The transportation industry is undergoing a significant transformation driven by the rapid adoption of electric vehicles (EVs), which is projected to dominate the market in the coming decades. According to a recent report by the International Energy Agency, the global electric vehicle stock reached over 10 million units in 2020, with expectations to surpass 145 million by 2030. This remarkable growth has led manufacturers to innovate and enhance their production methods, notably through the development of specialized components such as the Electric Vehicle Mold. These advanced molds not only cater to the unique requirements of electric mobility but also optimize manufacturing efficiency and reduce costs. As EVs gain traction, the role of high-quality molds is becoming increasingly critical in ensuring that automotive manufacturers meet the demand for these cutting-edge vehicles while adhering to stringent environmental standards.

The innovations in electric vehicle mold technologies are significantly enhancing manufacturing efficiency across the automotive sector. As the electric vehicle battery box market is projected to grow from $253 million in 2024 to approximately $1.88 billion by 2032, representing a substantial annual growth rate of 29.7%, it's clear that advancements in mold design play a pivotal role in this expansion. Companies are increasingly investing in high-tech automated stamping tools, which streamline production processes and improve product quality, ensuring competitiveness in a rapidly evolving marketplace.

Moreover, the successful patent applications for new lightweight chassis technologies signal a shift towards automated and precise manufacturing methods. These innovations are not just about reducing costs; they enable manufacturers to respond proactively to the growing demand for high-precision automotive components. By integrating advanced mold technologies, the automotive industry can achieve unprecedented levels of production efficiency, ultimately benefiting the entire supply chain in the electric mobility landscape. Such developments underline the strategic importance of innovation in molds as manufacturers pivot towards an era characterized by smart and automated automotive solutions.

| Category | Application | Impact on Efficiency (%) | Sustainability Benefits | Material Innovations |

|---|---|---|---|---|

| Battery Enclosures | Advanced thermal management | 20% | Reduced energy consumption | Lightweight composites |

| Exterior Panels | Aerodynamic efficiency | 15% | Increased recyclability | High-strength polymers |

| Chassis Components | Structural integrity | 30% | Lower carbon footprint | Aluminum alloys |

| Interior Moldings | Enhanced user experience | 10% | Sustainable materials | Biodegradable plastics |

| Charging Connectors | Faster charging capabilities | 25% | Better energy efficiency | Copper alloys |

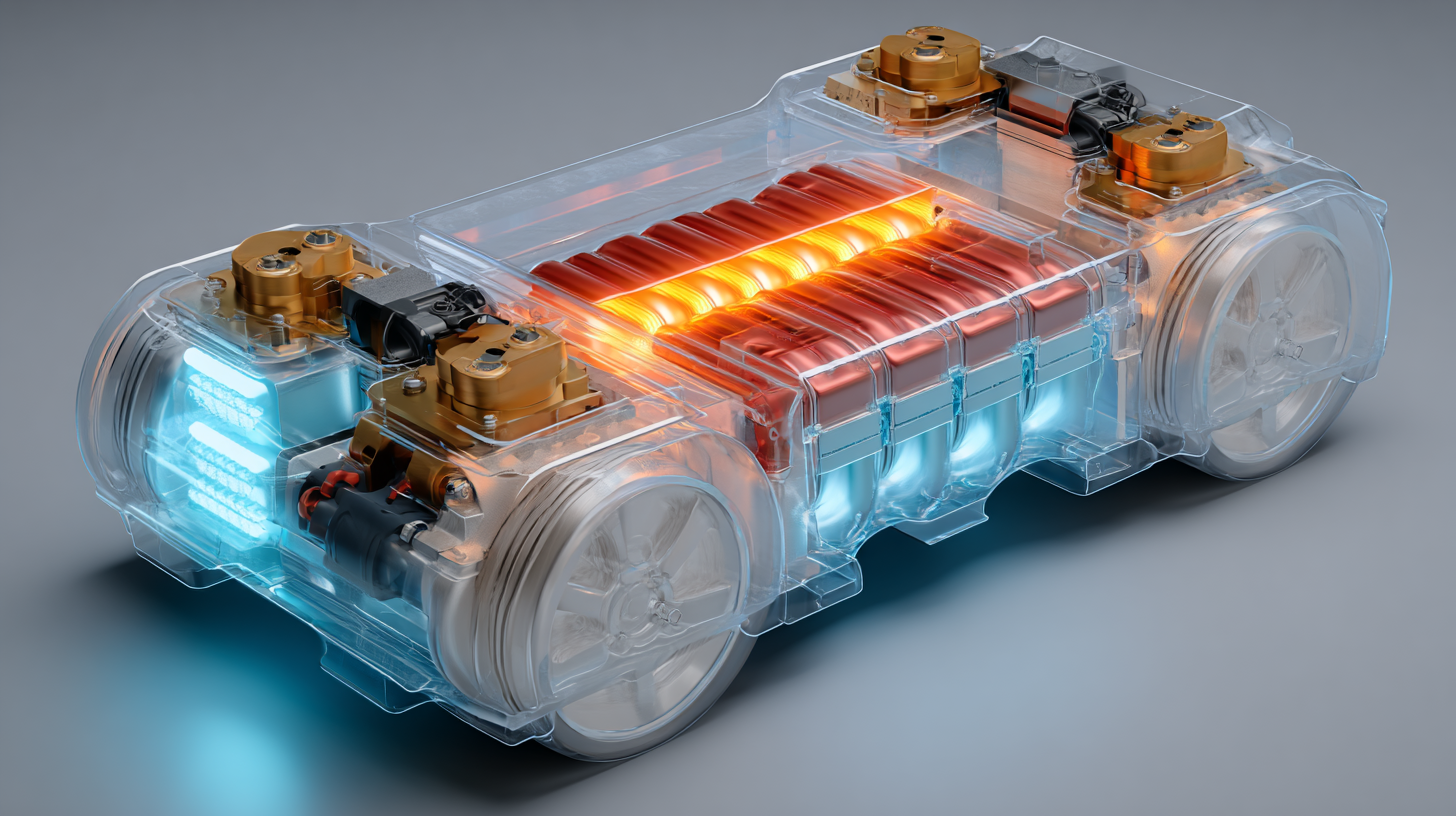

Electric vehicle (EV) molds play a pivotal role in the advancement of sustainable transportation, serving various key industry applications. As the global EV market is projected to reach $800 billion by 2027, with a compound annual growth rate (CAGR) of 22.6%, efficient mold technologies become indispensable in meeting rising production demands. Molds are essential for creating lightweight components that enhance energy efficiency, thereby optimizing the overall vehicle performance. For instance, manufacturers utilize advanced composite molds to produce battery enclosures and chassis parts, ensuring durability while minimizing weight.

Moreover, the integration of smart technologies into mold design is revolutionizing the manufacturing process. Real-time data analytics and automation reduce production time and costs, which is crucial as the automotive industry navigates escalating material prices and sustainability mandates. The International Energy Agency (IEA) reports that EVs could reduce global carbon dioxide emissions by up to 30% by 2030, underlining the critical importance of efficient mold production in the larger context of climate action. By investing in advanced molding technologies, the automotive sector not only meets regulatory requirements but also aligns with consumer demand for greener vehicles, solidifying the future of electric mobility.

The automotive industry is witnessing a significant shift towards electric mobility, primarily driven by the increasing demand for sustainable transportation solutions. One of the key factors contributing to this transformation is the evolution of electric vehicle (EV) manufacturing processes, particularly the molds used in their production. When comparing the costs associated with electric vehicle molds to traditional manufacturing methods, several advantages emerge that could revolutionize the way vehicles are produced.

Traditional manufacturing typically involves extensive tooling and longer production cycles, leading to higher costs and longer lead times. In contrast, modern electric vehicle molds are designed for efficiency and precision, significantly reducing manufacturing time and costs. These advanced molds facilitate rapid prototyping and allow for intricate designs that cater to the unique requirements of electric vehicles. With reduced material waste and energy consumption in the manufacturing process, the overall financial implications become more favorable for manufacturers looking to innovate in the electric mobility space.

Moreover, the adaptability of electric vehicle molds enables manufacturers to quickly respond to changing market demands and emerging technologies. This flexibility not only enhances cost-effectiveness but also supports the ongoing development of lighter, more efficient vehicles. As manufacturers increasingly adopt these molds, the traditional barriers of entry and cost in the automotive industry will continue to diminish, paving the way for a new era of sustainable and innovative transportation solutions.

The demand for electric vehicles (EVs) is expected to surge as we approach 2030, driven by advancements in technology and a growing focus on sustainability. With the global aluminum casting machinery market projected to reach approximately $6.5731 billion by 2025, the need for high-quality electric vehicle molds becomes increasingly significant. Manufacturers are seeking innovative solutions that not only improve production efficiency but also enhance the performance and longevity of vehicle components.

To adapt to these trends, manufacturers should consider investing in data-driven insights to refine their molding processes. Leveraging analytics can help identify areas for optimization, thereby reducing waste and improving product quality.

**Tip #1:** Regularly implement predictive maintenance protocols for casting machinery to avoid unplanned downtime and maximize productivity.

As the industry continues to evolve, staying ahead of future trends will be crucial. Understanding consumer preferences and environmental regulations will shape the development of electric vehicle molds, ensuring they meet the market's growing demands.

**Tip #2:** Engage with stakeholders throughout the entire production chain to ensure that the electric vehicle molds align with both industry standards and consumer expectations.

The automotive industry is witnessing a significant shift with the integration of electric vehicle (EV) molds, which has proven instrumental in the production of high-performance electric vehicles. A report from IDTechEx indicates that the global market for electric vehicle molds reached $4.3 billion in 2022, with projections to grow at a compound annual growth rate (CAGR) of 7.6% through 2030. Major automotive brands are leveraging advanced materials and innovative mold designs to enhance efficiency and reduce production costs.

For instance, Tesla has successfully implemented custom molds that streamline the manufacturing of their Model 3, resulting in a 30% reduction in production time. Similarly, Ford's investment in electric vehicle mold technology for their Mustang Mach-E has not only improved precision but also contributed to a 25% reduction in waste material during the manufacturing process. These case studies illustrate the transformative impact that cutting-edge mold technology can have on production systems across the industry.

**Tip:** When considering the adoption of electric vehicle molds, assess the materials used for durability and flexibility. Advanced composites can significantly enhance mold longevity, leading to cost savings in the long run. Additionally, leveraging data analytics during the design phase can optimize performance and aid in achieving sustainable manufacturing goals.