to leverage advanced mold technology in global sourcing efforts. By utilizing high-precision molds, businesses can optimize their manufacturing processes, leading to substantial savings in both time and resources. Advanced mold solutions allow for the creation of complex designs with minimal material waste, which directly contributes to cost efficiency.

Moreover, the integration of data-driven insights into the mold-making process enhances decision-making capabilities. By analyzing historical production data, companies can identify the most effective mold designs and materials tailored to their specific needs. This data-centric approach not only streamlines the sourcing process but also reduces the likelihood of costly errors and reworks. Additionally, by sourcing molds from regions known for advanced manufacturing capabilities, businesses can tap into lower production costs while ensuring high-quality outputs. Embracing these strategies can transform global sourcing into a more efficient and cost-effective aspect of operations.