In today's rapidly evolving manufacturing landscape, the strategy behind sourcing electronic molds has never been more critical. The demand for high-quality, efficient, and innovative electronic components drives the need for expertly crafted electronic molds that not only meet rigorous industry standards but also enhance product performance. This blog aims to delve into the top strategies for sourcing these essential molds, emphasizing the myriad benefits linked to effective sourcing practices. By unlocking efficiency and fostering innovation, manufacturers can ensure they stay ahead of the competition. This exploration will highlight the importance of understanding different mold types, evaluating suppliers, and integrating advanced technologies, all of which are vital for cultivating a successful electronic mold sourcing strategy in a dynamic market.

Traditional sourcing of electronic molds faces several significant challenges that can hinder efficiency and innovation. According to a report by the International Mold Steel Association, over 60% of manufacturers report difficulties in managing lead times and meeting tight production schedules. This is primarily due to outdated procurement processes and reliance on a limited network of suppliers. As mold design becomes more complex, the need for advanced materials and technologies further exacerbates these issues, leading to increased costs and project delays.

Moreover, the lack of real-time data and analytics in traditional sourcing workflows often results in poor decision-making. A recent study by the Global Industry Analysts indicates that companies leveraging data-driven sourcing strategies can reduce procurement costs by up to 15% while improving supplier relationship management. The slow adaptation to digital tools in mold sourcing not only impacts overheads but also constrains the ability to innovate. By recognizing these challenges and embracing modern sourcing strategies, manufacturers can unlock new levels of efficiency and drive competitive advantages in an increasingly digital marketplace.

In today's competitive landscape, sourcing electronic molds can pose various challenges, but innovative solutions can help overcome these obstacles and enhance operational efficiency. Companies must adopt a proactive approach to streamline their sourcing processes. One effective strategy is to leverage technology, such as digital sourcing platforms. These platforms facilitate real-time communication and collaboration between suppliers and manufacturers, allowing for quicker decision-making and minimized delays.

Another tip for overcoming sourcing obstacles is to develop strong relationships with suppliers. Building trust and communication can lead to long-term partnerships that enhance reliability and quality. Engaging suppliers in the design phase can bring valuable insights, enabling manufacturers to optimize mold designs and reduce production costs.

Lastly, diversifying the supplier base can significantly mitigate risks associated with sourcing. By exploring various suppliers across different regions, companies can avoid disruptions from market fluctuations. Emphasizing agility and flexibility in supply chain management will ensure that businesses can adapt to changing demands and maintain a steady flow of innovation.

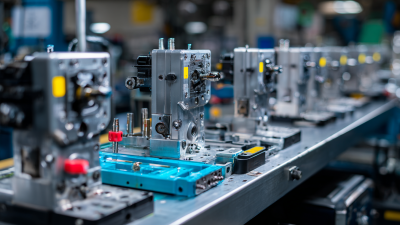

The landscape of mold procurement is rapidly changing with the advent of advanced technologies. In today's manufacturing environment, leveraging digital tools is essential for streamlining the sourcing of electronic molds.

Automation software and AI-driven platforms enable companies to analyze supplier performance, track pricing trends, and predict demand fluctuations. By integrating these technologies, businesses can not only reduce lead times but also enhance the quality of their mold procurement processes.

Furthermore, the role of technology extends beyond just sourcing. Cutting-edge solutions such as 3D modeling and simulation software allow designers to visualize molds before production, ensuring that prototypes meet specific requirements. This not only reduces waste and miscommunication but also fosters innovation by allowing for quick iterations. As manufacturers embrace these digital innovations, they position themselves to respond agilely to market demands while consistently improving efficiency and reducing costs.

Collaboration with suppliers in the mold industry is vital for achieving efficiency and driving innovation. As manufacturers navigate the complexities of sourcing electronic molds, adopting best practices in supplier collaboration can significantly enhance production capabilities. For instance, recent studies reveal that transparency in quality data and sustainable practices are key factors in building strong customer relationships. Companies that incorporate sustainability into their supply chain strategies are not only meeting regulatory demands but are also attracting environmentally-conscious consumers.

Moreover, leveraging technology and data sharing among stakeholders can foster innovation in mold production. With the shift towards localized production, a focus on short-notice production runs has emerged as a competitive advantage. According to industry reports, businesses that integrate advanced materials management can reduce waste and enhance process efficiency. This collaborative approach is essential for driving continuous improvement in the mold industry, enabling companies to adapt quickly to market changes while maintaining high standards of quality and safety. By prioritizing collaboration and innovation, manufacturers can unlock new levels of productivity and sustainability in electronic mold sourcing.

| Strategy | Description | Benefits | Challenges |

|---|---|---|---|

| Supplier Diversification | Engaging multiple suppliers to mitigate risks and enhance competitiveness. | Improved supply chain stability and access to a wider range of innovations. | Managing relationships and dependencies can become complex. |

| Technological Collaboration | Working closely with suppliers to leverage new technologies in mold design and manufacturing. | Enhanced product quality and reduced time to market. | Requires open communication and trust-building. |

| Cost Analysis | Regularly reviewing costs associated with sourcing molds to identify savings. | Optimizes budgeting and can lead to significant savings over time. | Requires effective data collection and analysis. |

| Sustainability Practices | Implementing eco-friendly practices in mold production. | Aligns with global trends and improves brand image. | Initial investment costs could be higher. |

| Performance Metrics | Establishing key performance indicators (KPIs) to measure supplier effectiveness. | Informed decisions can lead to higher efficiencies. | Requires continuous monitoring and adjustment. |

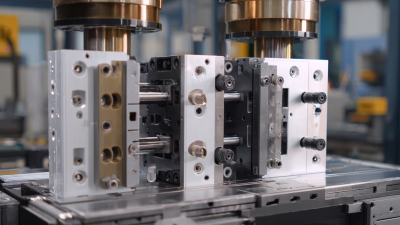

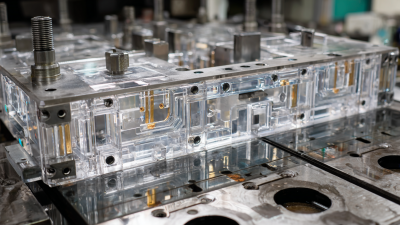

When sourcing electronic molds, evaluating quality and efficiency is paramount. According to a report from MarketsandMarkets, the global injection molding market is expected to reach USD 323.4 billion by 2025, driven by increasing demand for high-quality, precision components across various industries. A key strategy in ensuring quality is to conduct thorough supplier audits, including assessing their production capabilities and quality control measures. Consistent standards often translate into improved product lifecycle and reduced time-to-market, a crucial factor in today’s fast-paced technological landscape.

Efficiency can significantly impact lead times and costs in mold sourcing. A study by the Association for Manufacturing Technology (AMT) indicated that automation and advanced manufacturing technologies can reduce mold production time by 20-30%. Implementing lean manufacturing principles can also streamline operations, minimize waste, and enhance profitability. By prioritizing quality assessments and efficient sourcing strategies, businesses can unlock greater innovation potential, ultimately improving their competitive edge in an increasingly demanding market.