In 2023, the manufacturing landscape is witnessing a profound transformation driven by advancements in Automation Equipment Molds, which are becoming essential in the pursuit of enhanced efficiency and productivity. According to a report by McKinsey, automation could potentially increase global productivity by up to 1.4% annually, significantly impacting various sectors, including automotive, electronics, and consumer goods.

As companies increasingly adopt automated solutions, the demand for innovative molds designed to optimize production processes is rising sharply. These molds not only improve precision and reduce waste, but also enable manufacturers to accelerate their time-to-market. With Gartner predicting that 70% of organizations will have adopted some form of automation by 2025, understanding the revolutionary equipment molds available today is crucial for businesses aiming to stay competitive and leverage the full benefits of automation technology.

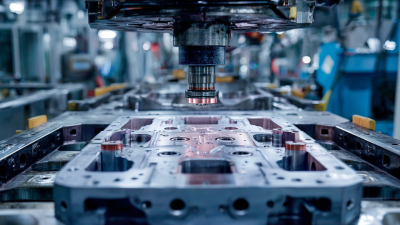

The rise of automation equipment molds is reshaping the manufacturing landscape in 2023. As per a report by McKinsey, companies that integrate advanced automation technologies into their operations could see productivity gains of up to 20-30%. This shift not only accelerates production rates but also reduces the chances of human error, which can be as high as 80% in manual processes. The adoption of these innovative molds allows manufacturers to streamline workflows, optimize material usage, and significantly reduce lead times, fostering a more agile production environment.

Moreover, a recent study by the International Federation of Robotics highlighted that the global market for industrial robots is projected to reach $75 billion by 2028, growing at a CAGR of 26%, with automation equipment molds being a key driver. These molds not only facilitate complex designs and high precision but also support the production of customizable products that meet the evolving demands of consumers today. As automation continues to integrate into manufacturing processes, companies leveraging these technologies will not only enhance their competitive edge but also drive the industry towards greater sustainability and efficiency.

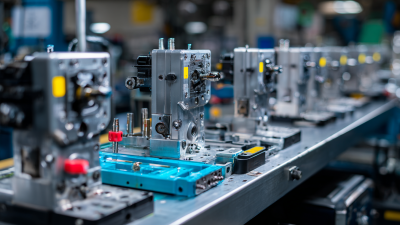

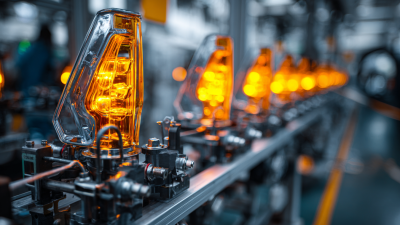

In 2023, the manufacturing landscape is undergoing a transformative shift with the advent of smart molds that enhance precision and redefine product quality standards. These advanced molds utilize integrated sensors and sophisticated software to monitor and adjust production processes in real-time. This level of automation allows for minimal human intervention while ensuring that each component meets stringent quality requirements. As a result, defects are significantly reduced, leading to higher customer satisfaction and lower rework costs.

Moreover, smart molds enable manufacturers to maintain consistency across their product lines. By leveraging data analytics, companies can fine-tune their production parameters and identify potential issues before they escalate. This predictive capability not only streamlines operations but also fosters an environment of continuous improvement. As industries embrace these revolutionary technologies, the focus on enhanced precision and quality will undoubtedly set new benchmarks for excellence in manufacturing, ultimately driving growth and competitiveness in the market.

In 2023, the manufacturing landscape is undergoing a significant transformation with the introduction of revolutionary automation equipment molds, aimed at enhancing operational efficiency. As industries strive for cost efficiency, the analysis of return on investment (ROI) from automation has gained paramount importance. A recent report indicates that the global robotic process automation market is projected to grow from $22.58 billion in 2025 to $72.64 billion by 2032, boasting a remarkable compound annual growth rate (CAGR) of 18.2%. This growth reflects the increasing reliance on automation to streamline processes, reduce manual errors, and ultimately cut costs.

Moreover, the packaging automation sector is also witnessing robust expansion, with market projections suggesting an increase from $78.27 billion in 2025 to $134.65 billion by 2032, translating to an annual growth rate of 8.06%. As manufacturers increasingly adopt automation technologies, the trend indicates not just enhancement in efficiency but also a significant boost in productivity and profitability. Businesses that strategically invest in automation solutions are likely to see substantial ROI, underscoring the critical role of innovation in modern manufacturing processes.

Real-time monitoring has become a cornerstone in enhancing manufacturing efficiency, especially with the integration of Internet of Things (IoT) technology. According to a report by McKinsey, manufacturers that leverage IoT capabilities can expect to see efficiency improvements of up to 30%. This dramatic increase is driven by IoT devices that provide real-time data on machinery performance, enabling companies to identify bottlenecks and optimize workflows swiftly. By connecting machinery and equipment to the cloud, manufacturers can gain insights into operational health, predict failures before they occur, and reduce downtime significantly.

Furthermore, research from Deloitte indicates that IoT-driven automation can lead to cost reductions of around 20% in overall manufacturing operations. These savings arise not only from improved productivity but also from enhanced resource allocation. For instance, manufacturers can better manage their supply chains as IoT sensors monitor inventory levels in real time, ensuring that resources are used efficiently and waste is minimized. As the industry continues to embrace these technologies, the role of real-time monitoring will undoubtedly evolve, leading to even smarter and more adaptable manufacturing ecosystems.

In recent years, the push towards sustainability in manufacturing has accelerated, driven by automation innovations that not only enhance efficiency but also reduce environmental impact. The integration of advanced technologies is enabling manufacturers to adopt eco-friendly practices that align with global sustainability goals. For instance, the application of digital twins in food and beverage production is revolutionizing how ingredients are processed, fostering a more sustainable approach to resource management.

**Tip:** To optimize sustainable practices, consider investing in automation technologies that offer transparency in resource usage and waste management. This can significantly reduce the carbon footprint while improving operational efficiency.

Furthermore, industries ranging from fashion to textiles are embracing sustainable practices by incorporating innovative technologies in their production processes. The advancements in knitting technology have not only increased production efficiency but also minimized material waste. As the demand for eco-friendly products rises, manufacturers must adapt by leveraging such technologies and forming strategic partnerships that prioritize sustainability.

**Tip:** Collaborate with technology providers focused on sustainable innovations to enhance your production processes. Shared expertise can lead to more sustainable outcomes and foster a responsible manufacturing environment.