The demand for advanced electronic devices has soared in recent years, leading to a corresponding need for sophisticated Electronic Mold design techniques. According to a report by MarketsandMarkets, the global mold market is projected to reach $16.4 billion by 2027, with an increasing focus on innovations in electronics and precision engineering. As industries pursue greater efficiency, accuracy, and reduced lead times, mastering Electronic Mold design techniques becomes essential. This guide explores the intricacies of creating high-quality electronic molds, integrating insights from industry experts and cutting-edge research. Whether you are a seasoned professional or a newcomer to the field, understanding the latest methodologies and tools in Electronic Mold design will empower you to enhance product performance and streamline manufacturing processes.

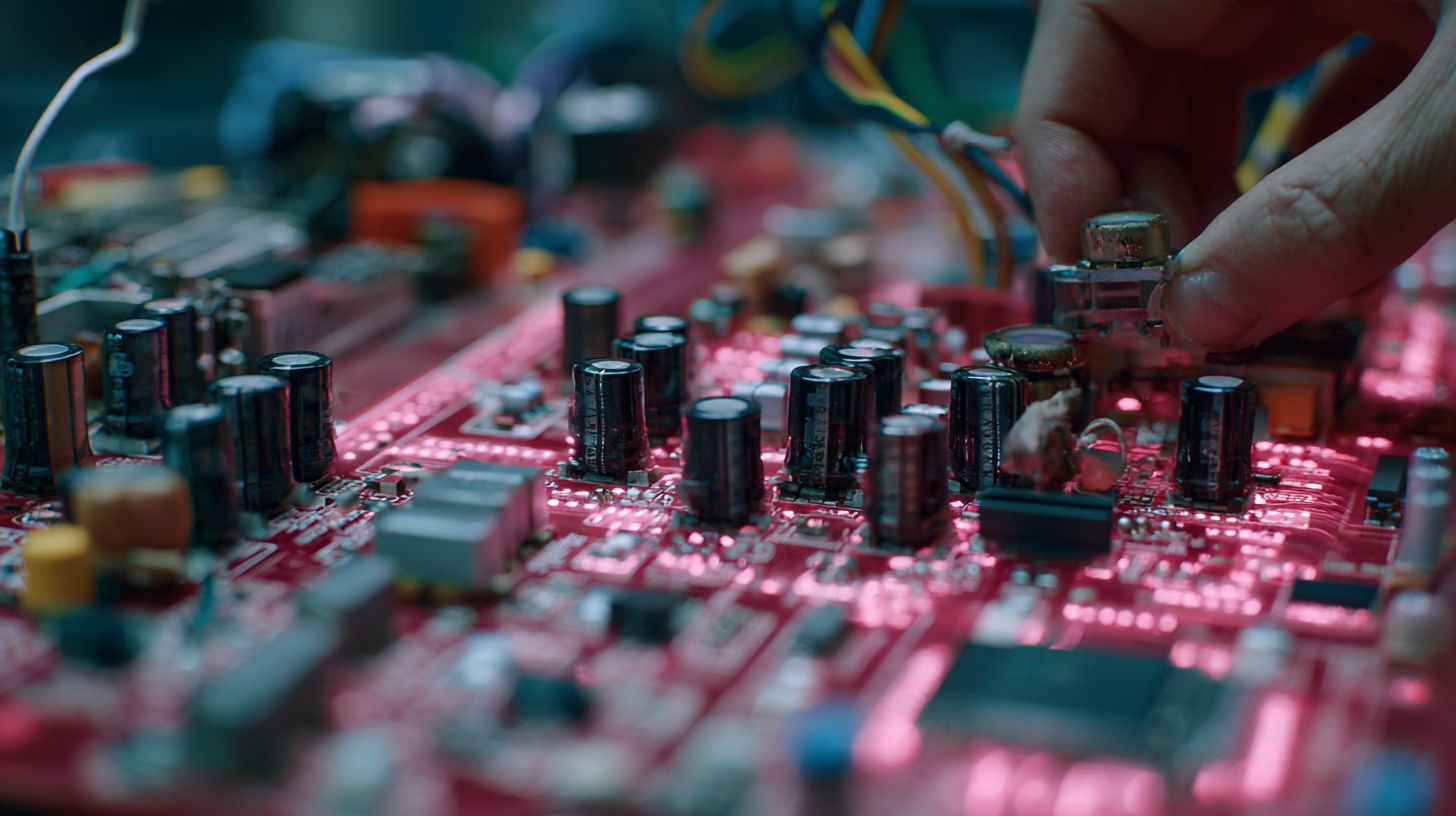

Understanding the fundamentals of electronic mold design is essential for creating effective and efficient products. At its core, electronic mold design involves the creation of specialized molds that are used to shape various electronic components. This process not only enhances the functionality of electronic devices but also improves their durability and aesthetics.

Tips: When beginning your journey in electronic mold design, focus on mastering the CAD software tools specific to mold design. Familiarize yourself with features such as parametric design, which can save time and resources during the prototyping phase. Additionally, ensure you understand the thermal dynamics involved in the molding process, as managing heat has a significant impact on material properties and the final quality of the molded parts.

Another critical aspect to consider is material selection. Different materials offer varying properties, affecting the performance of the electronic components. Tips: Conduct thorough research on the electrical and thermal conductivity of materials suitable for your project. Always choose materials that not only meet your design requirements but are also cost-effective and widely available. By understanding these basics, you will set a strong foundation for mastering the intricate techniques of electronic mold design.

This chart illustrates the key factors influencing the efficiency of electronic mold design techniques, highlighting the importance of each factor in the overall design process.

The realm of electronic mold design has evolved significantly, reinforced by advancements in tools and software that enhance productivity and precision. As highlighted in recent industry reports, the global market for mold design is projected to reach $10 billion by 2025, indicating a growing demand for effective and efficient design solutions. Key software like SolidWorks and Autodesk Moldflow are essential for virtual prototyping and simulation, enabling designers to anticipate issues and streamline production cycles.

The realm of electronic mold design has evolved significantly, reinforced by advancements in tools and software that enhance productivity and precision. As highlighted in recent industry reports, the global market for mold design is projected to reach $10 billion by 2025, indicating a growing demand for effective and efficient design solutions. Key software like SolidWorks and Autodesk Moldflow are essential for virtual prototyping and simulation, enabling designers to anticipate issues and streamline production cycles.

Tip: Familiarize yourself with the latest CAD software features, such as parametric modeling and simulation tools, which can drastically reduce turnaround times for mold designs.

Moreover, incorporating advanced tools such as 3D printing in prototyping allows for rapid iterations and testing of mold designs, aligning with the 50% reduction in lead times reported by many industry leaders. Integrated software platforms that combine design and manufacturing processes can lead to significant cost savings and improved accuracy.

Tip: Invest in cloud-based collaboration tools that facilitate real-time feedback and updates among team members, ensuring that everyone is aligned throughout the design process.

As you adopt these essential tools, you will not only enhance your workflow but also stay at the forefront of mold design technology, positioning yourself for success in this dynamic field.

Creating 3D models for electronic molds is a crucial step in the production process, enhancing accuracy and efficiency. The first step involves selecting the right software that aligns with your design requirements. Popular choices include SolidWorks, Rhino, and Autodesk Fusion 360. These platforms offer powerful tools for modeling intricate designs, allowing for precise adjustments as you develop your mold concept. Familiarizing yourself with the software's interface and capabilities can significantly enhance your productivity and effectiveness in mold design.

Once you've chosen your software, the next step is to sketch your initial ideas. Start by defining the mold’s geometry based on the product specifications. Utilize the sketching tools within your chosen software to create a basic outline. As you refine the design, incorporate features like draft angles and undercuts, which are essential for easy part removal. The ability to visualize and manipulate your design in 3D will allow for better decision-making and adjustments as needed, ensuring that the final product meets all functional requirements and quality standards.

Electronic mold design plays a pivotal role in the ever-evolving world of automotive electronics. As the integration of advanced technologies in vehicles accelerates, the challenges in mold design become more pronounced. A critical hurdle is ensuring the reliability of circuit boards, especially in vehicle systems where the demand for advanced driver assistance systems (ADAS) and autonomous driving technologies continues to rise. Industry reports indicate that the automotive electronics market is projected to reach over $400 billion by 2026, underlining the urgency to address these mold design challenges effectively.

One significant challenge is thermal management, which is exacerbated by the increased number of electronic components used in modern vehicles. For instance, the shift towards 48V systems has created new requirements for power management solutions, pushing the boundaries of design specifications. The efficient use of materials, such as SiC and GaN in power electronics, can mitigate these issues, improving performance and reliability. According to recent studies, advancements in these technologies can enhance efficiency by up to 30%, giving designers robust tools to overcome the thermal and reliability challenges inherent in electronic mold design.

When it comes to prototyping and testing mold designs, adhering to best practices is essential for ensuring quality and efficiency. According to a report by the American Society of Mechanical Engineers (ASME), about 25% of production costs can be attributed to mold design and manufacturing. Therefore, investing time in effective prototyping strategies not only enhances product quality but also significantly reduces costs associated with iterations and redesigns.

Utilizing advanced simulation tools can streamline the prototyping process. The Moldflow analysis software, for instance, allows designers to predict how molten plastic will flow within a mold cavity, helping to identify potential defects early on. This approach can decrease cycle time by up to 30%, making it a preferred choice in the industry. Additionally, real-world testing with prototypes is vital; a study from the Society of Plastics Engineers (SPE) indicates that prototypes that undergo rigorous testing outperform their less-examined counterparts by 40% in terms of durability and functionality. Leveraging these practices not only drives innovation but also ensures that mold designs meet market demands efficiently.

| Technique | Description | Best Practices | Testing Method |

|---|---|---|---|

| 3D CAD Modeling | Creating a detailed digital model of the mold. | Utilize parametric design for flexibility. | Simulation software to analyze stresses. |

| Rapid Prototyping | Quickly creating a model to visualize and test design. | Choose appropriate materials for accuracy. | Physical testing for fit and design validation. |

| Thermal Analysis | Evaluating the thermal properties of the mold. | Optimize cooling channels to improve cycle times. | Use thermal imaging to identify hotspots. |

| Finite Element Analysis (FEA) | Analyzing the physical behavior of the mold under stress. | Ensure mesh refinement for accuracy. | Compare simulation results to physical tests. |

| Material Selection | Choosing appropriate materials for mold durability and performance. | Consider thermal and mechanical properties. | Conduct material testing for compliance. |