The mold market is undergoing significant transformations, driven by advancements in technology, increasing consumer demands, and evolving regulatory landscapes. According to a recent report by Markets and Markets, the global mold market is expected to reach USD 16.76 billion by 2026, expanding at a CAGR of 5.3% from 2021. This growth presents both opportunities and challenges for businesses operating within the sector. To achieve sustainable business success, a thorough Analysis Of Mold Market Trends is essential for stakeholders, enabling them to make informed decisions and adapt to emerging patterns. Emphasizing innovation, sustainability, and quality will be crucial in leveraging the evolving trends in this dynamic market. By understanding the shifting landscape, businesses can better position themselves to capture market share and meet the demands of a diverse clientele.

The mold market is undergoing significant transformations, driven by advancements in technology, increasing consumer demands, and evolving regulatory landscapes. According to a recent report by Markets and Markets, the global mold market is expected to reach USD 16.76 billion by 2026, expanding at a CAGR of 5.3% from 2021. This growth presents both opportunities and challenges for businesses operating within the sector. To achieve sustainable business success, a thorough Analysis Of Mold Market Trends is essential for stakeholders, enabling them to make informed decisions and adapt to emerging patterns. Emphasizing innovation, sustainability, and quality will be crucial in leveraging the evolving trends in this dynamic market. By understanding the shifting landscape, businesses can better position themselves to capture market share and meet the demands of a diverse clientele.

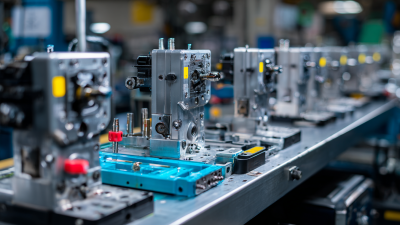

The current mold market is experiencing significant transformations influenced by various factors, including

technological advancements,

sustainability demands, and shifting consumer preferences. Businesses must closely monitor these trends to align

their strategies with market needs effectively. For instance, the rising emphasis on

eco-friendly materials

and manufacturing processes is reshaping product offerings. Companies that integrate sustainable practices not only

comply with regulations but also appeal to environmentally conscious consumers, enhancing their competitive

advantage.

Additionally, the growth of

automation and

smart manufacturing technologies is revolutionizing the production landscape.

Businesses that leverage these innovations can improve efficiency and reduce costs, allowing them to adapt swiftly

to changing market conditions. Emphasizing digital tools for design and production can lead to greater

customization options, meeting the unique demands of clients more effectively. As the mold market continues to

evolve, proactive engagement with these trends will be crucial for businesses aiming for

long-term success and relevance in a dynamic environment.

Additionally, the growth of

automation and

smart manufacturing technologies is revolutionizing the production landscape.

Businesses that leverage these innovations can improve efficiency and reduce costs, allowing them to adapt swiftly

to changing market conditions. Emphasizing digital tools for design and production can lead to greater

customization options, meeting the unique demands of clients more effectively. As the mold market continues to

evolve, proactive engagement with these trends will be crucial for businesses aiming for

long-term success and relevance in a dynamic environment.

The injection molding market is poised for significant growth, boasting a valuation of USD 365.22 billion in 2024, projected to reach USD 382.53 billion in 2025 and an impressive USD 580.44 billion by 2033, reflecting a compound annual growth rate (CAGR) of 4.74%. This upward trajectory highlights the increasing demand for molded components across various industries, including automotive, consumer goods, and electronics.

Key players in the mold industry must navigate this evolving landscape by conducting thorough competitor analyses. Factors such as pricing strategies, technological advancements, and sustainability initiatives will play crucial roles in determining market positions. As companies adapt to changing consumer preferences and regulatory requirements, understanding the competitive advantages of industry leaders becomes essential for business success. A detailed comparative analysis will not only illuminate the strengths and weaknesses of competitors but also offer insights into best practices and innovation opportunities in this dynamic market.

In the rapidly evolving mold market, leveraging new technologies in mold production can yield significant competitive advantages. Recent industry reports indicate that advanced production methods such as additive manufacturing and CNC machining have seen a 25% increase in usage over the last three years, proving to enhance precision and reduce lead times substantially. These technologies allow businesses to create complex mold designs that were previously unattainable, leading to improved product quality and customer satisfaction.

Tips: Consider investing in employee training for these new technologies. A skilled workforce can not only maximize the capabilities of advanced machinery but also foster innovation within your company. Moreover, exploring partnerships with tech firms specializing in mold production technologies might provide a unique advantage in accessing cutting-edge resources.

Additionally, the adoption of smart manufacturing techniques, like IoT-enabled machinery, is becoming increasingly prevalent. Current studies show that companies utilizing IoT in mold production are able to reduce production downtime by up to 30%. By implementing real-time monitoring and predictive maintenance, businesses can optimize their production processes and respond swiftly to market demands.

Tips: Regularly evaluate and adapt your technology strategy to stay ahead of competitors. Conduct thorough market research to identify which technologies align best with your business goals and customer needs. This proactive approach can position your company as a leader in the mold production industry.

In the mold industry, identifying your target audience is paramount to achieving business success. Market segmentation allows businesses to tailor their products and marketing strategies to meet the diverse needs of their customers. Understanding the demographics, behaviors, and preferences of specific groups will enhance outreach and strengthen brand loyalty.

**Tips for Effective Market Segmentation:**

1. **Conduct Thorough Market Research:** Utilize surveys and industry reports to gather data on potential customers. Analyze trends, preferences, and spending behaviors to gain insights into different segments.

2. **Define Your Segments Clearly:** Break your audience down into distinct groups based on attributes such as industry type, company size, and geographic location. This clarity will enable focused marketing efforts.

3. **Engage with Your Target Audience:** Develop relationships through personalized communication and feedback. Use social media and industry events to better understand their needs and build trust.

By implementing these strategies, businesses in the mold market can effectively identify and connect with their target audience, paving the way for sustainable growth and competitive advantage.

| Segment | Description | Market Share (%) | Growth Rate (CAGR %) | Key Applications |

|---|---|---|---|---|

| Automotive | Molds used in the production of automotive components. | 35% | 5% | Interior Parts, Engine Components |

| Consumer Goods | Molds utilized for household items and appliances. | 30% | 4% | Containers, Kitchenware |

| Industrial | Molds for industrial machinery and equipment. | 20% | 6% | Machinery Parts, Tooling |

| Medical | Molds for manufacturing medical devices and components. | 10% | 7% | Surgical Tools, Packaging |

| Electronics | Molds for electronic housings and components. | 5% | 3% | Casings, Connectors |

Sustainability has become a critical focus in mold manufacturing, as companies increasingly recognize the environmental implications of their production processes. Top firms in the industry are implementing eco-friendly practices to reduce waste and minimize their carbon footprint. For instance, many manufacturers are investing in renewable energy sources, such as solar and wind power, to run their production facilities. This shift not only lowers greenhouse gas emissions but can also result in cost savings over time. Furthermore, companies are optimizing their supply chains to source materials that are recyclable or derived from sustainable sources, ensuring that every step of the manufacturing process aligns with eco-conscious principles.

Additionally, leading firms are adopting advanced technologies to enhance sustainability. Utilization of 3D printing, for example, allows for precise mold creation while minimizing material waste. This method also facilitates rapid prototyping, enabling quicker design iterations without the ecological costs of traditional production techniques. Furthermore, many mold manufacturers are focusing on designing products that are easier to recycle or refurbish, extending their lifecycle and reducing landfill contributions. By committing to these sustainable practices, companies not only meet growing consumer demands for eco-friendly products but also position themselves advantageously in a competitive market that increasingly values environmental responsibility.