The automotive industry is undergoing a significant transformation driven by advancements in connectivity and the increasing complexity of vehicle electronics. As vehicles become more integrated with sophisticated technologies such as autonomous driving systems, electric powertrains, and infotainment platforms, the demand for reliable and efficient connections between various electronic components is paramount. According to a recent report by MarketsandMarkets, the global automotive connectors market is projected to grow from $23.6 billion in 2022 to $37.9 billion by 2027, highlighting the critical role of automotive connector mold innovations in meeting this escalating requirement.

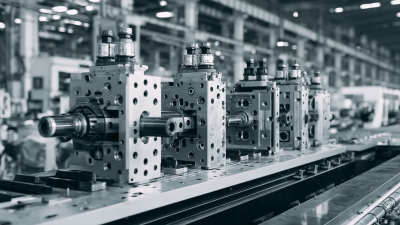

At the heart of these developments is the automotive connector mold, which serves as a vital component in ensuring optimal performance and durability in automotive applications. The evolution of connector molding technology is not only enhancing the reliability of automotive connectors but also enabling manufacturers to respond to the growing need for miniaturization and lightweight materials. Expectations for faster data transmission speeds, coupled with the increasing integration of smart technologies within vehicles, necessitate advanced molding techniques that can accommodate higher performance standards. Thus, the future of automotive connectivity significantly hinges on revolutionary advancements in connector molding technology, promising a new era of enhanced functionality and reliability in the automotive sector.

Connector molding technology has emerged as a pivotal advancement in the automotive industry, particularly with the rise of electric vehicles (EVs) and automated driving systems. According to a recent report by MarketsandMarkets, the automotive connector market is projected to reach $22.75 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This surge is largely driven by the increasing complexity of vehicle electronic systems and the demand for reliable, lightweight, and cost-effective connectivity solutions.

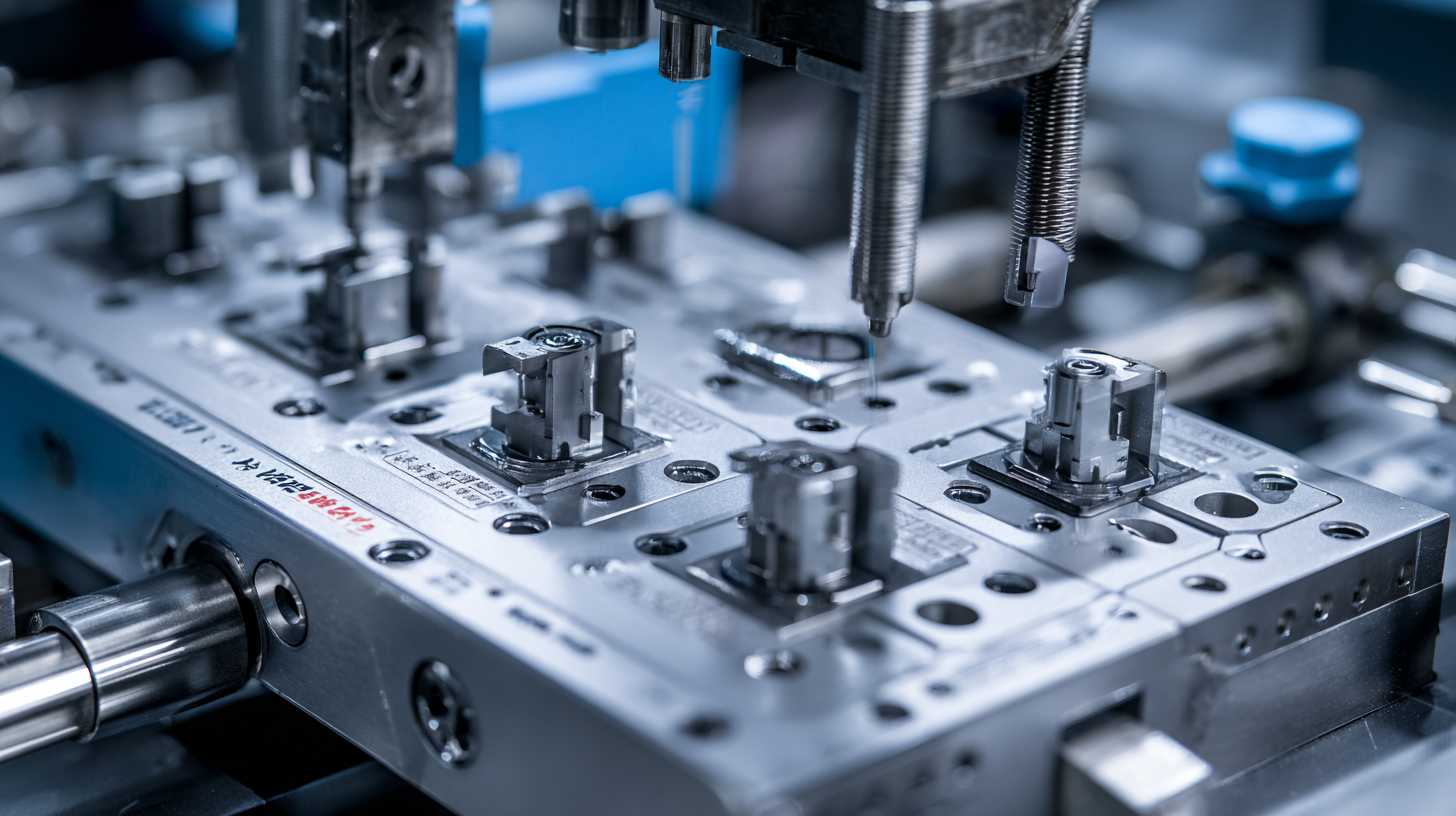

One significant advancement in connector molding technology is the development of over-molding techniques, which enhance the durability and performance of connectors in extreme automotive environments. These innovations not only improve resistance to moisture, heat, and vibration but also allow for more compact designs, which is crucial in the tight spaces of modern vehicle architectures. The integration of smart technology within connectors is also gaining traction, enabling real-time data transmission and diagnostics, which can further enhance vehicle safety and performance metrics.

**Tip:** When considering connector options for automotive applications, prioritize those that offer high-temperature resistance and enhanced environmental sealing to ensure maximum reliability. Additionally, opt for connectors that facilitate modular designs, allowing for easier upgrades and replacements as technology evolves in the automotive sector.

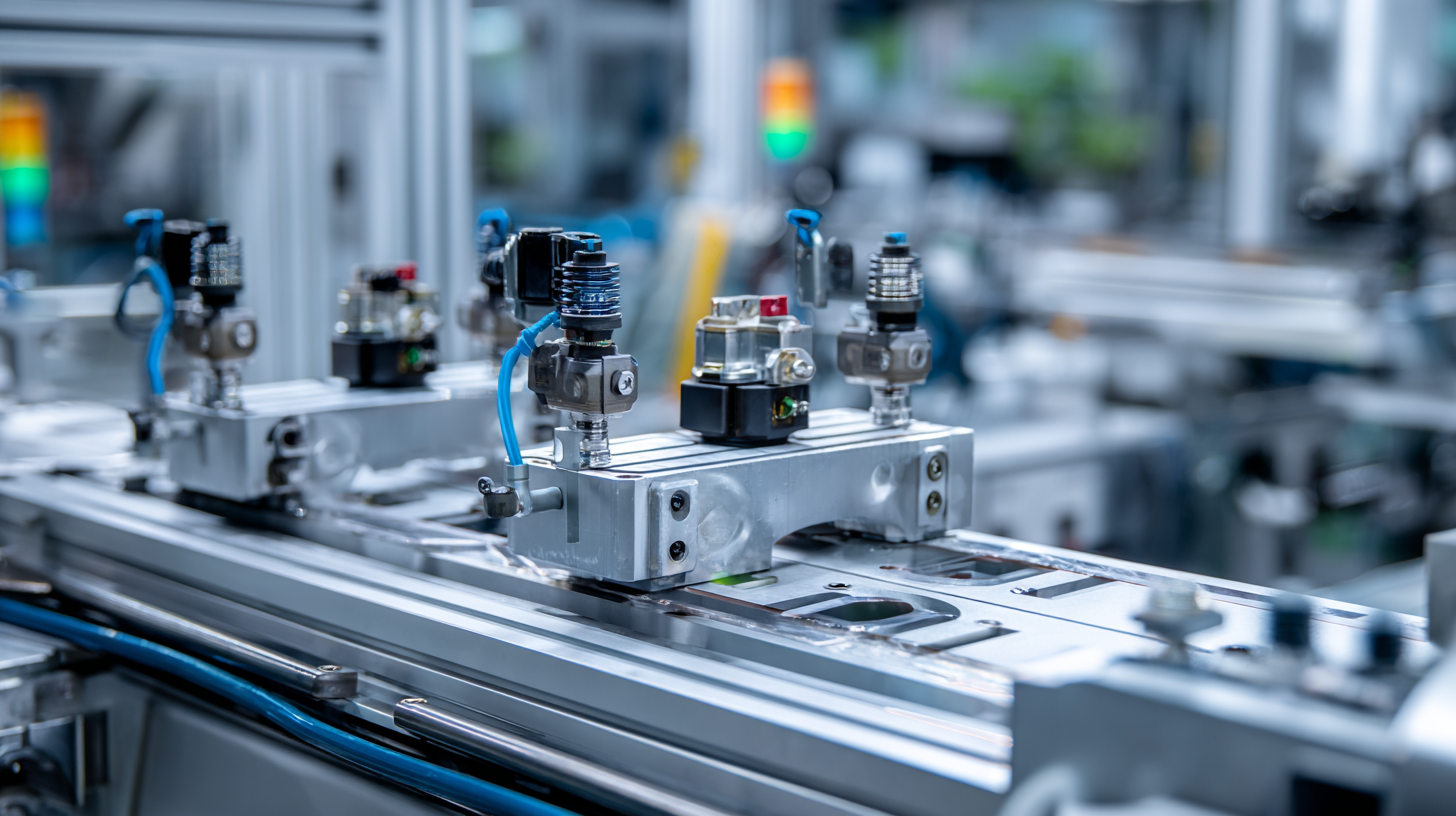

The automotive industry is experiencing a transformative shift driven by advancements in connector molding technology. One of the primary key drivers of change is the increasing demand for enhanced vehicle connectivity. As the integration of smart devices and Internet of Things (IoT) capabilities in vehicles accelerates, manufacturers are compelled to develop connectors that can support higher data rates and greater reliability. This surge in connectivity not only improves driver convenience and safety but also facilitates vehicle-to-everything (V2X) communication, paving the way for more intelligent transportation systems.

Another significant driver is the growing emphasis on lightweight materials to optimize vehicle performance and fuel efficiency. Connector molding technology is evolving to incorporate advanced polymers and composites that reduce weight while maintaining strength and durability. This shift aligns with the automotive industry’s sustainability goals and the push towards electric and hybrid vehicles, which require efficient energy management systems. As the future of automotive connectivity unfolds, these technological advancements will play a crucial role in shaping smarter, more efficient, and sustainable vehicles.

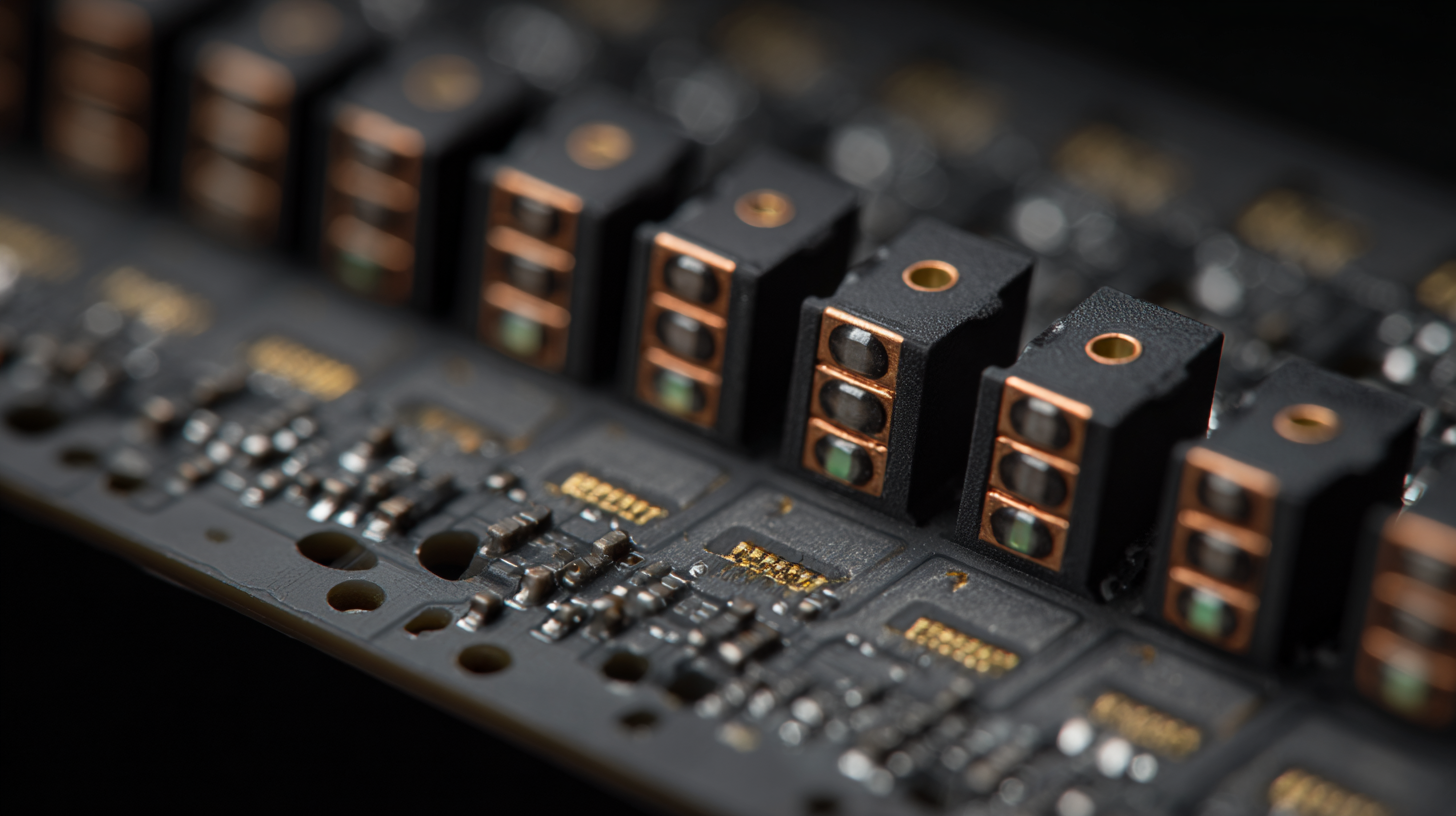

The advancement of connector molding technology plays a pivotal role in the automotive industry's shift towards enhanced connectivity. As vehicles increasingly rely on sophisticated electronic systems for communication, entertainment, and safety, the demand for durable and high-performance connectors becomes paramount. Innovative materials are at the forefront of this transformation, offering improved resistance to environmental factors such as temperature fluctuations, moisture, and vibration, which are critical for maintaining the integrity of automotive connections.

One of the key innovations in connector materials is the use of advanced thermoplastics and composite materials. These materials not only provide exceptional durability but also reduce weight, contributing to overall vehicle efficiency. Additionally, the incorporation of nanotechnology in the molding process enhances the electrical conductivity of connectors while maintaining their mechanical strength. This synergy of innovative materials and engineering techniques is essential for producing connectors that can withstand the rigors of modern automotive applications, ensuring reliable performance and longevity. As automotive connectivity continues to evolve, the emphasis on material innovation will significantly shape the future of connector technology.

| Material Type | Durability Rating | Temperature Resistance (°C) | Electrical Conductivity (S/m) | Weight (g/m) |

|---|---|---|---|---|

| Polyphenylene Sulfide (PPS) | High | 200 | 0.06 | 1.20 |

| Liquid Crystal Polymer (LCP) | Very High | 260 | 0.2 | 0.90 |

| Silicone Rubber | Medium | 180 | 1.0 | 2.50 |

| Thermoplastic Elastomer (TPE) | Medium | 150 | 0.1 | 1.50 |

| Polyamide (PA) | High | 230 | 0.5 | 1.80 |

The automotive industry is witnessing a significant transformation in connector design and manufacturing, driven by emerging technologies and the growing demand for electric vehicles (EVs). As vehicles become more connected and automated, the need for advanced connector molding technology has never been greater. According to a recent industry report, the global automotive connector market is projected to reach $30 billion by 2025, with a CAGR of approximately 10% from 2020. This growth is largely fueled by the increasing complexity of electrical systems in modern vehicles, emphasizing the necessity for innovative connector solutions that ensure reliability and performance.

As announced at the recent automotive exhibition in Shanghai, various manufacturers, including leaders in automotive technology, are prioritizing localization strategies to better serve regional markets. These strategies include investing in local manufacturing facilities, such as advanced production plants for new energy vehicles. With the automotive sector moving towards higher electrification and connectivity, meticulous attention to connector design, such as the integration of smart features and optimized molding techniques, is pivotal for enhancing vehicle functionality and safety. Reports indicate that the shift towards smart factories and the adoption of Industry 4.0 principles will further streamline connector manufacturing processes, thereby improving time-to-market for new automotive innovations.

The advent of smart technology is propelling the automotive industry into a new era of connectivity, fundamentally changing the design and function of connector systems. Unlike traditional connectors, smart connectors are embedded with advanced sensors and electronics that not only facilitate data transmission but also enhance vehicle diagnostics and maintenance. This integration allows for real-time monitoring of vehicle performance, ensuring that systems operate efficiently and proactively alerting drivers to potential issues before they become critical.

Moreover, the evolution of connector molding technology is crucial in accommodating these innovative smart systems. Manufacturers are now focusing on producing connectors that are not only reliable and durable but also capable of supporting high-speed data transfer and sophisticated communication protocols. This shift is essential for the development of interconnected automotive environments, such as vehicle-to-everything (V2X) communication, where vehicles exchange information with each other and infrastructure. As the industry moves toward more automated and connected vehicles, the role of smart technology in optimizing connector systems will be pivotal in shaping the future of automotive connectivity.