Container mold is a growing concern in many industries. It can affect product quality, safety, and shelf life. Experts emphasize the importance of prevention. Dr. Sarah Thompson, a mold remediation specialist, stated, "Understanding container mold is vital for maintaining product integrity."

Mold thrives in damp environments. Containers are often closed and humid, creating the perfect breeding ground. Regular inspection and proper storage methods can mitigate risks. Using moisture-absorbing materials within containers is one effective solution.

However, organizations often overlook container mold until it's too late. Understanding its impact should be a priority. This awareness can lead to more informed choices and effective prevention strategies. Adopting best practices is essential for anyone dealing with container mold. Every step taken can significantly reduce mold occurrence and promote safety.

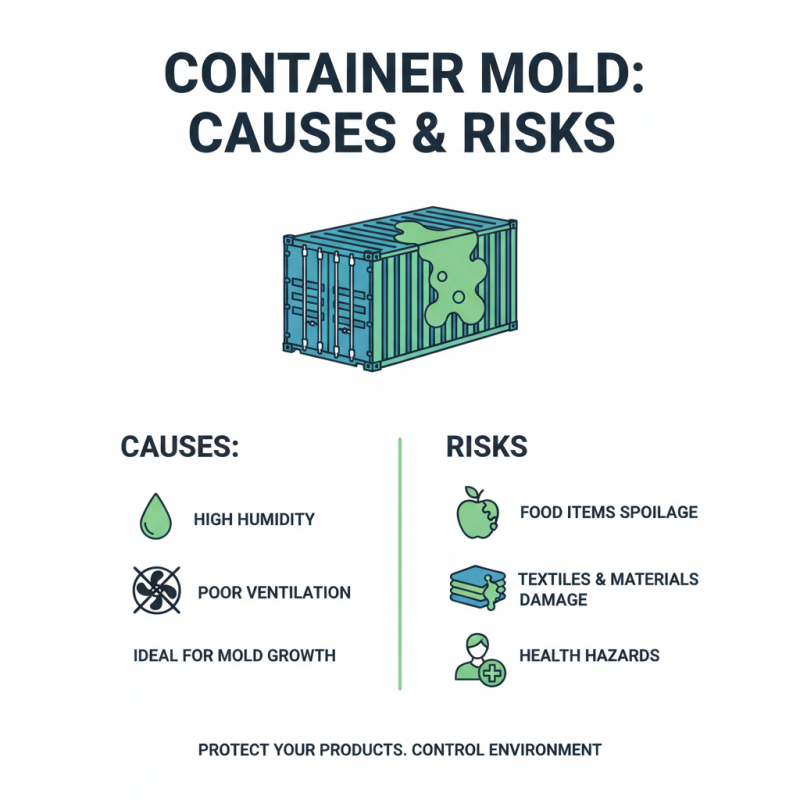

Container mold is a common issue that affects many products. Understanding its causes is crucial. High humidity and poor ventilation create ideal conditions for mold growth. Food items, textiles, and materials can all suffer in mold-prone environments. Once established, mold can damage contents and lead to health risks.

To prevent mold, consider environmental factors. Keep storage areas dry. Use dehumidifiers if necessary. Regularly inspect containers for moisture. Use moisture-absorbing materials to mitigate risk. Seal containers properly to limit air exposure. Even the best containers can fail if environmental control is lacking.

It's important to reflect on how easily mold can develop. Often, hidden corners and crevices go unnoticed. Some may think that simply cleaning a container suffices. In reality, thorough inspections are key. Mold spores can linger, resurfacing if conditions remain unchanged. Awareness and proactive measures are essential for effective prevention.

Mold can be a significant challenge in container storage. It thrives in damp and warm conditions. Understanding how to prevent it is crucial for maintaining the quality of stored goods. One effective method is using moisture-absorbing materials. Silica gel packets can help keep humidity levels low. These are an easy and cost-effective solution.

Regularly inspecting containers is essential. Check for leaks and signs of moisture. Often, we overlook minor issues until they become bigger problems. Sealing containers properly is another effective prevention method. Use airtight seals to deter moisture entry. However, it’s important to remember that not all seals are created equal; some may wear down or fail over time.

Ventilation can also make a difference. Containers should have proper airflow to help reduce humidity. This aspect is often neglected, leading to mold growth. Using fans can be a temporary solution but is not always practical. Lastly, keeping storage areas clean and dry should be a routine task. Removing debris can seem tedious, but it plays a vital role in prevention. Ignoring such details might lead to mold issues down the road.

This chart illustrates the effectiveness of different mold prevention solutions for containers, measured by their effectiveness rating on a scale of 1 to 10. A higher rating indicates a more effective solution for preventing mold growth.

Cleaning and sanitizing containers is crucial for mold prevention. Mold spores can thrive in damp, unclean environments. It is essential to develop a consistent cleaning routine. Start by using hot water and a safe detergent for all containers. This helps in removing residue that may harbor mold. More thorough inspections are necessary, especially after each use.

Using sanitizers can significantly reduce mold risks. Make sure to choose effective sanitizing solutions. Follow the recommended dwell time stated on the product. This allows the sanitizer to work effectively. In many cases, it is useful to air-dry containers after cleaning. This simple step can prevent moisture accumulation.

Employing a dedicated cleaning schedule for containers keeps the workspace effective. It's easy to overlook the importance of cleanliness in container handling. Reflection on past practices can identify areas for improvement. Consider whether all team members are following the same protocols. Addressing inconsistencies in cleaning habits can lead to better outcomes.

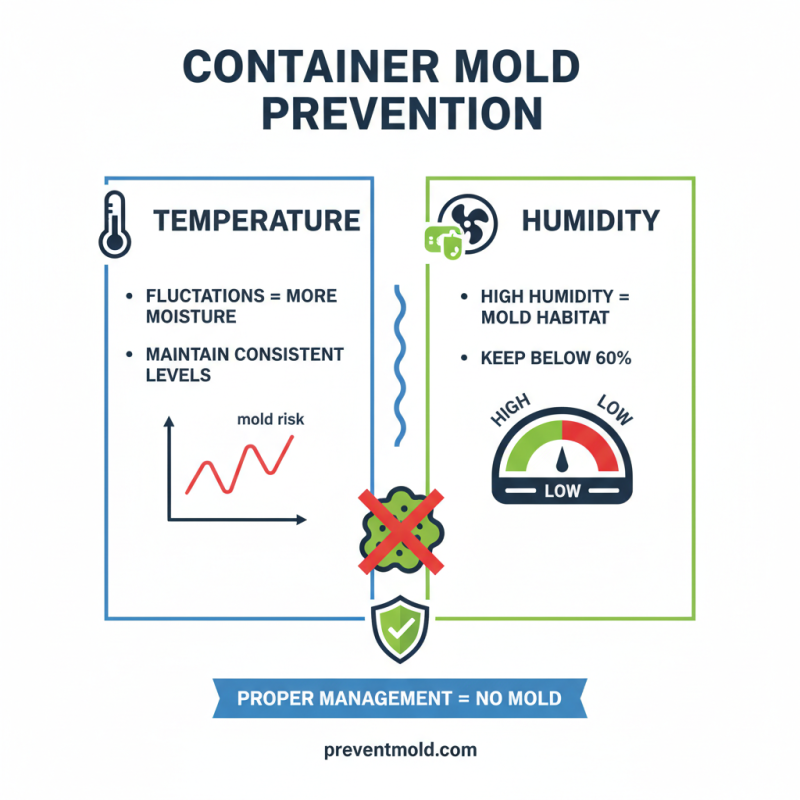

Temperature and humidity play critical roles in mold development. Proper management of these environmental factors is essential to prevent container mold. High humidity can create a perfect habitat for mold. Even a small temperature fluctuation can impact moisture levels.

Monitoring the temperature inside containers should be a routine task. Maintaining a stable environment often proves challenging. Humidity can change drastically, especially during transport. Simple tools like hygrometers can help track moisture levels effectively. Moreover, ensuring that containers are dry before storage is crucial. Mold can thrive in damp conditions, even with minimal exposure.

Regular inspections are vital as well. Small signs of mold can be easy to overlook but are often a precursor to larger problems. Understanding the specific conditions that foster mold growth is necessary. Adjustments may need to be made based on seasonal changes. Implementing effective environmental controls requires ongoing effort and consistency.

Regular inspection and maintenance are essential for mold control in container environments. It’s not just about the visible signs but hidden growth too. Mold can thrive in dark, damp areas. Inspect containers often to catch problems early. Look for leaks or water stains. Pay attention to corners and vents, as these are common trouble spots.

After inspections, maintenance becomes crucial. Ensure proper ventilation in storage areas. Stagnant air can lead to moisture accumulation. Consider using desiccants to absorb humidity. They are simple yet effective. Regularly cleaning surfaces will also reduce mold spores. Use mild detergents to avoid harsh chemicals that might damage materials.

Despite all precautions, mold can still find a way. It often requires constant vigilance. Sometimes, contamination happens even in seemingly perfect conditions. Learning from these experiences helps improve future prevention strategies. Share findings with your team for collective awareness. Mold control is a shared responsibility that needs continuous effort.