The rapid evolution of technology continues to transform various sectors, and the role of Electronic Hardware Molds has become increasingly pivotal in enhancing manufacturing efficiency and product quality. According to a recent report by MarketsandMarkets, the global market for electronic molding is projected to reach $12.4 billion by 2026, growing at a CAGR of 7.2%. This growth is driven by the rising demand for advanced electronic devices and the need for high precision in hardware components. As industries strive for innovation, the integration of cutting-edge materials and automation technologies in the production of Electronic Hardware Molds is set to revolutionize the landscape. With burgeoning applications across consumer electronics, automotive, and aerospace sectors, the future of Electronic Hardware Molds promises not only to enhance productivity but also to enable the design of more complex and multifunctional electronic components, ultimately reshaping the foundations of modern technology.

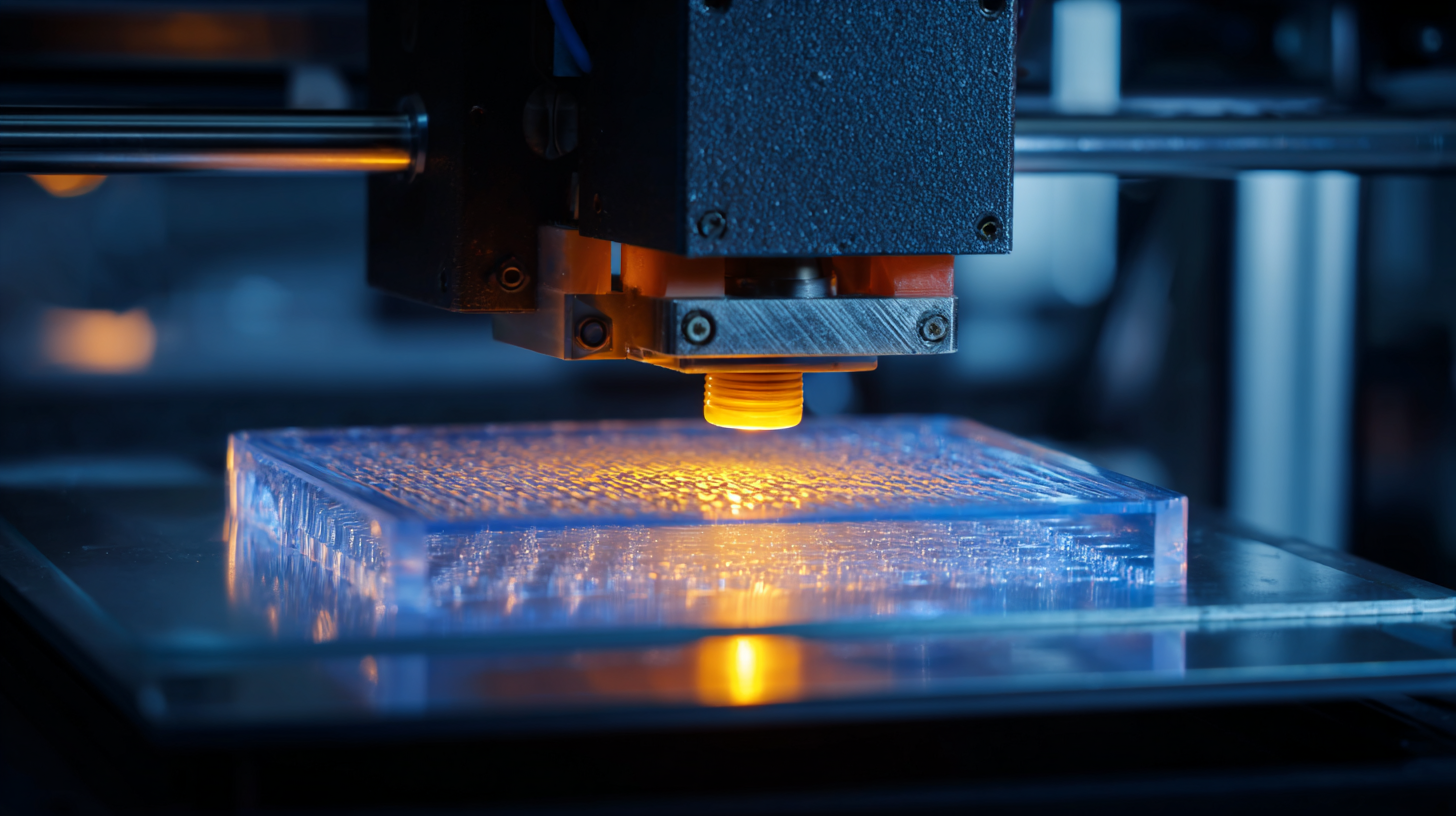

The landscape of electronic hardware mold design and production is set to undergo significant transformation driven by technological advancements and evolving market needs. One of the most notable trends is the increasing use of 3D printing technologies, which allows for rapid prototyping and customization of molds. This shift not only reduces lead times but also enables manufacturers to design complex geometries that were previously unattainable through traditional molding methods. As a result, companies can swiftly adapt to changing consumer demands, providing tailored solutions that enhance product performance and reduce waste.

Moreover, the integration of smart manufacturing practices is revolutionizing the production process. By incorporating IoT (Internet of Things) devices into the molding equipment, manufacturers can monitor production metrics in real time, leading to improved efficiency and quality control. Predictive maintenance driven by data analytics can minimize downtime, while AI-driven design tools can suggest optimal mold designs based on specific performance criteria. These innovations promise to streamline the entire production workflow and foster a more agile approach to electronic hardware manufacturing, ensuring that companies remain competitive in a rapidly evolving technological landscape.

This chart illustrates the projected growth in the adoption of advanced materials, automation, and sustainability practices in electronic hardware mold production over the next five years. The data reflects a significant trend toward modernizing mold design to meet the demands of innovation in technology.

Innovative materials are at the forefront of transforming electronic hardware molds, shaping the future of tech innovations. Recent developments highlight the significance of materials that enhance functionality and performance. For instance, the introduction of photocured transparent films utilizing graphene showcases the potential for next-generation optical materials. By leveraging graphene's stable dispersion and optical nonlinearity, these advancements promise to redefine the capabilities of electronic components, pushing the boundaries of what molds can achieve in various applications.

Additionally, the use of specialized compounds, such as High-K Epoxy Molding, marks a pivotal step in mobile DRAM production. These innovative materials not only improve thermal performance but also redefine manufacturing processes, enabling more compact and efficient designs. As industries explore advanced metals and sustainable options like circular carbon fibers, the evolution of mold technology is clearly driven by the continuous quest for materials that offer superior performance while addressing environmental concerns. The interplay of these innovations is set to revolutionize production in the tech sector, allowing for creative solutions that meet the demands of the future.

| Material Type | Properties | Applications | Benefits |

|---|---|---|---|

| Thermoplastics | Lightweight, Durable, Recyclable | Consumer Electronics, Automotive | Cost-effective, Eco-friendly |

| Silicone | High flexibility, Heat resistant | Medical Devices, Household Products | Long lifespan, Safe for various environments |

| Metals (Aluminum, Steel) | Strong, Conductive, Heat resistant | Heavy Machinery, Aerospace | High strength, Excellent durability |

| Composite Materials | Stiff, Lightweight, Corrosion resistant | Aerospace, Sporting Goods | Enhanced performance, Weight reduction |

| 3D Printed Materials | Customizable, Complex geometries | Prototypes, Custom Parts | Rapid production, Design flexibility |

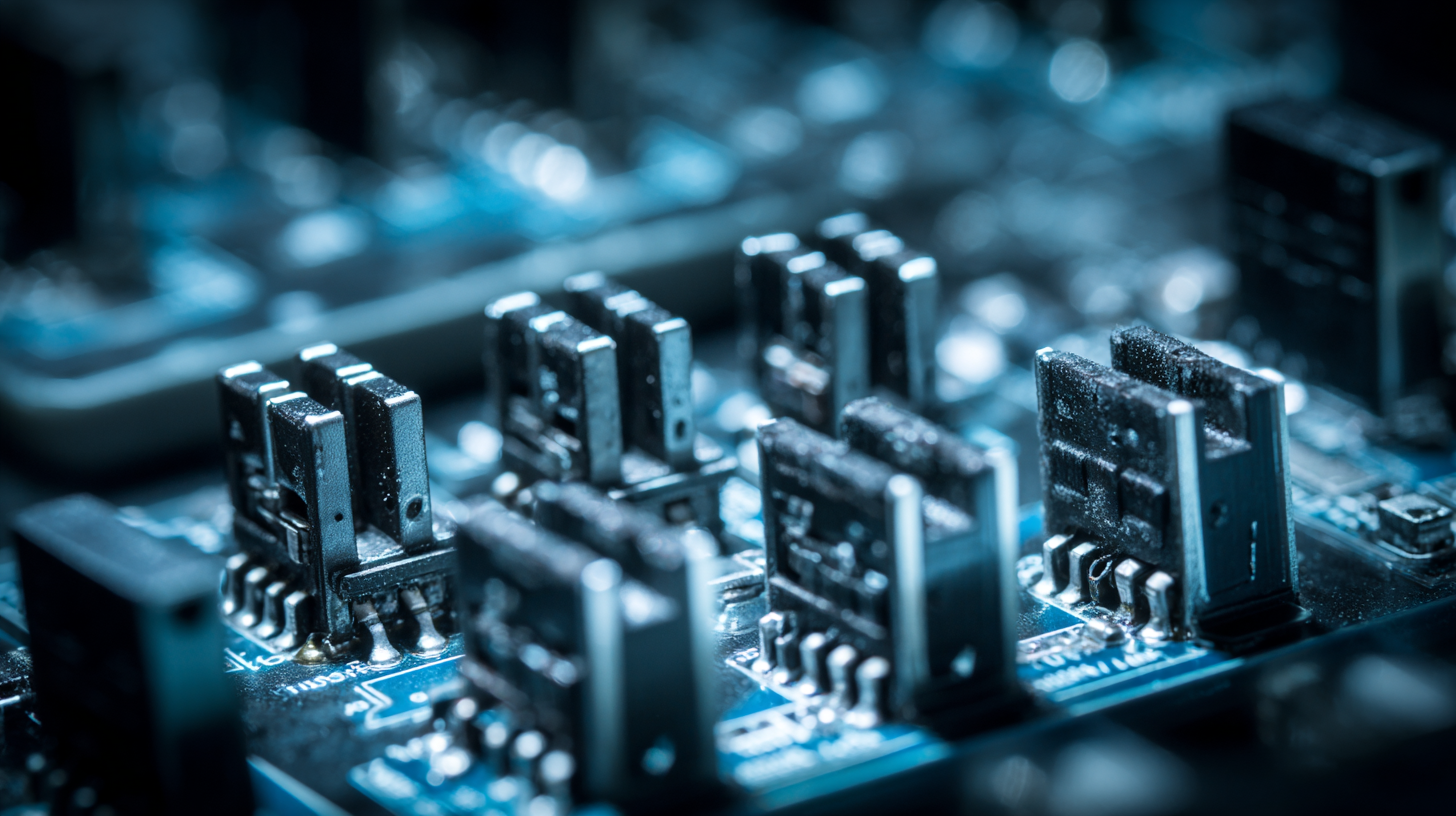

The integration of smart technology into hardware mold manufacturing is transforming the landscape of electronic hardware production. According to a report by Smithers Pira, the global market for smart manufacturing technologies is expected to reach $550 billion by 2025, indicating a significant shift towards automation and efficiency in production processes. This evolution allows manufacturers to leverage IoT and AI to enhance precision in mold design and production, ultimately reducing time-to-market and lowering costs.

Utilizing smart technologies not only streamlines production but also improves quality control. For instance, advanced sensors can monitor mold performance in real-time, detecting fluctuations that may indicate potential failures. A report from IDTechEx suggests that implementing smart sensors can decrease defect rates by up to 30%, thereby improving overall product quality and customer satisfaction. As electronics become increasingly complex, investing in smart mold manufacturing becomes essential, positioning companies to remain competitive in a rapidly changing market.

The electronic hardware industry is witnessing a significant shift towards sustainable practices, especially in the realm of mold production. Eco-friendly electronic molds are not just a trend; they represent the next wave of innovation that aligns with global sustainability goals. By utilizing biodegradable materials and adopting energy-efficient manufacturing processes, companies are reducing their carbon footprints and minimizing waste. This transformation not only benefits the environment but also enhances the marketability of products, as consumers increasingly favor brands that prioritize ecological responsibility.

Moreover, integrating sustainable practices in the production of electronic molds opens new avenues for technological advancements. Innovations such as 3D printing and modular design enable manufacturers to create complex shapes while using fewer resources. These methods also facilitate easier recycling and repurposing of molds, further contributing to a circular economy. As companies invest in research and development to enhance the sustainability of electronic hardware molds, they position themselves as leaders in the industry, paving the way for a more responsible and greener future in technology.

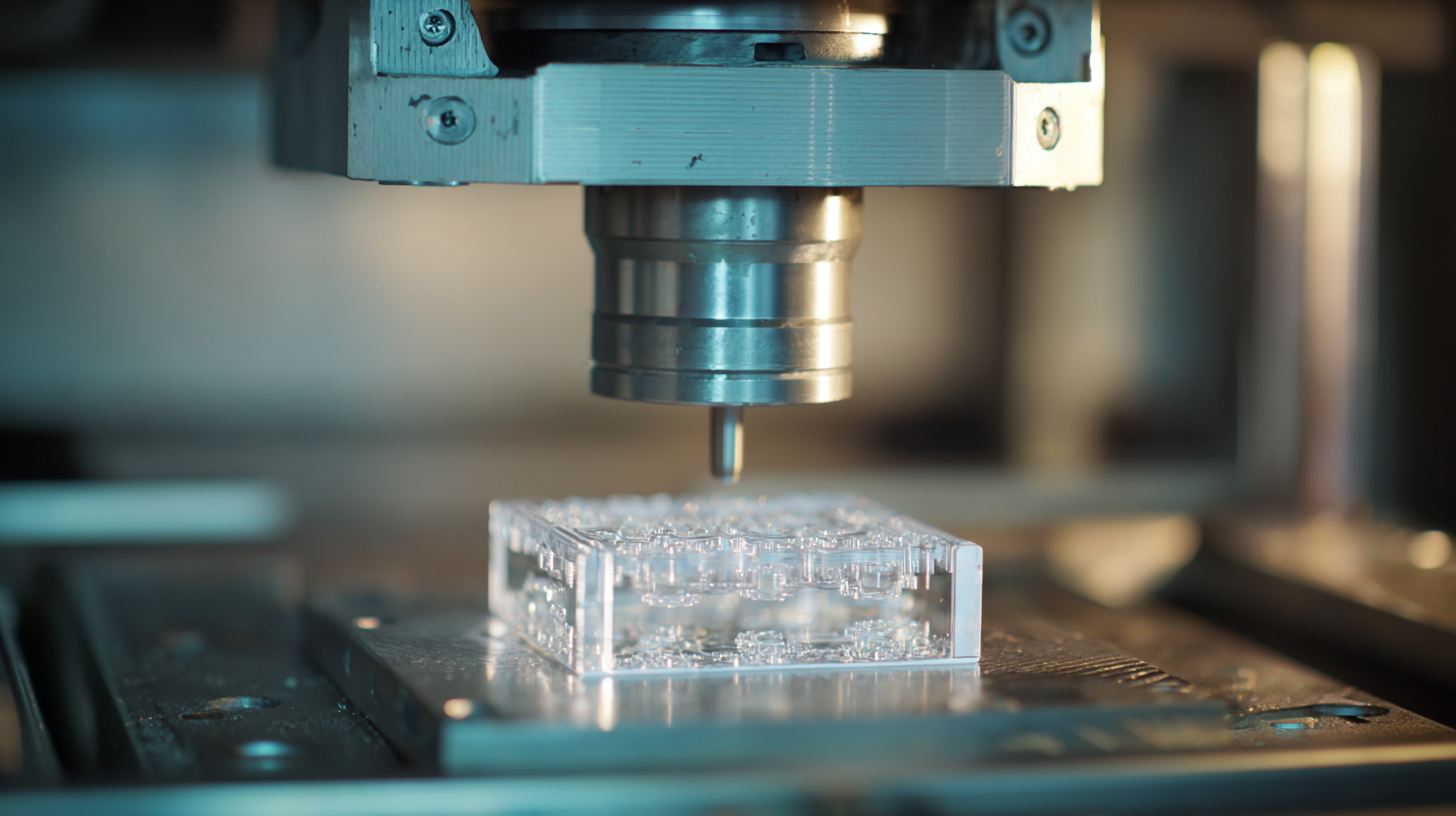

The future of electronic hardware molds is increasingly defined by customization and flexibility, key elements that address the evolving demands of the tech industry. According to a recent report by MarketsandMarkets, the global injection molding market is expected to grow from $232.8 billion in 2020 to $399.3 billion by 2026, reflecting an annual growth rate of 9.2%. This growth is largely attributed to the rising need for tailored solutions that meet specific product requirements across various tech sectors. Advanced mold production techniques, such as multi-material molding and rapid prototyping, have emerged as game-changers, enabling manufacturers to create more intricate and personalized designs.

The incorporation of Industry 4.0 principles into mold production processes further enhances customization and flexibility. By utilizing data analytics, machine learning, and IoT, companies can streamline production workflows and quickly adapt to changing market conditions. A study by the International Data Corporation (IDC) predicts that by 2025, over 50% of manufacturers will have implemented intelligent automation technologies, significantly improving their ability to deliver customized molds with shorter lead times. As a result, manufacturers not only enhance their competitiveness but also improve client satisfaction through bespoke solutions, ushering in a new era of innovation in electronic hardware design.