Choosing the right Electronic Mold is crucial in today's manufacturing landscape. According to Dr. Emily Carter, an expert in mold technology, "The precise choice of an Electronic Mold can significantly impact production quality." This statement highlights the importance of understanding various factors before making a decision.

There are numerous styles and specifications of Electronic Molds on the market. Each offers unique benefits and drawbacks. Many companies rush this choice, often leading to costly mistakes. Pay attention to the materials and design intricacies. Each detail counts in mold performance and product outcome.

Moreover, the process can feel overwhelming. Evaluating vendor credentials and service reliability is essential. Often, businesses overlook these aspects, which can lead to suboptimal results. It’s wise to consider past projects and user reviews. Reflecting on these elements can guide you in making a better-informed decision.

When it comes to electronic molds, understanding their basics is key. These molds are crucial in the manufacturing process. They shape and form various components like plastic and metals. What do they really do? They help create everything from simple gadgets to complex devices. This versatility makes them invaluable in many industries.

Choosing the right mold is not always straightforward. Different applications require different types of molds. Consider the material you’ll be using. Will it be flexible or rigid? Plastic molds offer lightweight solutions, while metal molds provide durability. Each choice can impact the end product more than you think. Manufacturers often overlook these factors, leading to costly mistakes.

Reflect on your specific needs. Are you looking for precision? Or is speed more important for your project? Balancing these factors can be tricky. Some molds may excel in one area but fail in another. Don’t rush into decisions. Take time to evaluate options and consider potential drawbacks. This process could save time and resources in the long run.

| Mold Type | Material Used | Applications | Durability | Cost Range |

|---|---|---|---|---|

| Injection Mold | Steel, Aluminum | Automotive Parts, Consumer Electronics | High | $5,000 - $100,000 |

| Compression Mold | Silicone, Thermosetting Plastics | Medical Devices, Seals | Medium | $1,000 - $50,000 |

| Blow Mold | Polyethylene, PVC | Bottles, Hollow Objects | High | $2,000 - $75,000 |

| Rotational Mold | Nylon, Polypropylene | Tanks, Playground Equipment | Medium | $3,000 - $60,000 |

| Die Cast Mold | Zinc, Aluminum | Automotive Components, Appliances | Very High | $10,000 - $250,000 |

Choosing the right electronic mold is crucial for any project. When evaluating options, consider several key factors. Material choice is essential. Different molds cater to varying applications. For instance, thermoplastics are versatile but may not suit high-temperature settings. Evaluate your project's specific needs.

Tips for selecting molds include examining the design complexity. Intricate designs need accurate molding. Poor design can lead to defects and higher costs. Additionally, pay attention to the mold's maintenance requirements. Some molds demand more upkeep, which can impact production efficiency.

Another important aspect is the mold's lifespan. A long-lasting mold can save money in the long run. However, cheaper options might not be durable. Weigh the cost against potential performance issues. Reflect on how often you will use the mold and for what types of products. This consideration will affect your decision significantly.

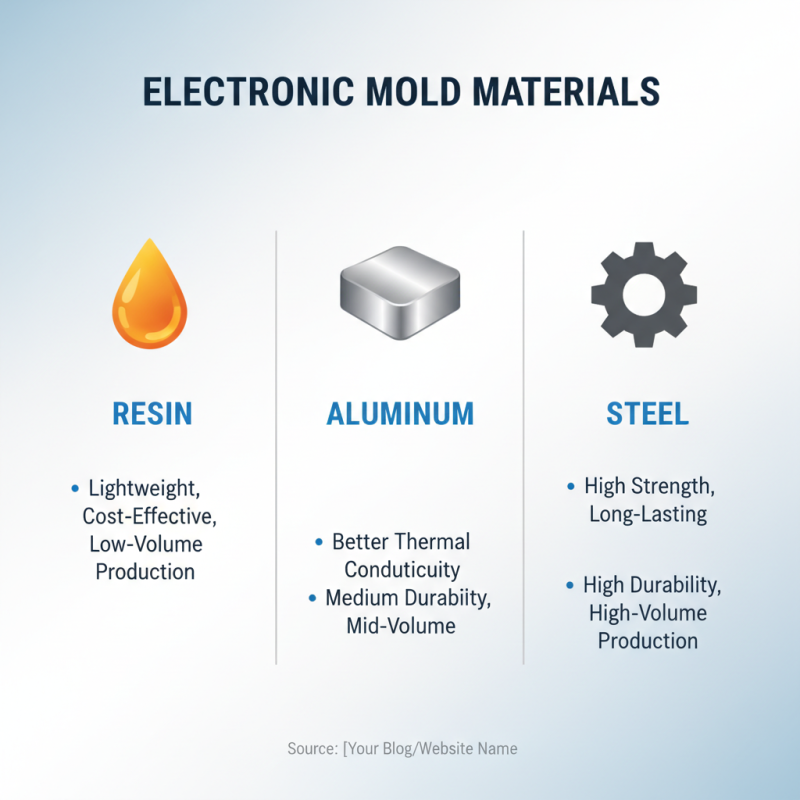

When selecting materials for electronic mold production, several factors come into play. The most common materials include resin, aluminum, and steel. Each has its unique properties and applications. For instance, resin molds are lightweight and cost-effective but may not provide the durability needed for high-volume production. Aluminum molds, on the other hand, offer better thermal conductivity and strength.

Selecting the right material is crucial. Here are some tips: consider the production volume. For low-volume runs, resin may work well. For larger production, aluminum or steel might be better. Assess the required precision. Some materials offer better dimensional stability, essential for intricate designs.

Another point to reflect on is the environmental impact. Certain resins can be less eco-friendly. Steel molds can be recycled, which is a positive aspect. Always think about the lifecycle of your chosen material. Seek out cost-effectiveness without sacrificing quality. Balancing these aspects will lead to better decisions in your electronic mold design process.

Choosing the right electronic mold is crucial for manufacturing success. A key factor to consider is the reputation of the manufacturer. Researching their background can provide insights into their reliability. Check their experience in the field. Have they worked with firms similar to yours? This can signal their understanding of your specific needs.

Visiting the manufacturer's facility can also help. Observe their operations and quality control processes. Ask for client references. Speaking with previous customers can reveal their satisfaction. Don’t shy away from discussing any inconsistencies in the manufacturer’s track record. Transparency is important.

Experience is not the only metric. Newer companies can bring fresh ideas. However, they should still demonstrate solid knowledge of the market. Gauge their ability to innovate while maintaining quality. These factors combine to create a fuller picture. A well-rounded assessment encourages a more informed decision.

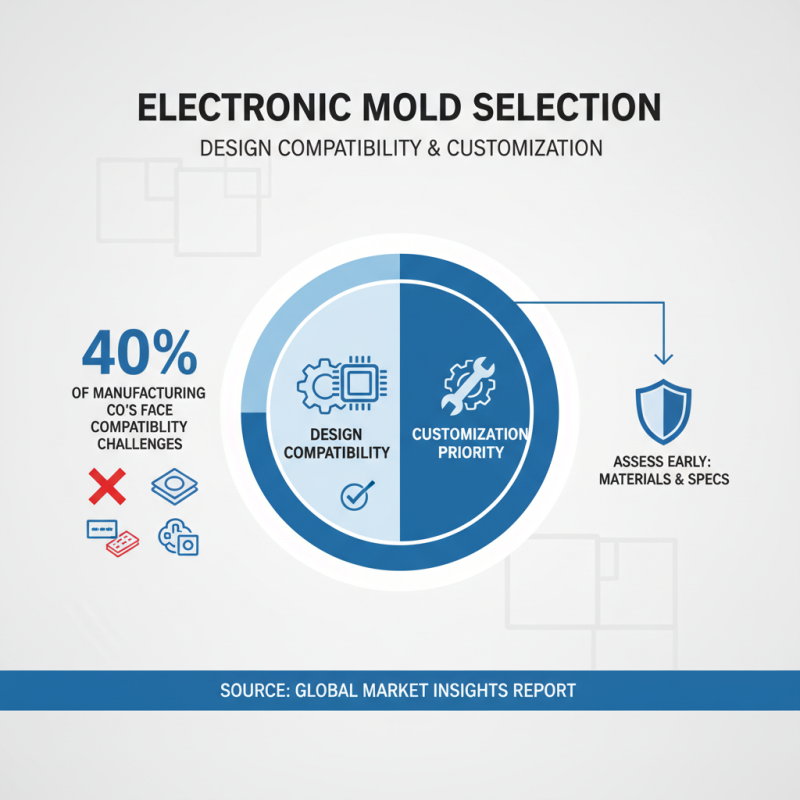

When choosing electronic molds, design compatibility and customization are crucial. A recent report by Global Market Insights states that 40% of manufacturing companies face challenges in mold compatibility with their designs. This is often due to differences in materials or specifications. Thus, assessing compatibility should be a priority.

Customization options can enhance mold performance. A study indicates that tailored molds can increase production efficiency by up to 30%. Manufacturers need to communicate their design needs clearly. However, misunderstandings often arise. Specifications might be misinterpreted, leading to delays and increased costs.

Understanding the materials is also essential. Molds made from the wrong material can fail during the production process. This can result in defects or even equipment damage. Many manufacturers overlook this aspect, assuming all materials perform equally. It's vital to conduct thorough research on material properties before making decisions.