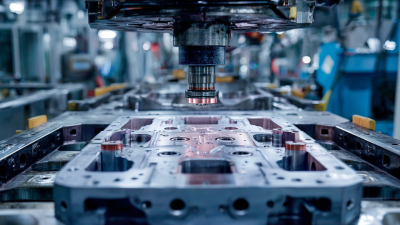

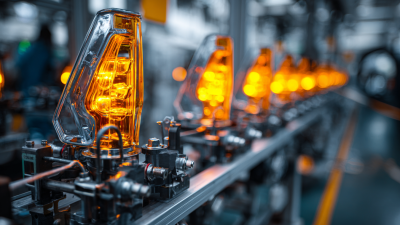

In the ever-evolving automotive industry, the efficiency of Automotive Mold production plays a critical role in determining overall manufacturing competitiveness. According to a report by MarketsandMarkets, the global automotive mold market is projected to reach USD 33.8 billion by 2026, growing at a CAGR of 6.1% from 2021. This significant growth underscores the increasing demand for high-quality molds that not only reduce production costs but also enhance product durability and performance. Various factors influence mold production efficiency, ranging from technological advancements in materials and design to optimized production processes. By implementing effective strategies, manufacturers can improve turnaround times and minimize waste, thereby ensuring a sustainable competitive edge in this high-stakes market. In this blog, we will explore the top strategies that can help in optimizing automotive mold production efficiency, enabling stakeholders to meet the burgeoning demands of the automotive sector.

In recent years, the automotive industry has seen a significant push towards optimizing mold production efficiency, driven by the need for lighter, thinner, and more aesthetically appealing components. The global automotive molds market is projected to grow from approximately $41.32 billion in 2024 to $60.88 billion by 2033, reflecting a compound annual growth rate (CAGR) of about 4.4%. This growth underscores the increasing importance of efficient manufacturing processes in meeting the demands of modern vehicle production.

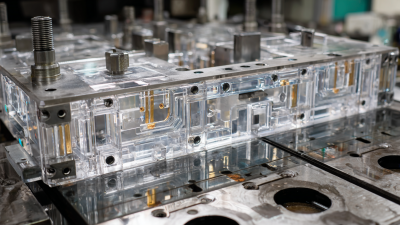

Key factors impacting automotive mold production efficiency include the integration of advanced technologies like 3D printing, which has revolutionized the speed and precision of mold creation. The global 3D printing market is anticipated to grow substantially, influenced by its application in developing intricate mold designs that require less material and time compared to traditional methods. Additionally, manufacturers are adopting innovations such as integrated die-casting techniques to reduce weight and increase efficiency, a shift that major automotive players are already embracing. As these strategies continue to evolve, the focus on optimizing mold production remains vital for sustaining competitive advantage in the automotive sector.

This bar chart illustrates the impact of various strategies on automotive mold production efficiency. The data represents efficiency improvement percentages for different optimization strategies.

In the fast-paced world of automotive manufacturing, optimizing mold production efficiency is pivotal to maintaining a competitive edge. Leveraging advanced technologies can significantly streamline the mold production process. One key innovation is the implementation of 3D printing, which allows for rapid prototyping and faster iteration cycles. This technology not only reduces lead times but also minimizes material waste, ultimately lowering production costs. As manufacturers integrate 3D printing into their workflows, they can create complex molds that were previously impossible or too costly to produce using traditional methods.

Another transformative technology is the use of integrated software solutions that facilitate real-time monitoring and analytics. By employing IoT sensors and advanced data analytics, manufacturers can gain insights into their production processes, identifying bottlenecks and inefficiencies. Moreover, predictive maintenance powered by machine learning can prevent equipment failures, ensuring smooth operation and minimal downtime. As these advanced technologies continue to evolve, automotive mold production can expect to see significant improvements in efficiency and output, enabling manufacturers to respond swiftly to market demands while maintaining high-quality standards.

In the competitive landscape of automotive mold production, implementing Lean manufacturing principles can significantly enhance operational efficiency. According to a report by the Society of Manufacturing Engineers (SME), organizations that adopt Lean practices can experience a 15-30% reduction in production lead time while also improving product quality and employee morale. Lean methodologies such as Value Stream Mapping and 5S organization can transform mold operations by streamlining workflows and minimizing waste—both of which are critical in the fast-paced automotive industry.

Moreover, the benefits of Lean are evidenced in the substantial cost savings realized by manufacturers. A study published in the Journal of Manufacturing Science and Engineering highlighted that automotive companies utilizing Lean techniques reported an average cost reduction of 20% in production processes. This includes savings from reduced inventory levels and more efficient resource allocation. By fostering a culture of continuous improvement and empowering employees to identify inefficiencies, automotive mold producers can not only enhance their productivity but also position themselves for long-term success in an industry characterized by rapid advancements and shifting consumer demands.

| Strategy | Description | Expected Efficiency Gain (%) | Implementation Complexity (1-10) |

|---|---|---|---|

| Value Stream Mapping | Analyzing the flow of materials and information to identify waste. | 15% | 4 |

| Standardized Work | Creating consistent methods for operations to reduce variability. | 20% | 5 |

| 5S Methodology | Organizing and managing the workspace and workflow effectively. | 10% | 3 |

| Kaizen | Implementing continuous improvement techniques across processes. | 25% | 6 |

| Just-In-Time (JIT) | Reducing inventory costs by producing only what is needed when it is needed. | 30% | 7 |

Enhancing workforce skills is crucial for improving mold production outcomes in the automotive industry. Just as educational reforms strive to personalize learning and improve teacher training to adapt to student needs, similar strategies can be applied to mold production. By focusing on targeted training programs that align with the latest industry techniques and technologies, automotive companies can ensure their workforce is equipped with the skills necessary for high-efficiency production.

Moreover, integrating advanced technologies like artificial intelligence into training initiatives can create a more responsive and effective learning environment. This approach parallels the push for future-proofing education for the next generation, emphasizing the importance of aligning skill sets with market demands. Consequently, companies that invest in workforce development by fostering a culture of continuous learning can enhance productivity and innovation, ultimately leading to better mold production outcomes.

To optimize automotive mold production efficiency, establishing effective quality control measures is crucial. According to recent industry reports, approximately 70% of production delays are attributed to quality issues. Implementing a robust quality assurance framework can significantly mitigate these challenges. Techniques such as Statistical Process Control (SPC) can help in monitoring production processes in real time, identifying anomalies before they escalate into larger problems.

To optimize automotive mold production efficiency, establishing effective quality control measures is crucial. According to recent industry reports, approximately 70% of production delays are attributed to quality issues. Implementing a robust quality assurance framework can significantly mitigate these challenges. Techniques such as Statistical Process Control (SPC) can help in monitoring production processes in real time, identifying anomalies before they escalate into larger problems.

Further insights from the metal forging market indicate a projected growth rate of 4.5% annually, driven by advancements in technology and a heightened focus on sustainability. These trends underline the importance of integrating environmentally-friendly practices in the mold production process, as manufacturers strive to meet both efficiency and ecological standards. By utilizing adaptive control systems and embracing automation, companies can enhance their quality control measures, ensuring a higher consistency in mold production while reducing waste. This holistic approach not only improves operational efficiency but also sets a foundation for future growth in the automotive sector.