In today's highly competitive manufacturing landscape, the implementation of Advanced Mold Technology has become a crucial factor for achieving superior product quality. According to a recent report by the International Association of Mold Makers, companies utilizing advanced molding techniques have seen a significant 25% reduction in defect rates and a 30% increase in production efficiency. These metrics highlight the necessity for manufacturers to adopt these innovative technologies to remain competitive and satisfy growing consumer demands for higher-quality products.

Industry expert Dr. Emily Parker, a leading authority in polymer engineering, emphasizes the importance of embracing these innovations: "Advanced Mold Technology not only enhances product precision but also allows for greater flexibility in design, enabling manufacturers to meet specific customer needs and market trends." By leveraging advanced techniques, such as multi-material molding and precision cooling systems, businesses can enhance their production capabilities while ensuring consistent quality across their product lines.

As we explore the "Top 10" strategies for utilizing Advanced Mold Technology, it becomes clear that integrating these practices can lead to transformative changes in manufacturing processes, ultimately paving the way for increased customer satisfaction and long-term business success. The following sections will delve deeper into these strategies, providing actionable insights for manufacturers looking to elevate their product quality through advanced molding solutions.

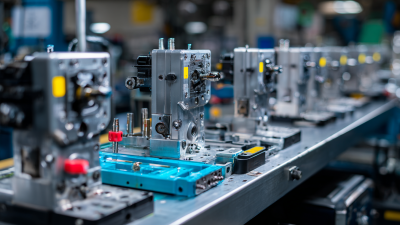

The evolution of advanced mold technology has revolutionized the manufacturing industry, significantly enhancing product quality and efficiency. According to a report by MarketsandMarkets, the global mold market is projected to reach USD 24.5 billion by 2025, driven by the demand for precision engineering and innovative materials. This surge reflects the industry's shift towards adopting advanced technologies, such as CAD/CAM systems and 3D printing, which facilitate more complex mold designs and reduce lead times.

One pivotal advancement is the integration of smart manufacturing technologies into mold production. IoT-enabled molds can monitor performance in real-time, allowing for proactive maintenance and reduced downtime. A study by McKinsey indicates that manufacturers leveraging smart technologies could see a productivity increase of 20-30%. This approach not only enhances product quality but also leads to significant cost savings.

**Tip:** To harness the benefits of advanced mold technology, manufacturers should invest in training their workforce on new tools and technologies. Ensuring your team is skilled in the latest techniques will maximize the potential of modern mold systems.

Moreover, utilizing simulation software for mold design can minimize material waste and improve product consistency. As per a report from AM R&D, effective simulation can reduce production errors by up to 50%, leading to higher product quality and customer satisfaction.

**Tip:** Regularly review and upgrade your simulation tools to stay competitive in the ever-evolving manufacturing landscape.

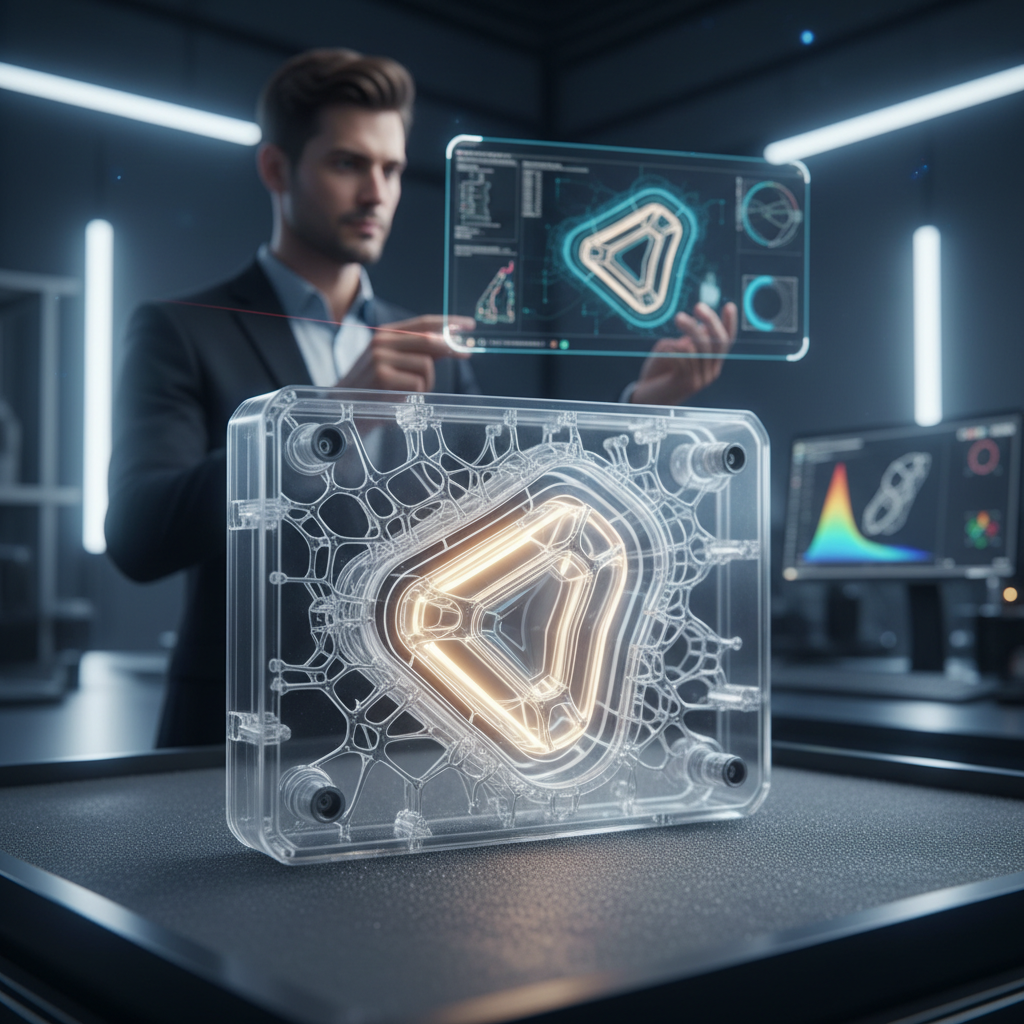

The integration of 3D printing technology into mold design brings forth key benefits that can significantly enhance product quality. One of the primary advantages is the ability to create complex geometries that traditional manufacturing methods struggle to achieve. This capability allows designers to innovate and produce unique, high-performance products tailored to specific applications.

Tips: When utilizing 3D printing for mold design, consider the material selection carefully. Different 3D printing materials can affect the mold's durability and the final product's quality, so choose one that aligns with the operational requirements.

Moreover, the speed of prototyping is greatly enhanced with 3D printing. Changes to the mold design can be implemented quickly, reducing lead times and allowing for rapid iterations. This agility enables manufacturers to respond more swiftly to market demands and customer feedback, ensuring that the final product aligns perfectly with expectations.

Tips: Always keep your communication channels open with the design and production teams during the 3D printing process. Collaborative feedback can help identify potential design flaws early and improve overall product quality before full-scale production begins.

The implementation of advanced mold technology has shown significant potential in driving cost reductions across various industries. Recent industry statistics reveal that adopting innovative molding techniques can lead to a reduction in production costs by up to 30%. This not only streamlines manufacturing processes but also minimizes materials waste, enhancing overall efficiency. Such advancements allow manufacturers to produce higher volumes of quality products faster, which is critical in meeting market demands and maintaining competitive pricing.

Additionally, the investment in advanced mold techniques often results in longer-lasting tools and reduced maintenance needs. By utilizing sophisticated materials and precision engineering, businesses can expect fewer breakdowns and interruptions in production, translating to more predictable output timelines. As industries increasingly adopt these technologies, the cumulative effects contribute to lower operational costs and the ability to allocate savings toward further innovation and development. These statistics underscore the economic advantages of advanced molding practices, making them essential for companies aiming to enhance product quality while optimizing their bottom lines.

The integration of advanced mold technology in production processes has proven to enhance product quality significantly. One notable case study involves a leading automotive manufacturer that adopted precision injection molding techniques. By implementing advanced mold solutions, this company reduced cycle times and minimized defects, resulting in superior fit and finish in their vehicle components. The use of CAD software and simulation technology allowed for precise mold designs that catered to the specific requirements of high-performance parts, showcasing a marked improvement in overall production efficiency.

Another example can be seen in the consumer electronics sector, where a company specializing in smartphone manufacturing introduced advanced mold capabilities to create complex geometries for their devices. By leveraging multi-cavity molds and automated systems, the manufacturer achieved greater consistency in product quality. The enhanced mold technology not only allowed for intricate designs but also facilitated faster production rates, meeting the rising consumer demand without compromising on quality standards. These case studies demonstrate that advanced mold technology can serve as a transformative tool in various industries, fostering innovation and competitive advantages.

As we approach 2025, the advancements in mold technology are expected to significantly enhance product quality across various industries. Emerging trends, such as the integration of AI and advanced materials, are predicted to revolutionize mold design and manufacturing processes. The continuous evolution of thermosetting plastics, particularly melamine-based materials, aligns with the demand for products that are both durable and aesthetically pleasing. This shift indicates a strategic movement towards optimizing production efficiency and minimizing waste.

In addition, as industries like automotive and consumer goods evolve, the focus will increasingly be on innovation-driven solutions. The importance of precision in mold technology cannot be overstated, as it directly influences product reliability and safety. With the influx of data-driven analytics, manufacturers are likely to implement smarter processes in mold creation, further supporting advanced quality assurance measures. Companies that embrace these changes by 2025 will lead the way in setting new standards for quality and efficiency in manufacturing.

| Technology Type | Key Features | Predicted Impact by 2025 | Industry Application |

|---|---|---|---|

| 3D Printing Technology | Rapid prototyping, customization, reduced waste | Increased efficiency and reduced lead times | Consumer Electronics, Automotive |

| Digital Mold Design | Simulation software, virtual testing | Enhanced accuracy and product performance | Medical Devices, Aerospace |

| Advanced Materials | Lightweight, durable, and temperature-resistant | Improved product longevity and sustainability | Construction, Transportation |

| Smart Mold Technology | IoT integration, real-time monitoring | Reduced downtime and maintenance costs | Manufacturing, Robotics |